Preparation method of nearly spherical mullite coated particles

A mullite, near-spherical technology, applied in chemical instruments and methods, inorganic pigment treatment, dyed organosilicon compound treatment, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] A preparation method for nearly spherical mullite-coated particles, comprising:

[0043] S1) dispersing the particles to be wrapped in the solution to obtain a dispersion;

[0044] S2) Amorphous package, including:

[0045] S2-a) Add a silicon source to the dispersion, stir to hydrolyze the silicon source and form amorphous SiO on the surface of the particles to be coated 2 ·xH 2 O cladding layer;

[0046] S2-b) Further add an aluminum source to the dispersion, stir to hydrolyze the aluminum source and form amorphous Al on the surface of the particle to be wrapped 2 o 3 ·xH 2 O cladding; or

[0047] S2-1) Add an aluminum source to the dispersion, stir to hydrolyze the aluminum source and form amorphous Al on the surface of the particle to be wrapped 2 o 3 ·xH 2 O cladding layer;

[0048] S2-2) Further add a silicon source to the dispersion, stir to hydrolyze the silicon source and form amorphous SiO on the surface of the particles to be wrapped 2 ·xH 2 O cla...

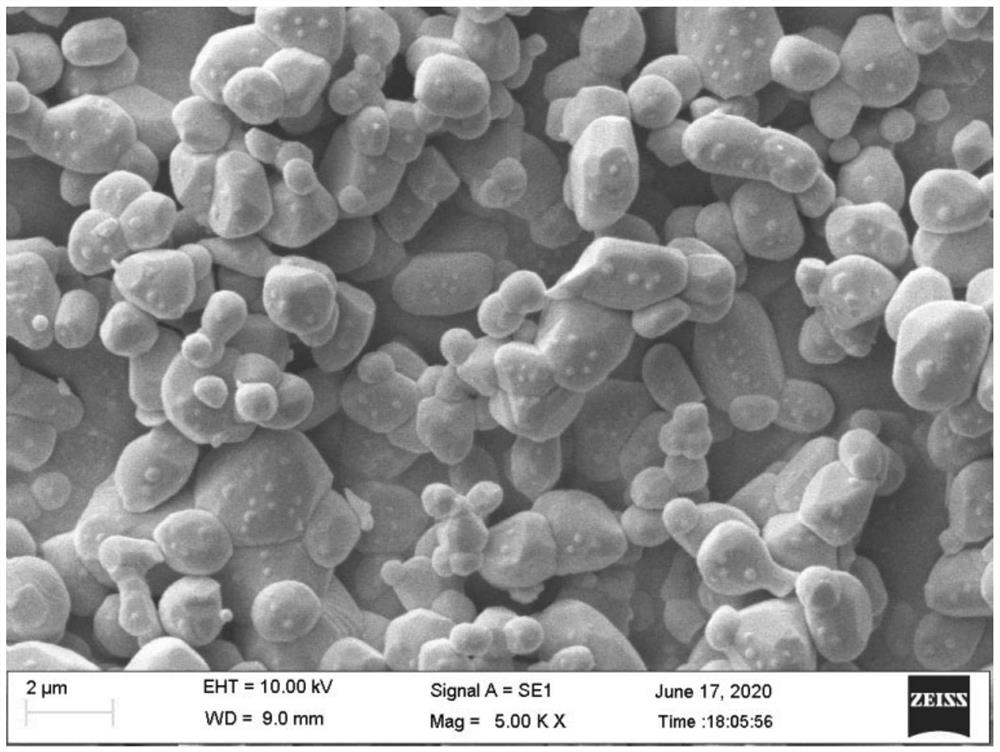

Embodiment 1

[0066] Embodiment 1: Preparation of mullite-coated cadmium sulfoselenide pigment

[0067] 1) Disperse cadmium sulfur selenide toner with a particle size of 80-10 nanometers in a mixed solution of ethanol and water, adjust the pH to 9 with ammonia water, stir magnetically at room temperature, and take ethyl orthosilicate at 0.5ml / min Drop into the mixed solution, and continue to stir for 2h after the drop to form amorphous SiO 2 .xH 2 O-coated cadmium sulfoselenide, wherein the volume ratio of ethyl orthosilicate, ethanol and water is 1:10:3, and the molar ratio of Cd:Si is 1:3;

[0068] 2) Dissolve aluminum isopropoxide in water to prepare a solution with a concentration of 0.3mol / L, drop it into the solution in step 2 at 0.5ml / min, and continue stirring for 2 hours after dropping to form amorphous Al 2 o 3 .xH 2 O cladding layer, add mineralizer lithium fluoride and stir for 1h to obtain mixed slurry, wherein Si:Al:F molar ratio is 1:3:0.006;

[0069] 3) Take samarium ni...

