Master and slave control method based on high-voltage big-power transducer

A control method and high-power technology, which is applied in the field of inverter control, can solve the problems of uneven driving of the main motor and the slave motor, and achieve the effects of saving costs, avoiding high-speed and accurate transmission, and simple connection structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

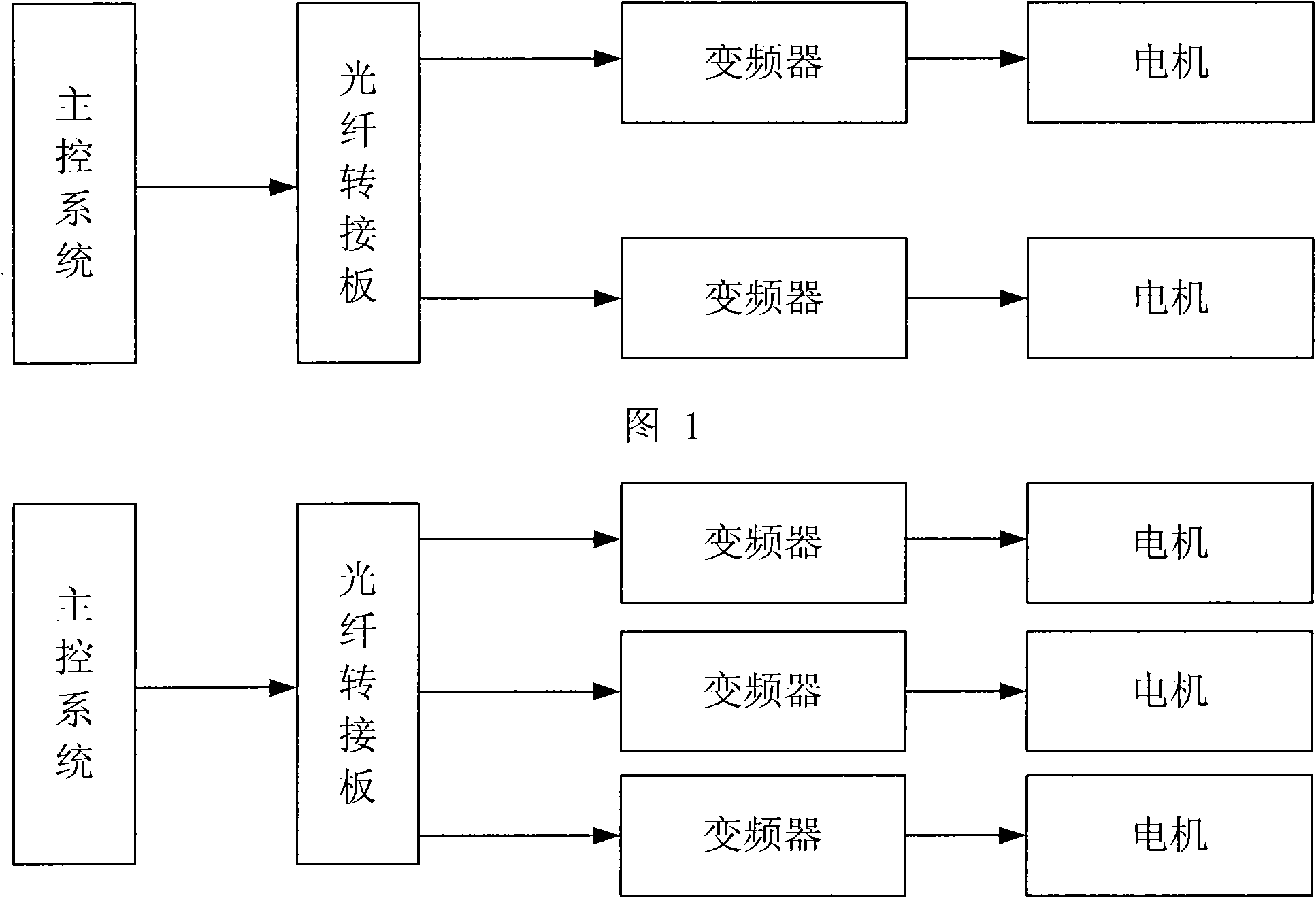

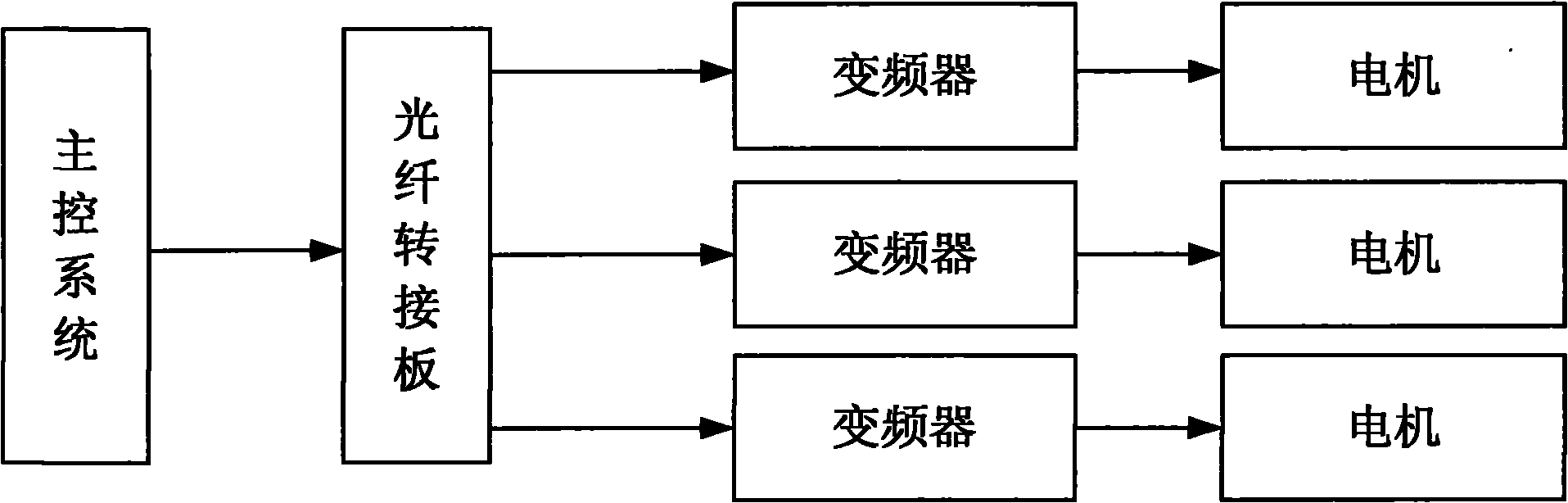

[0019] Like the traditional master-slave control equipment, the present invention is composed of a master control system, N cascaded high-voltage and high-power frequency converters, and motors corresponding in number to the high-voltage and high-power frequency converters. Wherein, the value of N is selected according to actual needs, and its value is N≥2.

[0020] In order to better realize the present invention, the present invention also adds a set of optical fiber adapter boards to the traditional equipment. At the same time, in order to ensure the accurate transmission of various signals, when connecting, the main control system passes through the optical fiber and the optical fiber adapter board. At the same time, each high-voltage and high-power inverter is also connected to the fiber optic adapter board through optical fibers. Correspondingly, each high-voltage and high-power inverter is connected to a motor so as to provide driving voltage for the motor.

[0021] Wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com