Diffuser and manufacturing method thereof

A manufacturing method and a technology for a diffuser, which are applied in chemical instruments and methods, water aeration, sustainable biological treatment, etc., can solve the problems of reduced oxygen transmission efficiency, poor impact resistance and wear resistance, and short service life, and achieve Excellent durability, air tightness and air permeability, improved wear resistance and impact resistance, high oxygen transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

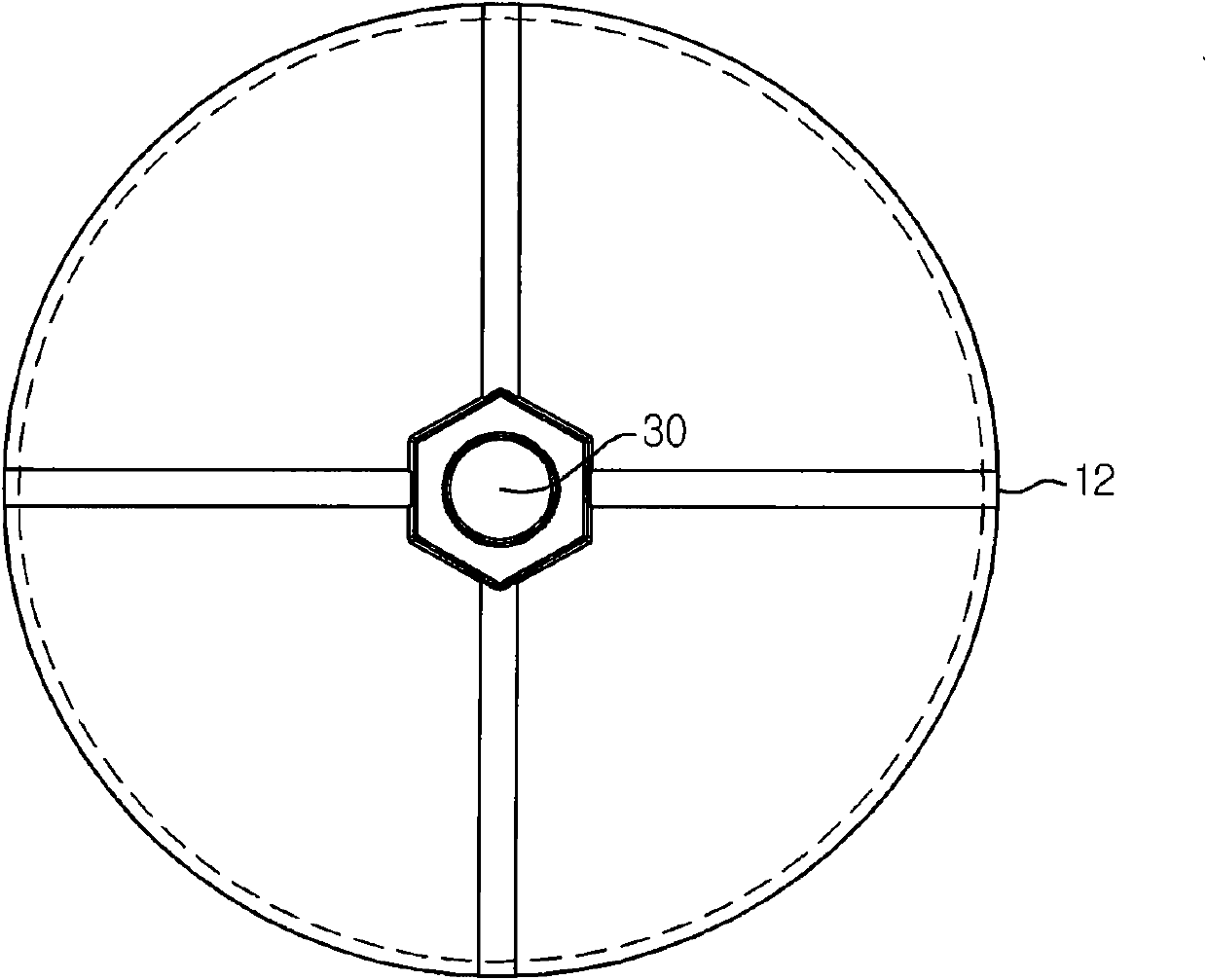

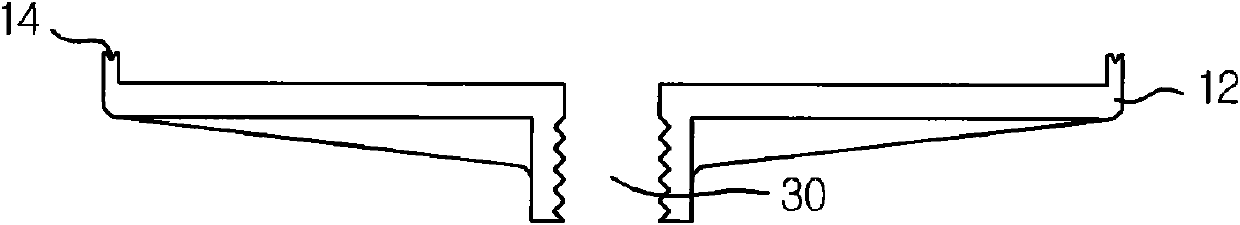

[0032] Figure 1a It is a longitudinal sectional view of the upper body 11 with a plurality of diffuser openings 20; Figure 1b It is a longitudinal cross-sectional view of the lower body 12 having the air supply port 30 .

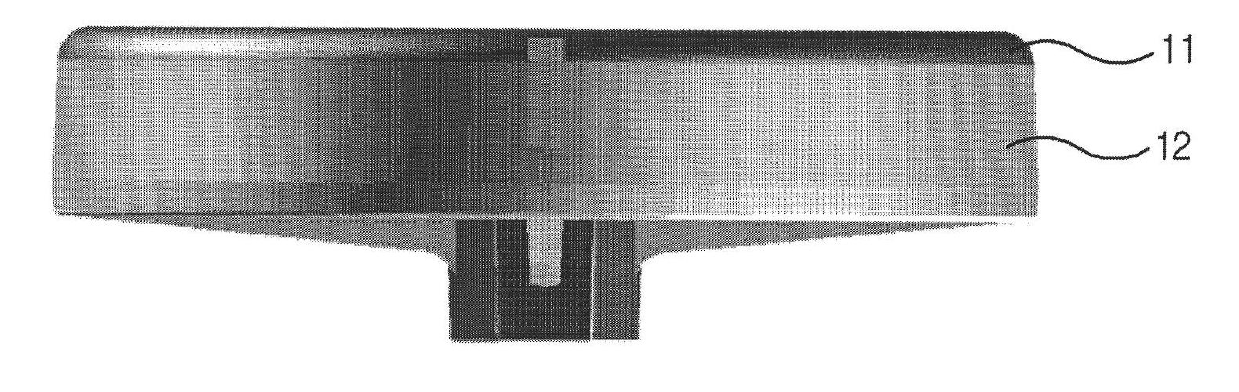

[0033] The above-mentioned main bodies 11, 12 formed by the above-mentioned upper main body and the lower main body are welded to each other at the joint part 14, and after being combined into one main body, the structure is as follows: image 3 As shown in the air diffuser 1 , a space 13 through which air can circulate is formed inside the air diffuser 1 .

[0034] Wherein, the above-mentioned diffuser pipe 1 can be combined by thermal welding, that is, the joint parts of the main bodies 11 and 12 made of thermoplastic synthetic resin are heated with an electric heating plate, and the surfaces are melted and then crimped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com