A kind of preparation method of near-spherical mullite-coated particles

A mullite and near-spherical technology, applied in chemical instruments and methods, fibrous fillers, dyed organosilicon compound treatment, etc., can solve problems that have not been seen before, achieve good thermal stability, simple synthesis process, and environmental friendliness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] A preparation method for nearly spherical mullite-coated particles, comprising:

[0043] S1) dispersing the particles to be wrapped in the solution to obtain a dispersion;

[0044] S2) Amorphous package, including:

[0045] S2-a) Add a silicon source to the dispersion, stir to hydrolyze the silicon source and form amorphous SiO on the surface of the particles to be coated 2 ·xH 2 O cladding layer;

[0046] S2-b) Further add an aluminum source to the dispersion, stir to hydrolyze the aluminum source and form amorphous Al on the surface of the particle to be wrapped 2 o 3 ·xH 2 O cladding; or

[0047] S2-1) Add an aluminum source to the dispersion, stir to hydrolyze the aluminum source and form amorphous Al on the surface of the particle to be wrapped 2 o 3 ·xH 2 O cladding layer;

[0048] S2-2) Further add a silicon source to the dispersion, stir to hydrolyze the silicon source and form amorphous SiO on the surface of the particles to be wrapped 2 ·xH 2 O cla...

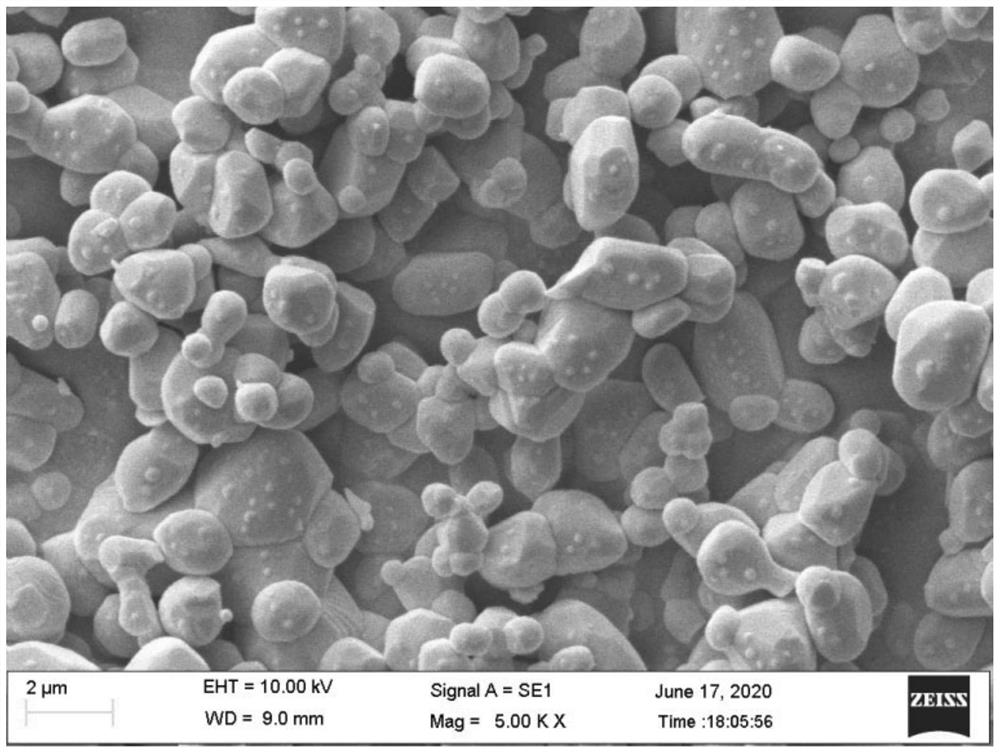

Embodiment 1

[0066] Embodiment 1: Preparation of mullite-coated cadmium sulfoselenide pigment

[0067] 1) Disperse cadmium sulfur selenide toner with a particle size of 80-10 nanometers in a mixed solution of ethanol and water, adjust the pH to 9 with ammonia water, stir magnetically at room temperature, and take ethyl orthosilicate at 0.5ml / min Drop into the mixed solution, and continue to stir for 2h after the drop to form amorphous SiO 2 .xH 2 O-coated cadmium sulfoselenide, wherein the volume ratio of ethyl orthosilicate, ethanol and water is 1:10:3, and the molar ratio of Cd:Si is 1:3;

