Leakage monitoring and warning system of large fiber-grating liquid gas storage tank

A technology of liquefied gas storage tanks and optical fiber gratings, which can solve the problem of leakage of large liquefied gas storage tanks that is difficult to reach by detecting the appearance of fluid at the leak point, using liquid/vacuum degree for liquid tightness measurement, and measuring devices. Long-term, real-time online monitoring and early warning issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings.

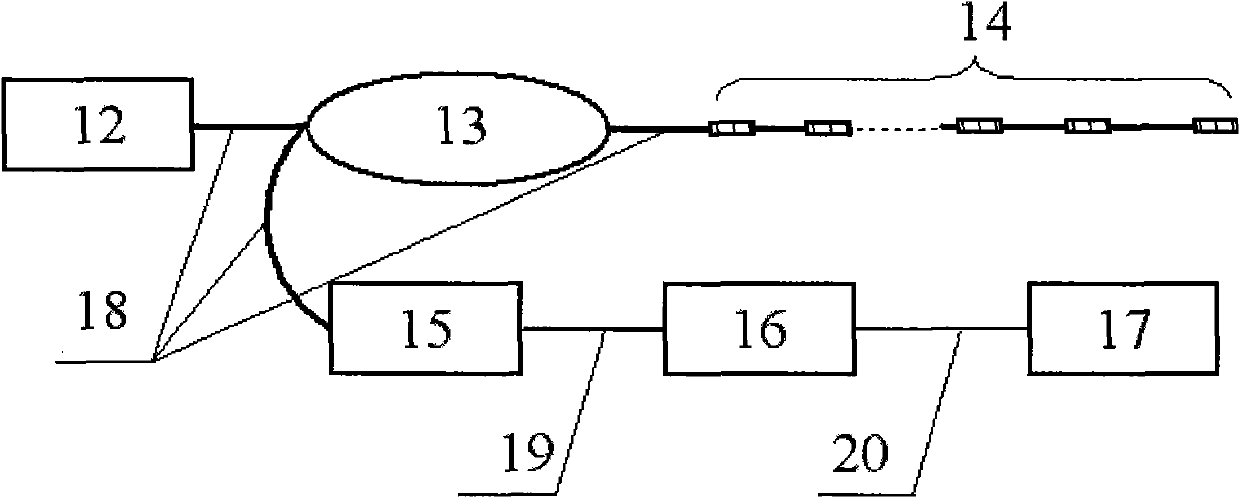

[0039] According to the size of the storage tank and the space interval of the probes, determine the total number of fiber grating temperature probes, the number of groups of identical fiber gratings and the number of gratings of each group of identical fiber gratings, and use the same specification of optical fiber to make several groups of full Same as fiber grating.

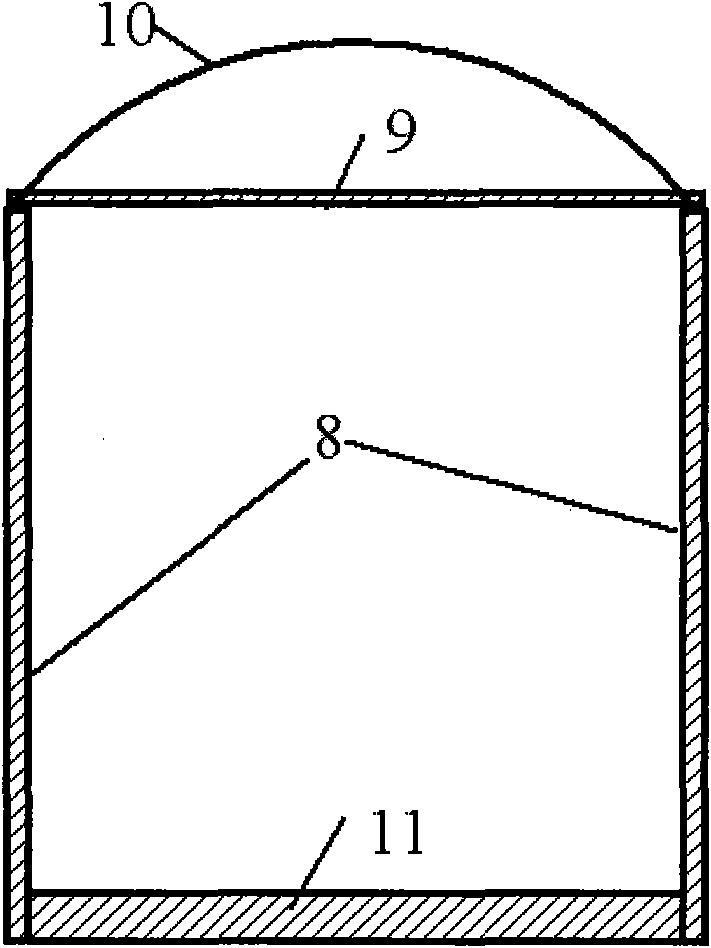

[0040] These optical fiber grating temperature probes are connected at regular intervals to form probe strings, respectively surrounding each marking area installed on the same horizontal plane at the bottom of the tank wall. Among them, the first probe (0# probe) is used to monitor the ambient temperature, and the rest of the probes are installed close to the tank wall to monitor the temperature of the tank wall.

[0041] The optical fiber is used to connect the fiber grating temperature probe to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com