Method for cooling metal band and installation for implementing said method

A technology of metal strips and strips, which can be used in household refrigeration equipment, furnace cooling, lighting and heating equipment, etc., and can solve problems such as cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

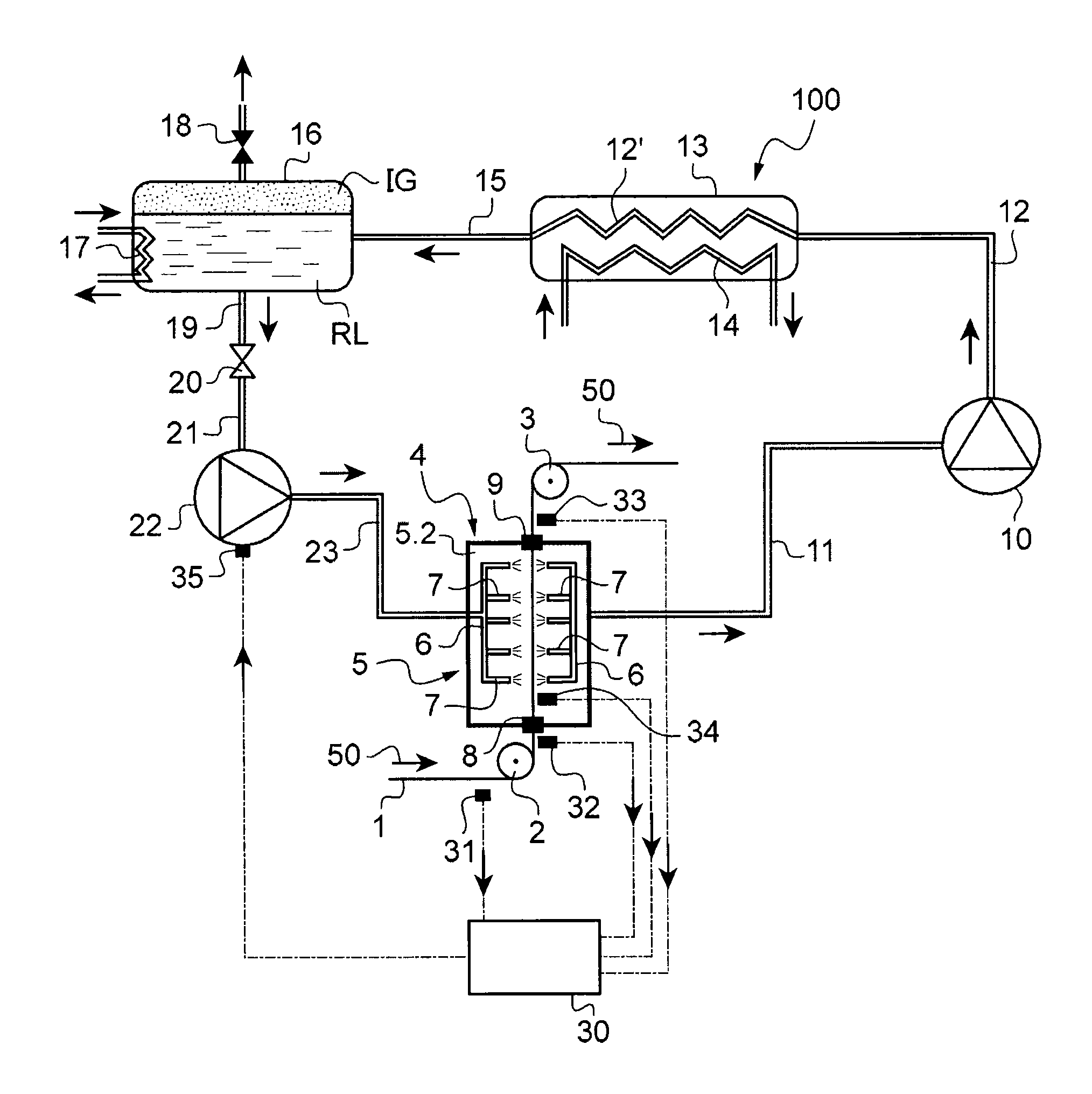

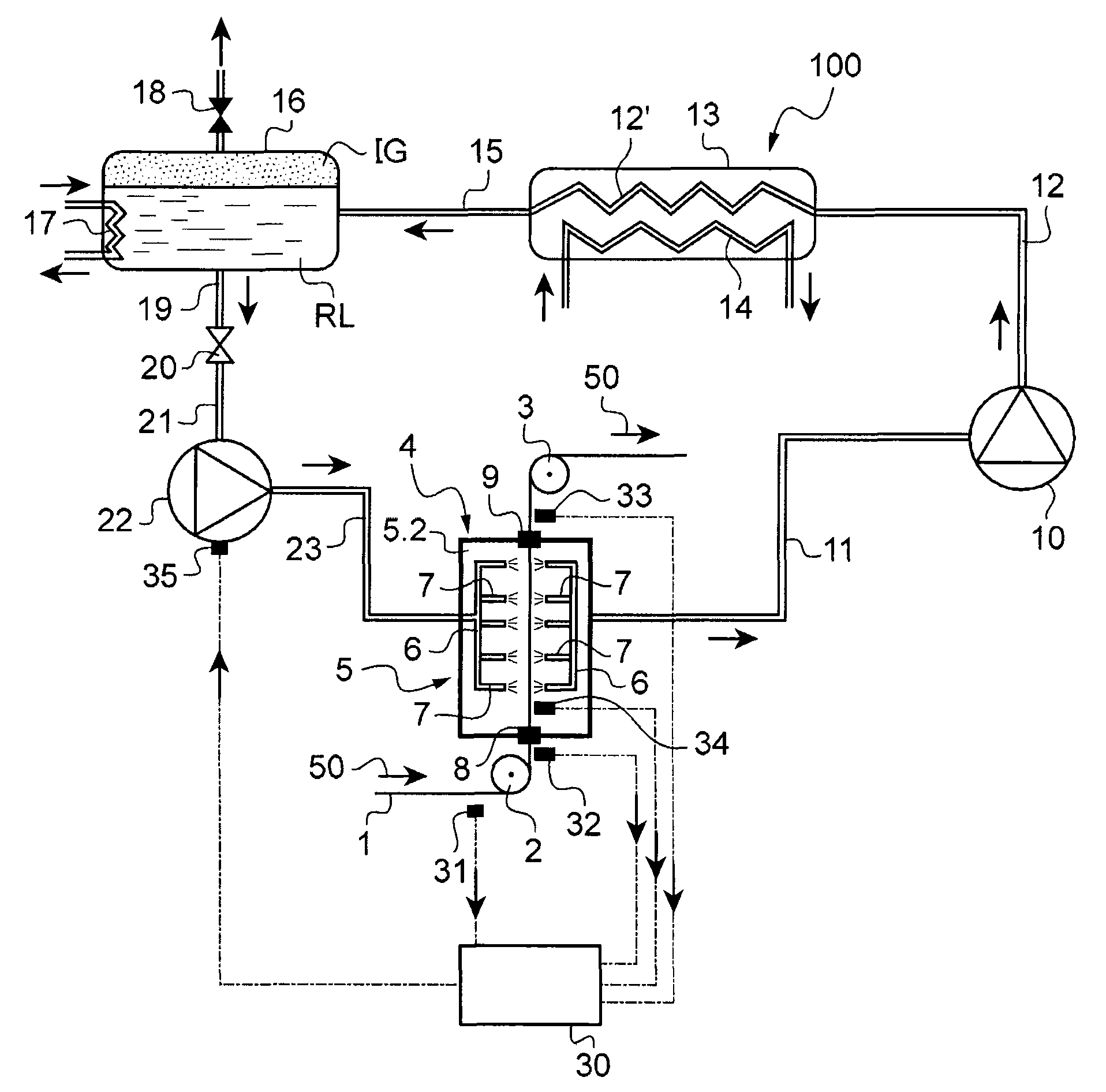

[0034] The only figure is a schematic diagram showing a device 100 for carrying out the cooling method according to the invention. The metal strip 1 moves through a cooling section 4 in a continuous heat treatment line, which may be an annealing line or a line for applying a metallic or organic coating.

[0035] According to the background art, the line along which the strip 1 passes is defined by bottom deflecting rollers 2 and top deflecting rollers 3 on each side of the cooling section 4 , the direction of movement of the metal strip 1 being indicated by arrow 50 .

[0036] The cooling section 4 comprises a cooling box 5 through which the metal strip 1 passes for cooling. The cooling box 5 is closed and the strip passes in a sealed manner through inlet and outlet airlocks 8 and 9, both shown schematically. They may consist of a flap system optionally cooperating with carrying rollers, which are well known in the field of continuous processing lines. By means of the inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com