Production method of spherical graphite

A technology of spherical graphite and its production method, which is applied in the field of spherical graphite, can solve problems such as changes in the bearing structure of the main engine, influence on the electrochemical performance of spherical graphite, and increase in iron content, and achieve excellent charge-discharge performance and cycle performance, and reduce irreversible capacity loss. The effect of low content of harmful elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

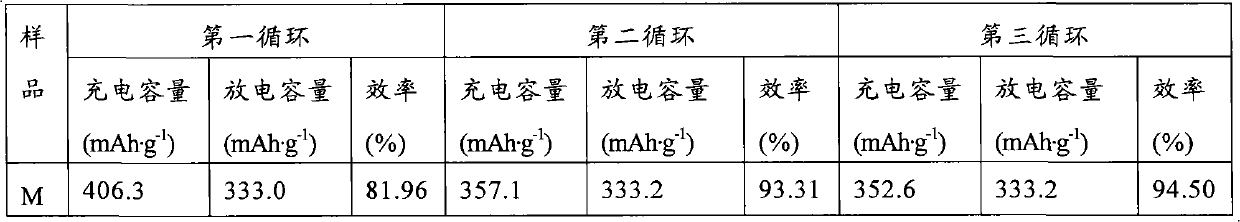

Examples

Embodiment 1

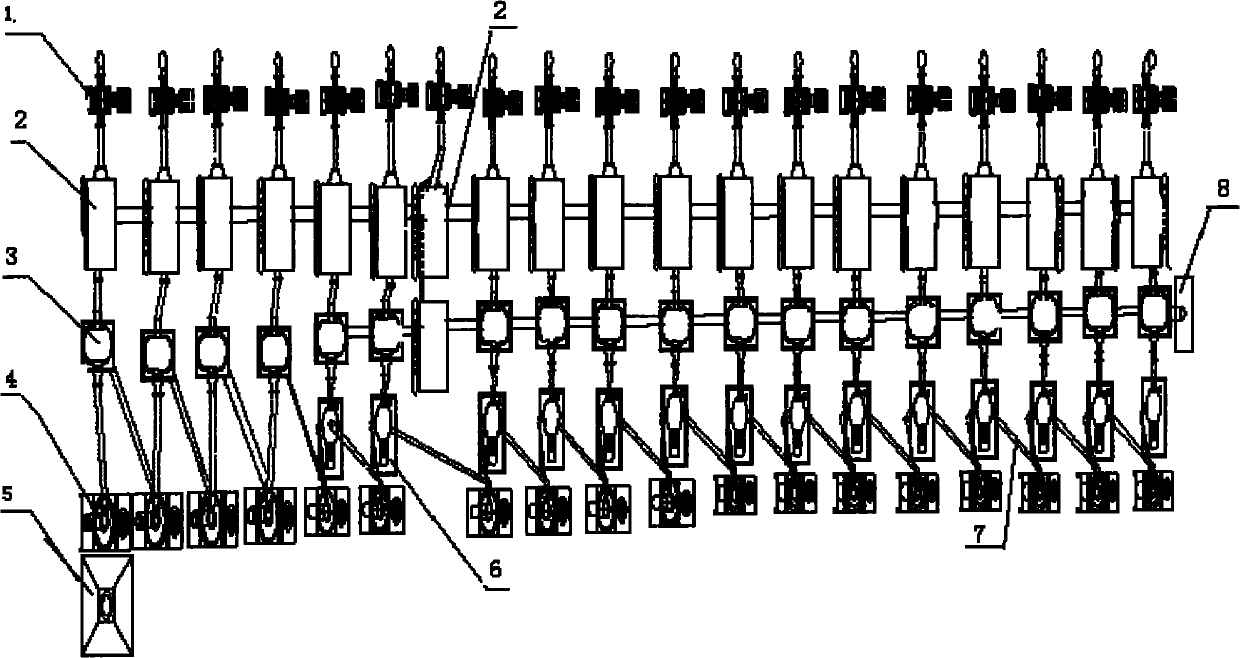

[0073] The flake graphite with a specification of -100 mesh and a carbon content of 95% is first passed through a 80 mesh sieve, using such as Figure 6 The shown spheroidizing equipment performs spheroidizing and shaping of graphite. Figure 6 The online spheroidization equipment adopts the online mode of the method of the present invention for 18 groups of devices. These 18 groups of devices are arranged in sequence from left to right as Group 1, Group 2, Group 3... Group 18. There is a centralized dust collector between the 6th group device and the 7th group device.

[0074] Groups 1-4 include Roots blower (1), dust collector (2), cyclone separator (3) and pulverizer (4) in turn, wherein the pulverizers (4) in these 4 groups are all ACM60 machines, The grinding blocks on the rotor are all square grinding blocks; the connection between each group of devices is that the feeding port of the cyclone separator of the previous group of devices is connected with the feeding port...

