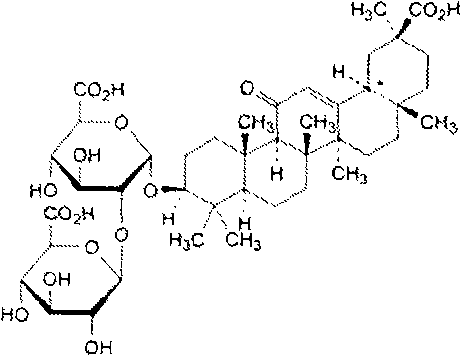

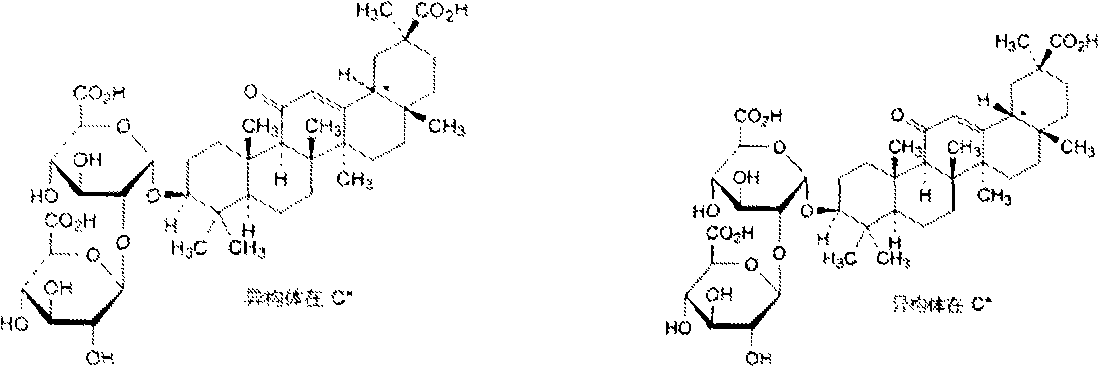

Preparation method of diammonium glycyrrhizinate salt capable of accurately controlling ammonium radical content

A technology of diammonium glycyrrhizinate and diammonium glycyrrhizinate, which is applied to the preparation of sugar derivatives, chemical instruments and methods, and color/spectral property measurement, can solve problems such as differences in configuration and composition, and achieve improved yields and reduced Effect of the crystallization step

