Reciprocating type hydraulic diaphragm pump without three-way valve device

A hydraulic diaphragm pump, reciprocating technology, applied to pumps with flexible working elements, pumps, liquid variable capacity machinery, etc., can solve the problems of short service life, complex structure, high debugging requirements, etc., to achieve long service life and guarantee Operating environment and reduction of maintenance time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] With reference to accompanying drawing, further illustrate the present invention:

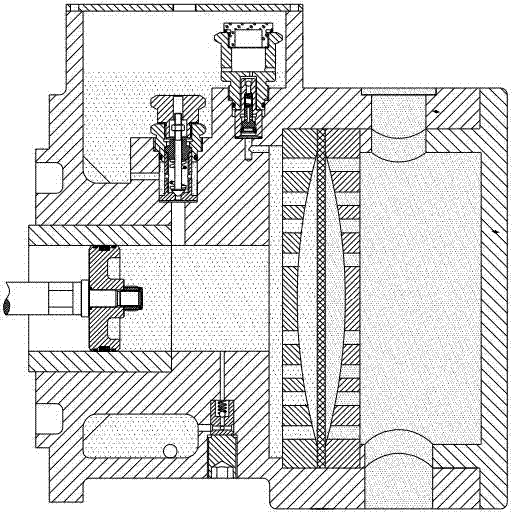

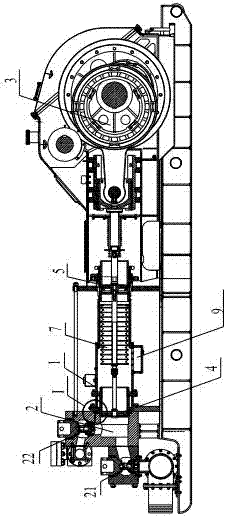

[0038] A reciprocating hydraulic diaphragm pump without a three-valve device includes a hydraulic cylinder 1 and a piston that is adapted and sealed to the hydraulic cylinder 1. The front end of the hydraulic cylinder 1 is provided with a medium chamber 2 for containing the conveying medium. The rear end of the hydraulic cylinder 1 is provided with a power device 3 that pushes the piston to reciprocate axially along the hydraulic cylinder, and the piston is linked with the power device 3 through a piston rod;

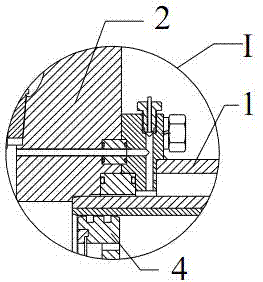

[0039] The piston includes a diaphragm piston 4 connected to the medium chamber 2 and a transmission piston 5 connected to the power unit, the diaphragm piston 4 is connected to the transmission piston 5 through a connecting rod 6, and the The external diameter of described diaphragm piston 4 is identical with transmission piston 5;

[0040] The diaphragm piston 4 includes a pist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com