Electrode contact member of vacuum circuit breaker and process for production of the same

A vacuum circuit breaker and circuit breaker technology, which is applied to high-voltage air circuit breakers, electrical components, contacts, etc., can solve the problems of reduced service life, contamination, and low withstand voltage of vacuum circuit breakers, so as to prevent the reduction of withstand voltage, Effect of suppressing increase in contact resistance and improving breaking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

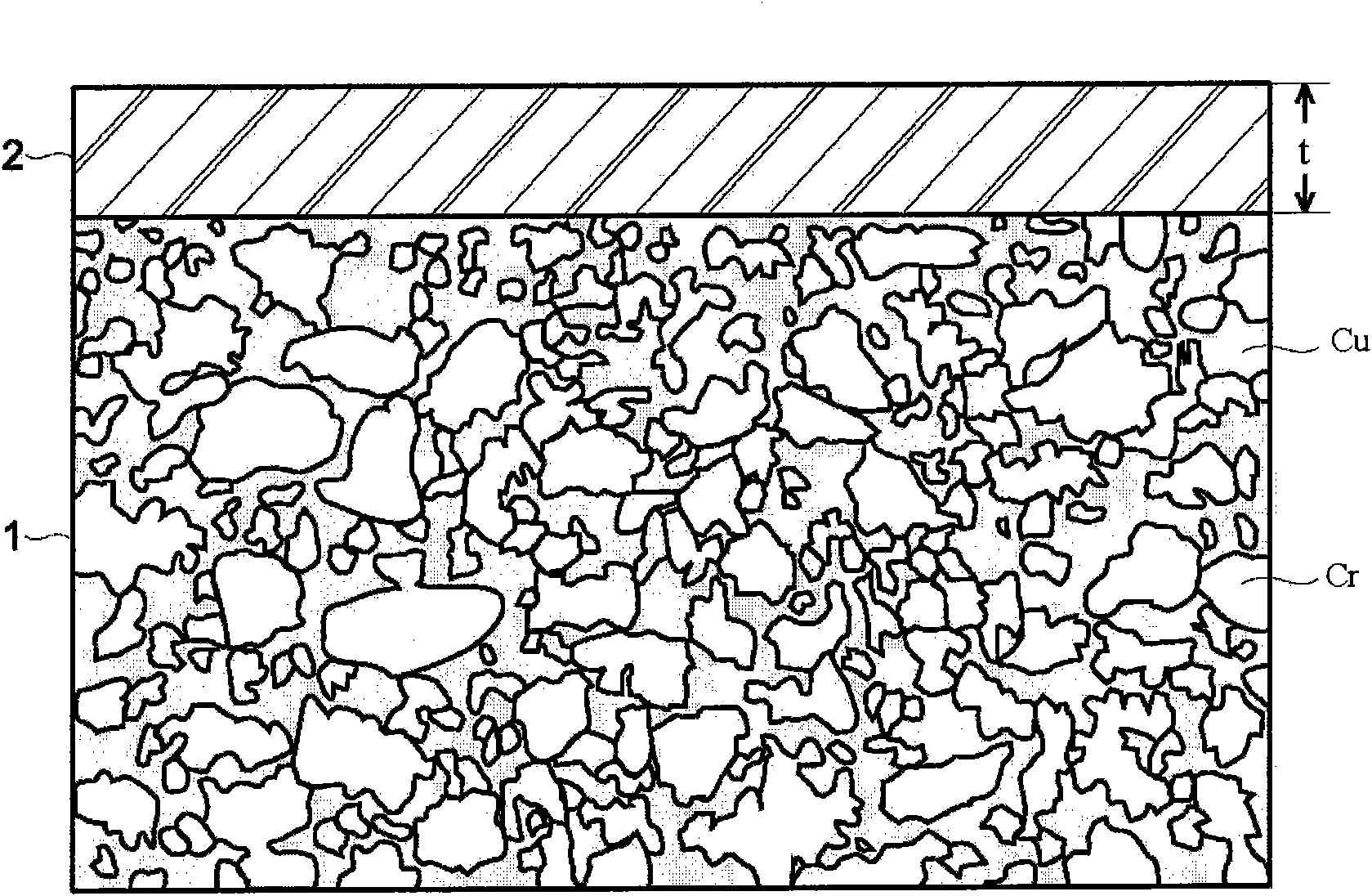

[0026] The electrode contact parts of the vacuum circuit breaker of the present invention are such as figure 1 As shown, the electrode contact part is formed using a two-layer structure as a Cu-Cr alloy base material 1 and a Cr finely dispersed layer 2. The Cu-Cr alloy base material 1 is a powdered Cu-Cr alloy base material in a predetermined ratio. Mixing, sintering in vacuum or non-oxygen gas atmosphere such as inert gas, and compressing the sintered Cu-Cr alloy base material to make the particles close at the same time, or the Cu-Cr alloy base material formed by vacuum melting a certain proportion of Cu and Cr.

[0027] For the Cu-Cr alloy base material 1, if the Cr content is less than 20% by weight, the improvement of the breaking performance cannot be satisfied, and it cannot be expected to prevent the drop in withstand voltage, and if the Cr content exceeds 60% by weight, there will be a The resistance becomes high and the conductivity decreases, or the material of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com