Multifunctional integral anti-buckling wall column structure

An anti-buckling and multi-functional technology, applied in the direction of columns, walls, pier columns, etc., can solve the problems of increasing construction procedures, construction difficulties, single function, etc., achieve good restraint performance, reduce construction costs, and save construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

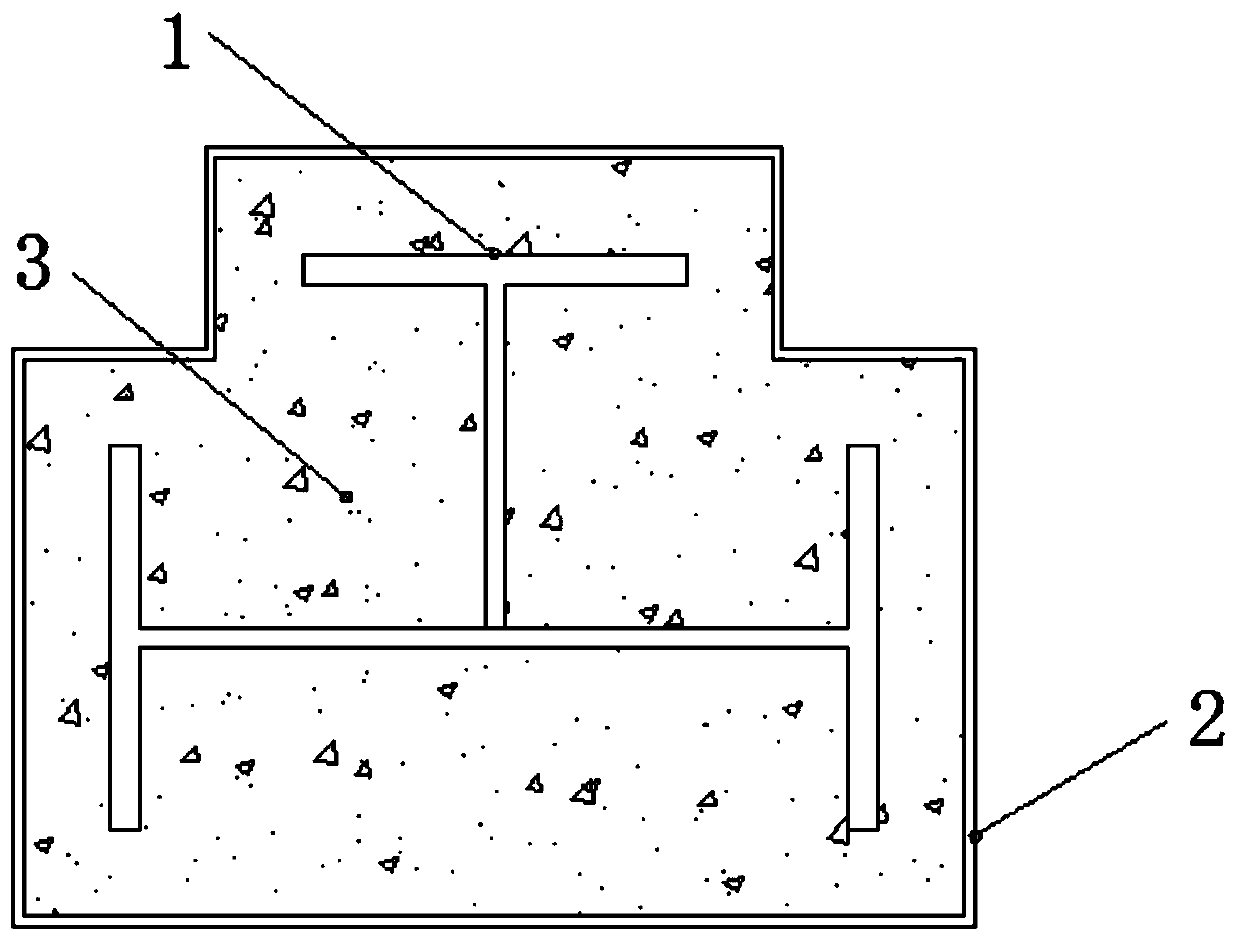

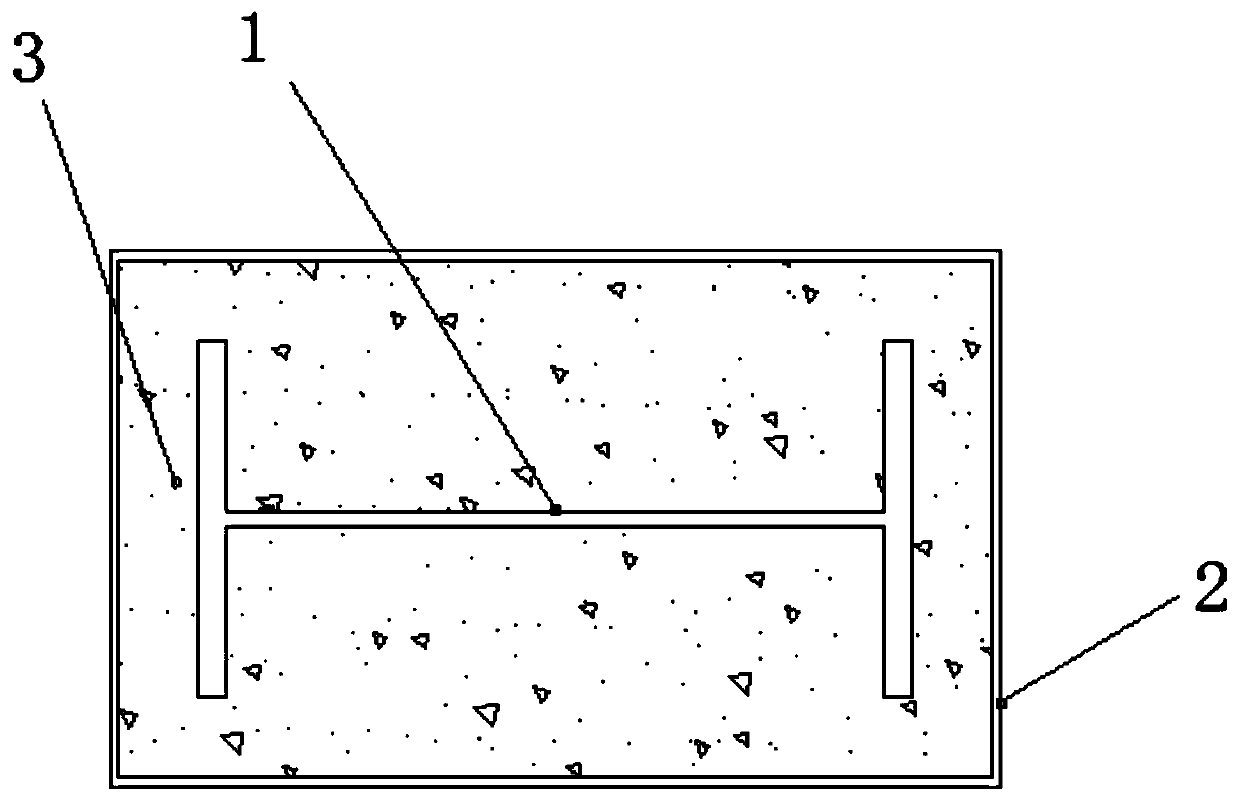

[0027] Such as figure 1 A multi-functional integrated anti-buckling wall column structure shown includes buckling-resistant components 1 , fiber-reinforced cladding wood substrates 2 and filling materials 3 . The fiber-reinforced cladding wood base plate forms a closed peripheral structure, the anti-buckling component is placed in the closed peripheral structure, and the filling material is poured in the gap between the fiber-reinforced cladding wood base plate and the buckling-resistant component by pouring. Specifically, the filling material may be concrete, mortar or other cement-based materials; the anti-buckling member may be steel or other alloy materials.