[0068] 2) Dissolve aluminum isopropoxide in water to prepare a solution with a concentration of 0.3mol / L, drop it into the solution in step 2 at 0.5ml / min, and continue stirring for 2 hours after dropping to form amorphous Al 2 o 3 .xH 2 O cladding layer, add mineralizer lithium fluoride and stir for 1h to obtain mixed slurry, wherein Si:Al:F molar ratio is 1:3:0.006;

[0069] 3) Take samarium ni...

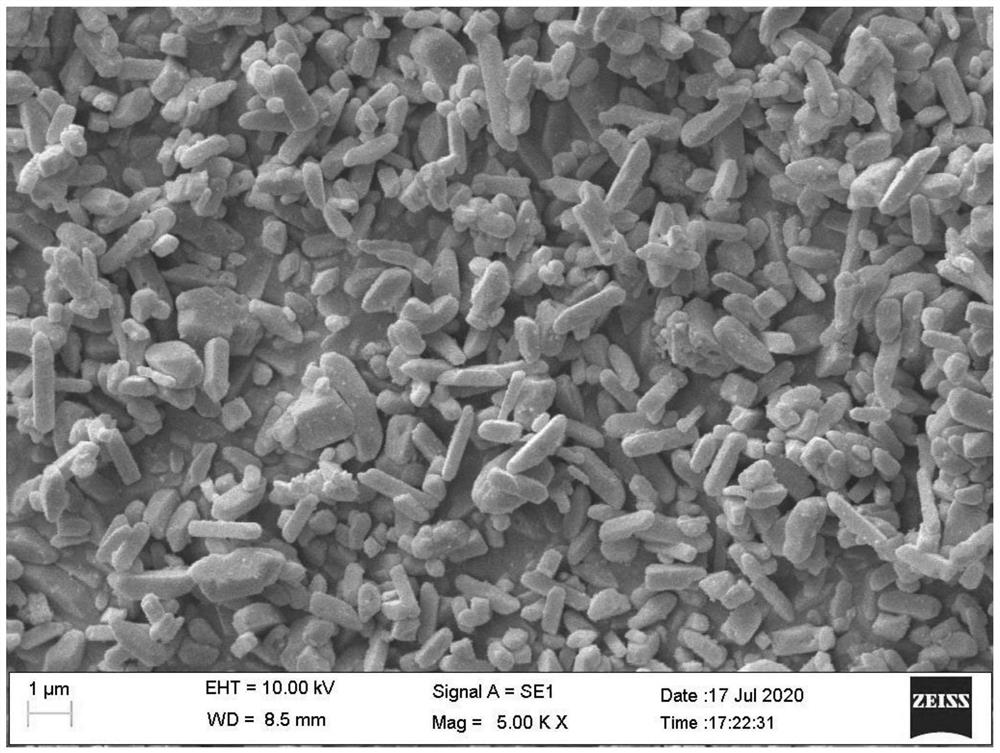

Embodiment 2

[0072] Embodiment 2: Preparation of mullite-coated cadmium sulfoselenide pigment

[0073] 1) Disperse cadmium sulfur selenide toner with a particle size of 10-60 nanometers in a mixed solution of ethanol and water, adjust the pH to 8.5 with ammonia water, stir magnetically at room temperature, and take ethyl orthosilicate at 0.2ml / min Drop into the mixed solution, and continue to stir for 4h after the drop to form amorphous SiO 2 .xH 2 O-coated cadmium sulfoselenide, wherein the volume ratio of ethyl orthosilicate, ethanol and water is 1:10:1, and the molar ratio of Cd:Si is 1:4;

[0074] 2) Dissolve aluminum isopropoxide in water to prepare a solution with a concentration of 0.1mol / L, drop it into the solution in step 2 at 0.2ml / min, and continue stirring for 4 hours after dropping to form amorphous Al 2 o 3 .xH 2 O coating layer, add mineralizer lithium fluoride and stir for 2h to obtain mixed slurry, wherein Si:Al:F molar ratio is 1:3:0.008;

[0075] 3) Take lanthanum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com