Embodiment 2

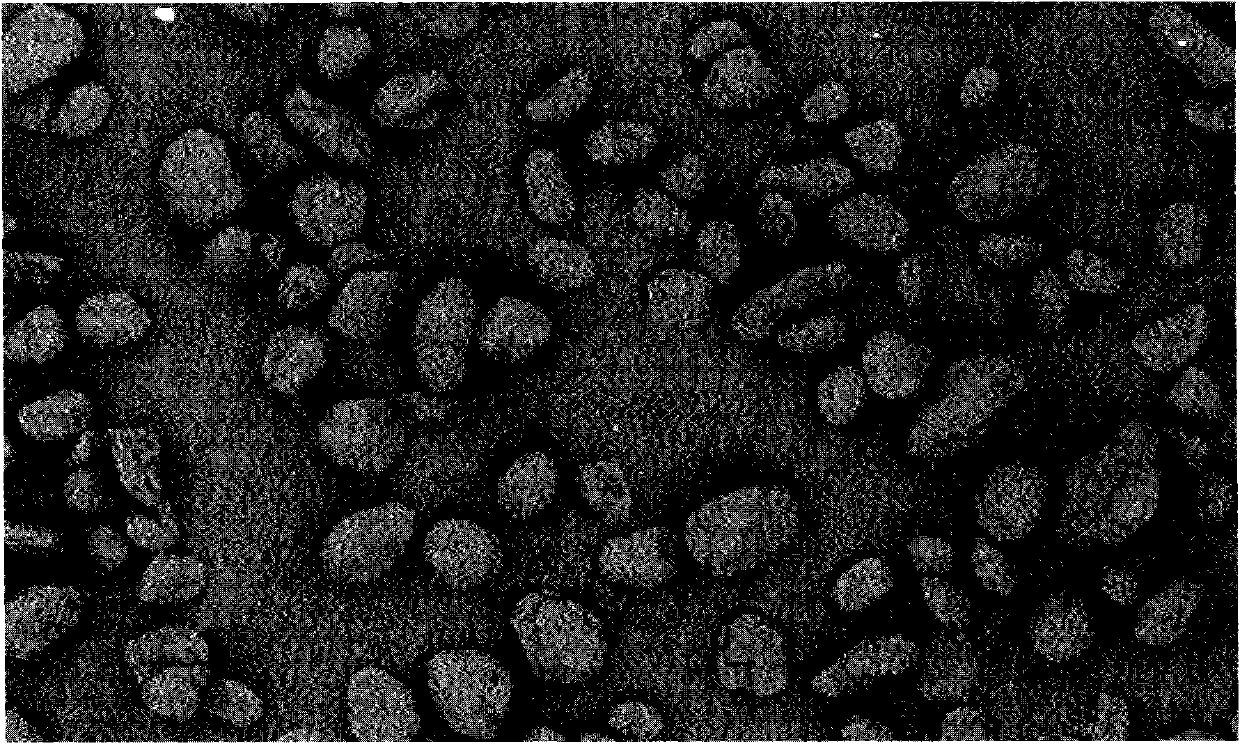

[0094] The flake graphite (such as image 3 (shown) pass through a 100-mesh sieve, and then use the spheroidizing equipment consisting of 9 sets of devices arranged in sequence from left to right for spheroidizing and shaping. The on-line mode of the spheroidizing device is: the feeding port of the cyclone separator in the first group device is connected with the feeding port of the pulverizer in the second group device, and the feeding port of the cyclone separator in the second group device is connected with the feeding port of the third group device The feeding port of the pulverizer is connected, and so on, until the ninth group of devices. Among them, the pulverizing machine uses 3 ACM-60 machines, 3 ACM-50 machines and 3 ACM-30 machines sequentially from the first group of devices to the ninth group of devices. The grinding blocks on the rotor of each ACM-30 machine are a combination of square grinding blocks and cylindrical grinding blocks. A square grinding block is ...

Embodiment 3

[0101] Flake graphite with a specification of +100 mesh and a carbon content of 97% first passes through a 50 mesh screen, and then enters the spheroidizing equipment consisting of 6 sets of devices arranged in sequence from left to right for spheroidizing and shaping. The on-line mode of this spheroidizing device is similar to that of embodiment 2, that is, the feeding port of the first group device cyclone separator is connected with the feeding port of the second group device pulverizer, and the feeding port of the second group device cyclone separator is connected with the feeding port of the second group device cyclone separator. The feeding ports of the pulverizers in the third group of devices are connected, and so on, until the sixth group of devices, where the pulverizers use 2 ACM-60 machines, 2 ACM-50 machines and 2 ACM-30 machines in turn. For the grinding blocks on the rotors of the 2 ACM-30 machines, one is a square grinding block and the other is a cylindrical gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com