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

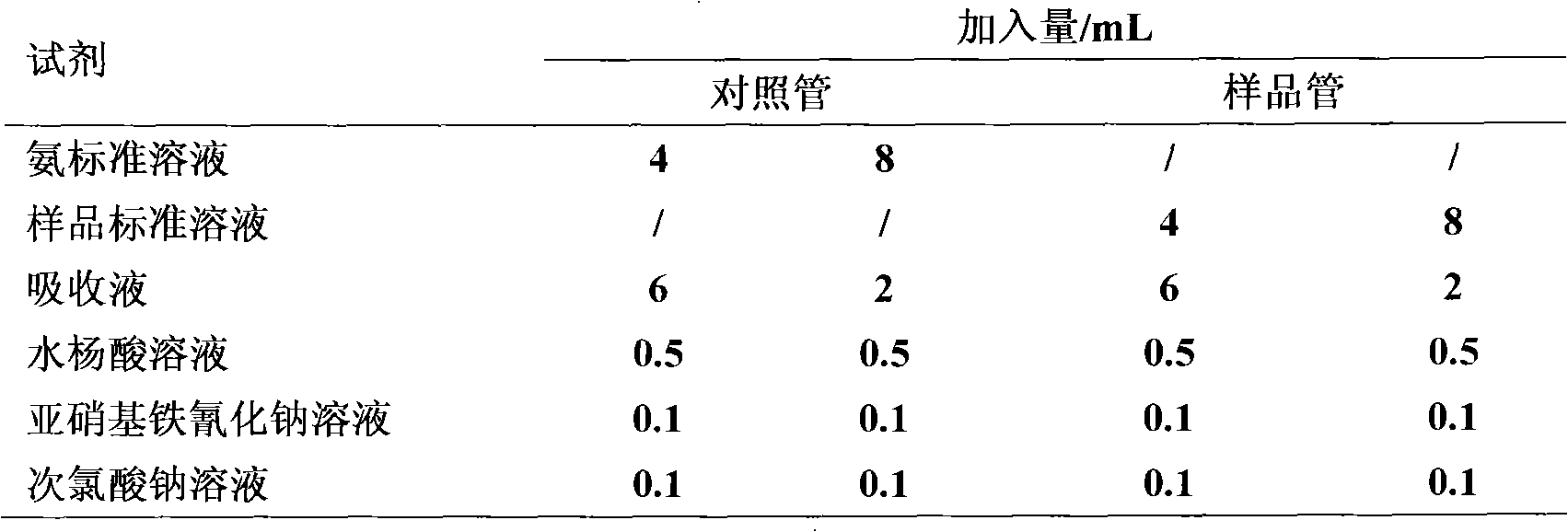

Method used

Image

Examples

Embodiment 1

[0060] Embodiment 1: Preparation of diammonium glycyrrhizinate by adopting known and satisfactory monoammonium glycyrrhizinate mainly in 18α configuration

[0061] (1) Take 50 g of monoammonium glycyrrhizinate, add 100 mL of water, heat and stir to dissolve, add about 11 mL of 6.8% ammonia water to adjust the pH value to 4.6.

[0062] (2) The above liquid medicine is added to a stainless steel plate, vacuum freeze-dried, vacuumized, the temperature of the product is controlled below -10°C for primary sublimation, the temperature is raised after the water is basically removed, and the temperature of the product is controlled below 40°C for secondary drying. The final product was obtained as off-white loose solid.

[0063] (3) The product yield is basically 100%.

[0064] (4) Test results of configuration and ammonium root content: The measured 18α configuration accounts for 76.4%, and the ammonium root content is 77.3%.

Embodiment 2

[0065] Embodiment 2: Preparation of diammonium glycyrrhizinate by adopting the monoammonium glycyrrhizinate mainly in 18α configuration known to meet the requirements

[0066] (1) Take 50 g of monoammonium glycyrrhizinate, add 100 mL of water, heat and stir to dissolve, add about 13 mL of 13.6% ammonia water to adjust the pH value to 6.0.

[0067] (2) The above liquid medicine is added to a stainless steel plate, vacuum freeze-dried, vacuumized, the temperature of the product is controlled below -10°C for primary sublimation, the temperature is raised after the water is basically removed, and the temperature of the product is controlled below 40°C for secondary drying. The final product was obtained as off-white loose solid.

[0068] (3) The product yield is basically 100%.

[0069] (4) Test results of configuration and ammonium root content: the measured 18α configuration accounts for 75.2%, and the ammonium root content is 106.7%.

Embodiment 3

[0070] Embodiment 3: Preparation of diammonium glycyrrhizinate by adopting known and satisfactory monoammonium glycyrrhizinate mainly in 18α configuration

[0071] (1) Take 1000 g of monoammonium glycyrrhizinate, add 2000 mL of water, heat and stir to dissolve, add about 260 mL of 6.8% ammonia water to adjust the pH value to 4.8.

[0072] (2) The above liquid medicine is added to a stainless steel plate, vacuum freeze-dried, vacuumized, the temperature of the product is controlled below -10°C for primary sublimation, the temperature is raised after the water is basically removed, and the temperature of the product is controlled below 40°C for secondary drying. The final product was obtained as off-white loose solid.

[0073] (3) The product yield is basically 100%.

[0074] (4) Test results of configuration and ammonium root content: The measured 18α configuration accounts for 76.3%, and the ammonium root content is 88.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com