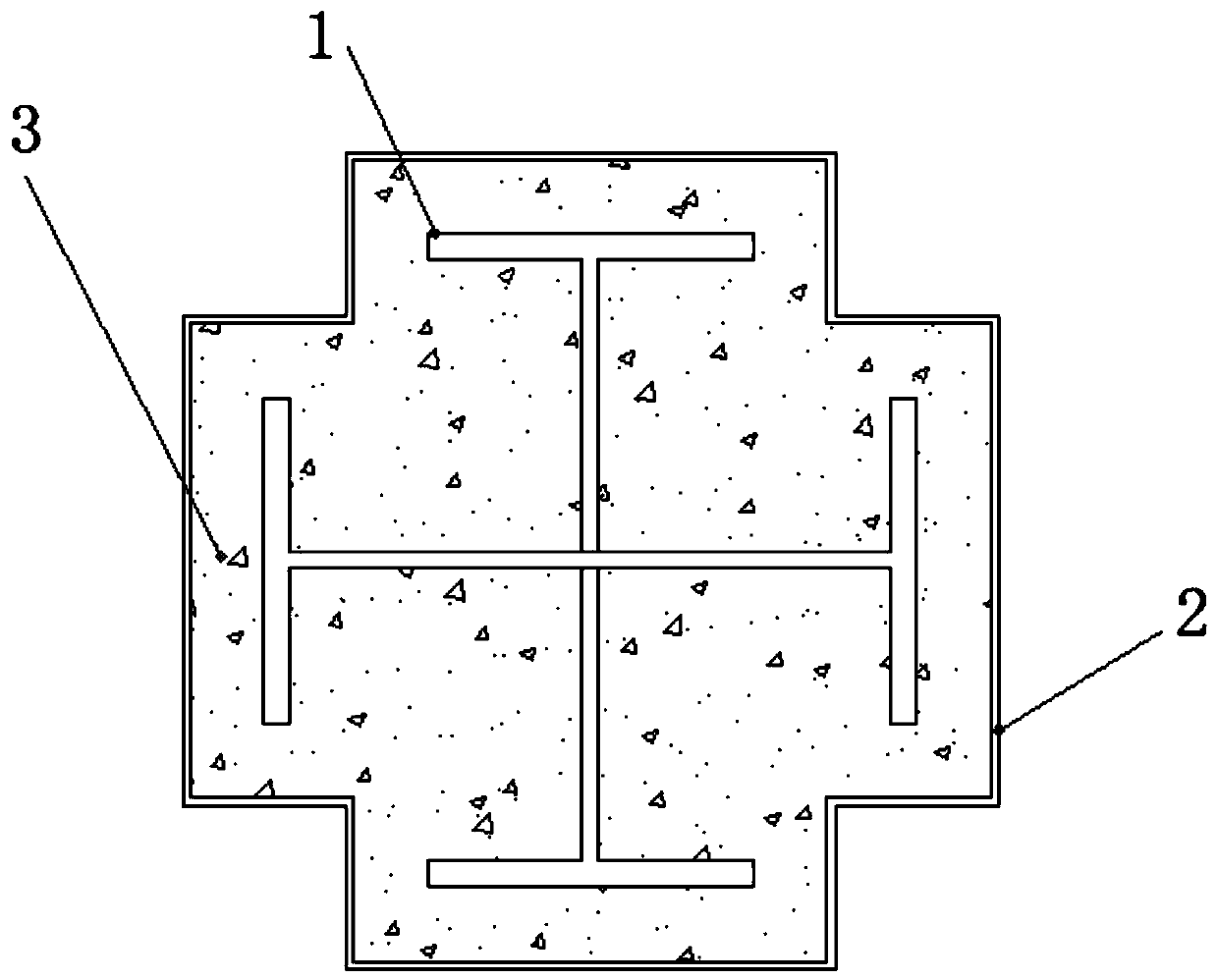

[0028] Generally, the anti-buckling member is made of steel, and when the steel is used, it can be I-beam, I-beam composite section, square steel pipe, round steel pipe, steel pipe bundle, steel pipe concrete, etc. Such as figure 1 As shown, the anti-buckling member can be T-shaped; such as figure 2 As shown, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com