Strong-ampere energy-saving explosion-proof electric heater

An electric heater, energy-saving technology, applied in the direction of ohmic resistance heating parts, heating elements, etc., can solve the problems of insufficient connection strength, influence of welding parts, dispersion, etc., to eliminate potential safety hazards, improve insulation performance, and improve safety performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

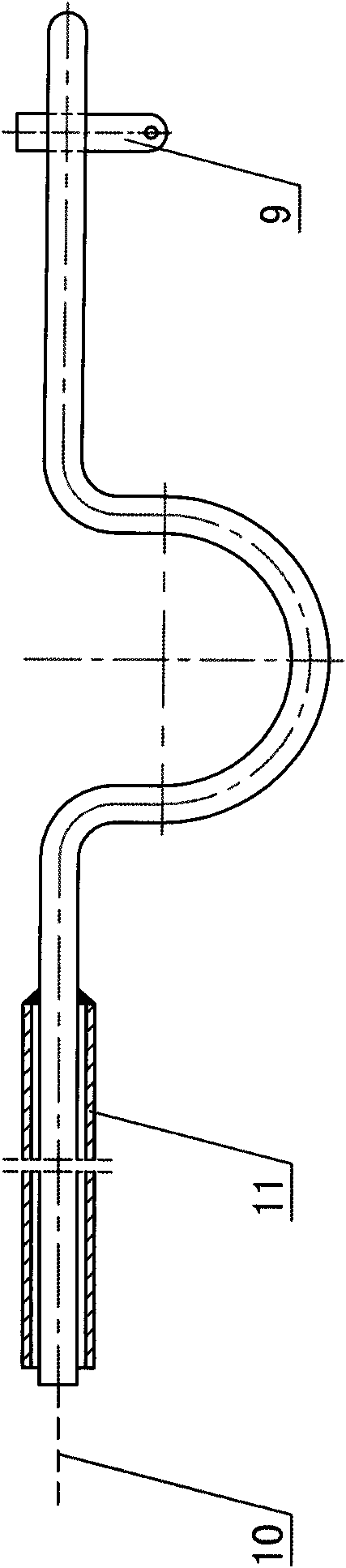

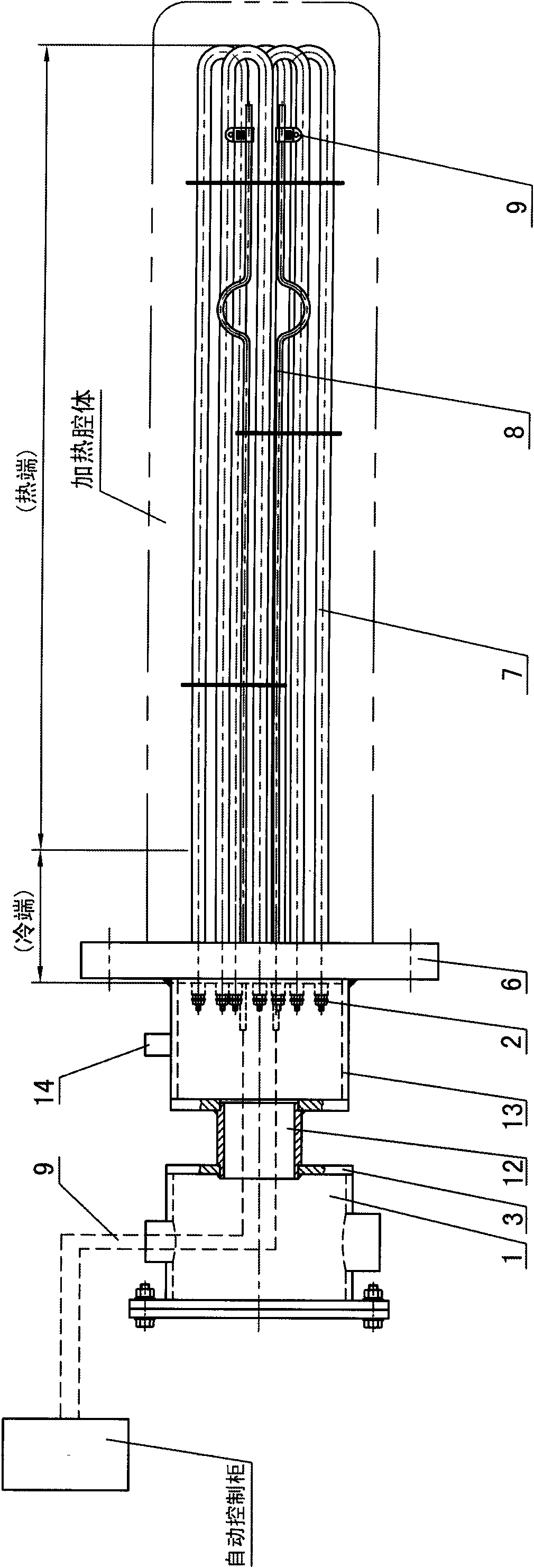

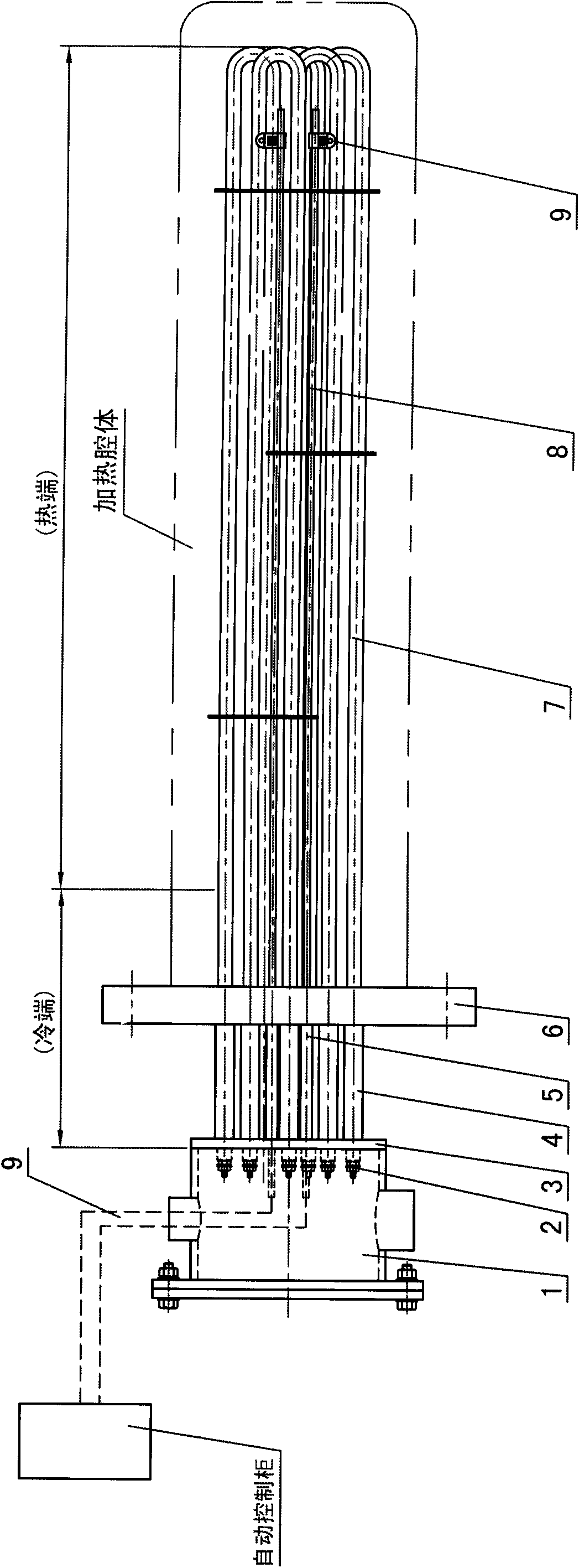

[0015] refer to figure 1 , figure 2 , image 3 , Figure 4 : The present invention is a strong safety and energy-saving explosion-proof electric heater, the nozzle of the electric heating tube 7 is welded on the flange plate 6, and the nozzle of the temperature measuring protection tube 11 of the temperature sensor 8 is welded on the flange plate 6 Weld the filled powder cylinder 13 on the end face of the flange plate 6; weld a deflation valve seat 14 on the circle of the filled powder cylinder; weld the pouring resin cylinder 12 on the end face of the filling powder cylinder; The tube plate 3 is welded on the outer circle of the end face of the cylinder; the explosion-proof wiring cavity 1 is welded on the end face circle of the tube plate.

[0016] Lead out the electric heating pipe wiring from each electric heating pipe terminal 2, into the powder-filling cylinder 13, then into the pouring resin cylinder 12, extend into the explosion-proof wiring cavity 1, and finally c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com