Foldable-expandable shape memory supporting pipe and preparation method thereof

A support tube and memory technology, which is applied in the field of shape memory support tube and its preparation, can solve the problems of large volume and heavy weight, and achieve the effects of strong support capacity, light weight and improved recovery force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

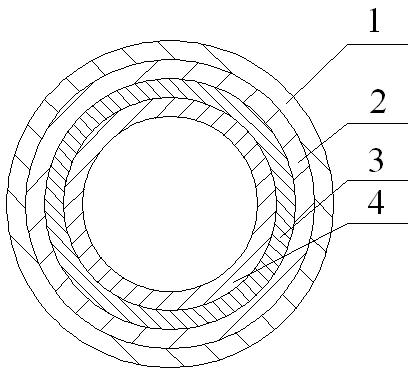

[0010] Embodiment 1: A foldable-expandable shape-memory support tube in this embodiment is composed of a polyimide liner 4 and an outer wall wrapped around the polyimide liner, wherein the polyimide liner is outside the polyimide liner. The outer wall is composed of prepreg layer 3, electric heating layer 2 and heat insulation layer 1 from inside to outside, prepreg layer 3 is made of shape memory composite material, electric heating layer 2 is made of two layers of polyimide film and It is composed of electric heating wires arranged in a serpentine shape between two layers of polyimide film. The heat insulation layer 1 is composed of polyimide film. After the shape memory support tube is unfolded, the shape is a hollow cylindrical tube. The two ends of the shaped tube are sealed with aluminum caps respectively, and the air pipe of the polyimide liner and the electric heating wire of the electric heating layer are led out from the aluminum cap on one side of the cylindrical sha...

specific Embodiment approach 2

[0012] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the prepreg layer 3 is made of a shape memory composite material, and the preparation method of the shape memory composite material is carried out according to the following steps: a. Take 70~90 parts of epoxy resin E-51, 10~30 parts of polypropylene glycol diglycidyl ether and 12~15 parts of 4,4'-diaminodiphenylmethane, in a temperature of 80℃~85℃ Stir for 5min~10min under the same conditions, and cool down to room temperature to obtain the shape memory resin glue; b. Arrange the fibers in an oven with a temperature of 70℃~80℃ for 0.8h~1.5h, and then press the fiber cloth and shape memory resin glue The mass ratio of the solution is 1:4~9, and the shape memory resin glue prepared in step a is evenly brushed on the fiber cloth in one direction, and then placed in an oven at a temperature of 80°C~85°C for 20min~25min , to obtain a prepreg; c. Heat up the prepreg obtained in step b to 80°C~85°C ...

specific Embodiment approach 3

[0014] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the preparation method of the shape memory composite material is carried out according to the following steps: a, weigh 80 parts of epoxy resin E-51, 20 according to the ratio of parts by mass 1 part of polypropylene glycol diglycidyl ether and 13 parts of 4,4'-diaminodiphenylmethane, stirred for 8 minutes at a temperature of 82 ° C, and cooled to room temperature to obtain a shape memory resin glue; b. Arrange the fibers at a temperature Treat in an oven at 75°C for 1.0 h, then apply the shape memory resin glue prepared in step a evenly on the fiber cloth in one direction according to the mass ratio of fiber cloth to shape memory resin glue of 1:6, Then put it in an oven with a temperature of 82°C for 23 minutes to obtain a prepreg; c, raise the temperature of the prepreg obtained in step b to 83°C and keep it for 3.2 hours, continue to raise the temperature to 153°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com