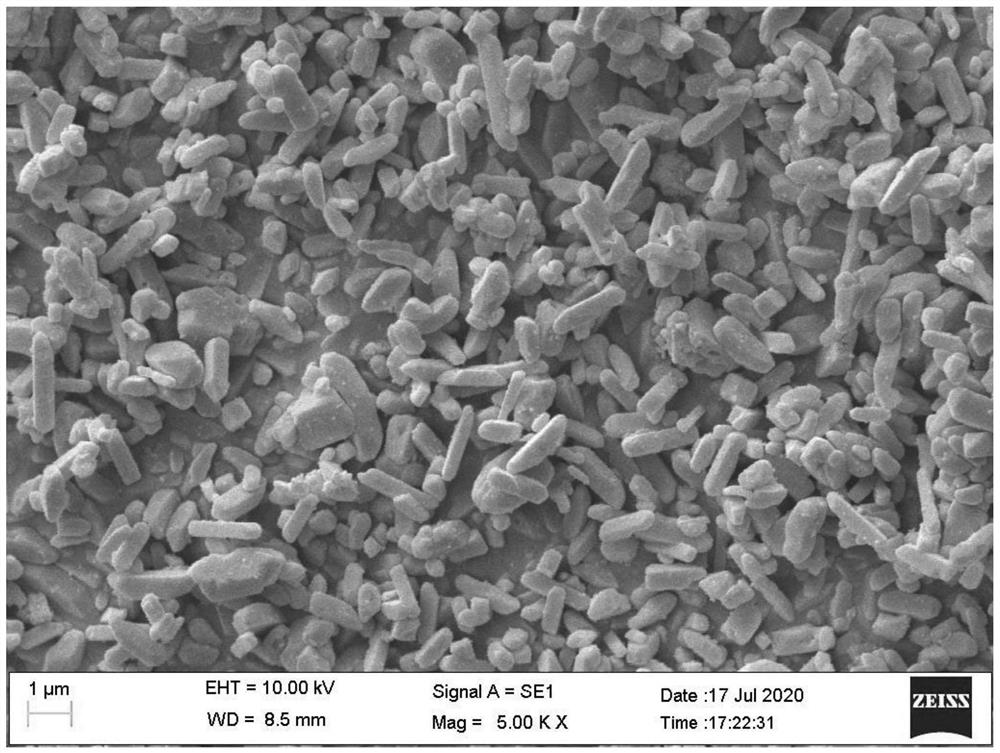

Embodiment 2

[0072] Embodiment 2: Preparation of mullite-coated cadmium sulfoselenide pigment

[0073] 1) Disperse cadmium sulfur selenide toner with a particle size of 10-60 nanometers in a mixed solution of ethanol and water, adjust the pH to 8.5 with ammonia water, stir magnetically at room temperature, and take ethyl orthosilicate at 0.2ml / min Drop into the mixed solution, and continue to stir for 4h after the drop to form amorphous SiO 2 .xH 2 O-coated cadmium sulfoselenide, wherein the volume ratio of ethyl orthosilicate, ethanol and water is 1:10:1, and the molar ratio of Cd:Si is 1:4;

[0074] 2) Dissolve aluminum isopropoxide in water to prepare a solution with a concentration of 0.1mol / L, drop it into the solution in step 2 at 0.2ml / min, and continue stirring for 4 hours after dropping to form amorphous Al 2 o 3 .xH 2 O coating layer, add mineralizer lithium fluoride and stir for 2h to obtain mixed slurry, wherein Si:Al:F molar ratio is 1:3:0.008;

[0075] 3) Take lanthanum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com