Method and device for mounting piezoelectric wafer used for structure health monitoring

A piezoelectric chip, health monitoring technology, applied in the direction of measuring devices, machine/structural component testing, instruments, etc., can solve the problem of difficult to find and replace, unsuitable thin shell structure, bonding interface and piezoelectric chip life-span structure Life expectancy and other issues to achieve the effect of improving monitoring and diagnosis efficiency, realizing structural health monitoring, and ensuring repeatability and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

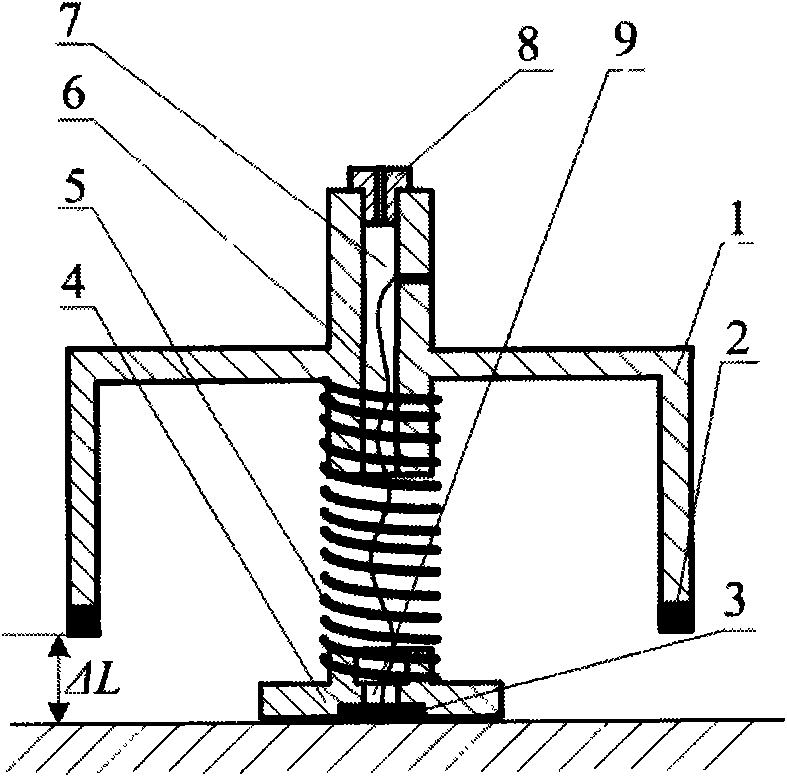

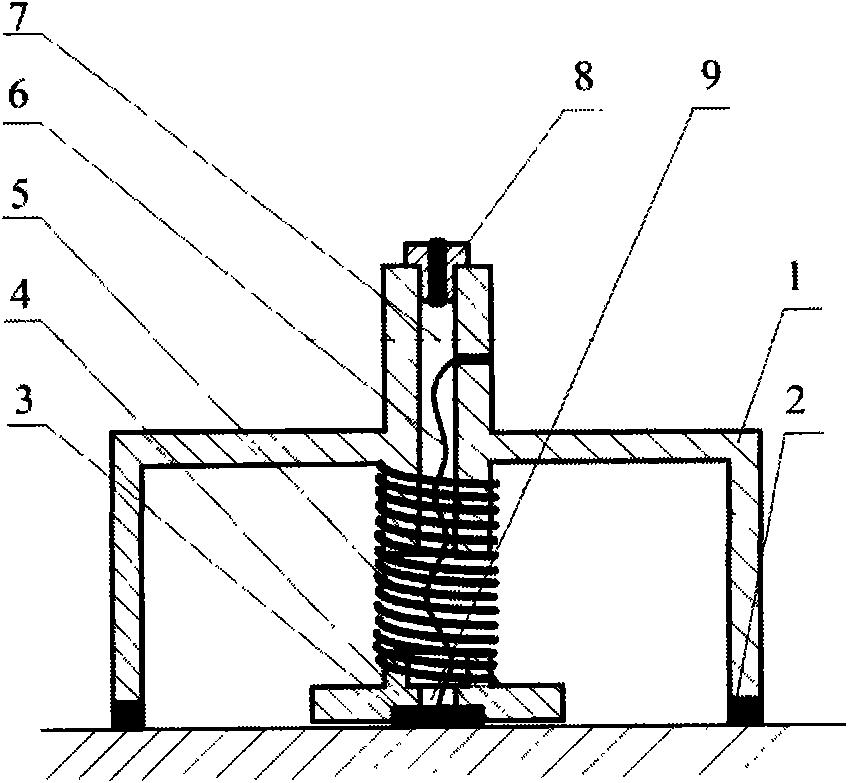

[0042] Embodiment 1, a method and device for installing a piezoelectric wafer for structural health monitoring.

[0043] Such as figure 1 As shown, it is composed of concave cavity hard body 1, concave cavity adsorption software 2, piezoelectric chip 3, piezoelectric chip seat 4, and spring 5; the inner and outer surfaces of concave cavity hard body 1 and piezoelectric chip seat 4 The connection springs are in the form of hollow bosses, and the springs are sheathed on the bosses; the centers of the bosses are respectively provided with an air hole 7 and a connecting wire through hole 9, and the air hole 7 is equipped with an air nozzle 8. The lead-through part is sealed with polyurethane material.

[0044] The piezoelectric wafer seat 4 is provided with a groove for placing the piezoelectric wafer, and its depth is smaller than the thickness of the piezoelectric wafer.

[0045] The opening surface and the upper surface of the concave cavity are circular, with a radius of 1.7...

Embodiment 2

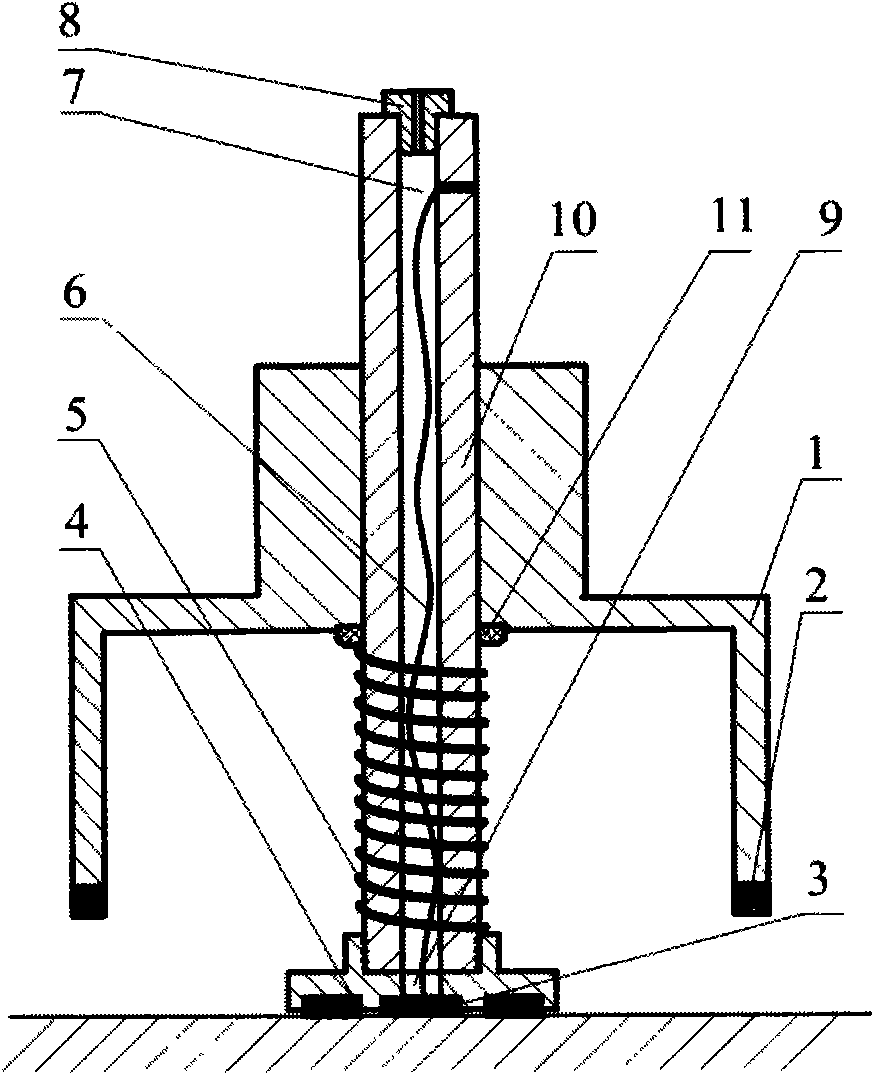

[0048] Example 2, a device with hollow guide rods for mounting piezoelectric wafers for structural health monitoring.

[0049] Such as image 3 , Figure 4 As shown, a hollow guide rod 10 stretching out from the concave cavity is provided between the piezoelectric wafer base 4 and the concave cavity hard body 1, and the hollow guide rod 10 is fixedly connected with the piezoelectric wafer base 4, and is connected with the concave cavity. A sealing ring 11 is installed between the cavity hard bodies 1, the concave cavity hard body 1 and the sealing ring 11 can move along the hollow guide rod 10, the spring 5 is set on the hollow guide rod 10, and the hollow guide rod extends out of the concave cavity The hollow part is air hole 7, and air nozzle 8 is housed.

[0050] The structure of the piezoelectric wafer seat 4 is as Figure 10 , Figure 11 As shown, one side is arranged with 5 grooves for placing piezoelectric wafers, wherein a circular groove 22 is at the center, and 4...

Embodiment 3

[0053] Embodiment 3, the piezoelectric chip installation method and its device using a closed piston.

[0054] Such as Figure 5 , Figure 6 , Figure 7 Shown, the device of installing piezoelectric chip is as embodiment 1, but the piston barrel 13 of airtight piston is housed on the concave cavity hard outer surface, seals with gasket 12, and air hole 7 is communicated with piston. The structure of the piezoelectric wafer seat is the same as in Embodiment 2.

[0055] The connecting rod of piston 14 passes through the central through hole of piston handle 15, then fixes with nut 16, can make piston handle rotate flexibly. The piston handle 15 is placed in the two U-shaped grooves 17 on the piston barrel 13 before being pulled, and the piston 14 is pulled outward until the piston handle moves out of the U-shaped groove, and then the piston handle 15 is turned so that it is stuck on the edge of the piston barrel 13. The position of the piston can be fixed, so that the piston...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com