Anti-noise jamming high-side drive circuit

A high-end drive and anti-noise technology, applied to circuits, electric light sources, inductors, etc., can solve the problems of destroying the normal operation of high-end circuits, false triggering of high-end circuits, and large common-mode noise, so as to shorten the conduction time and reduce power consumption. Power consumption, the effect of saving chip area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

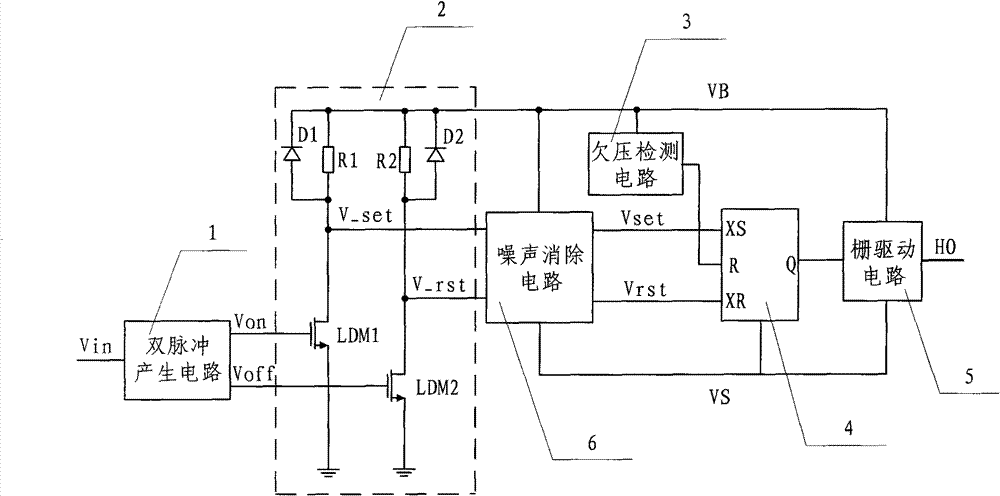

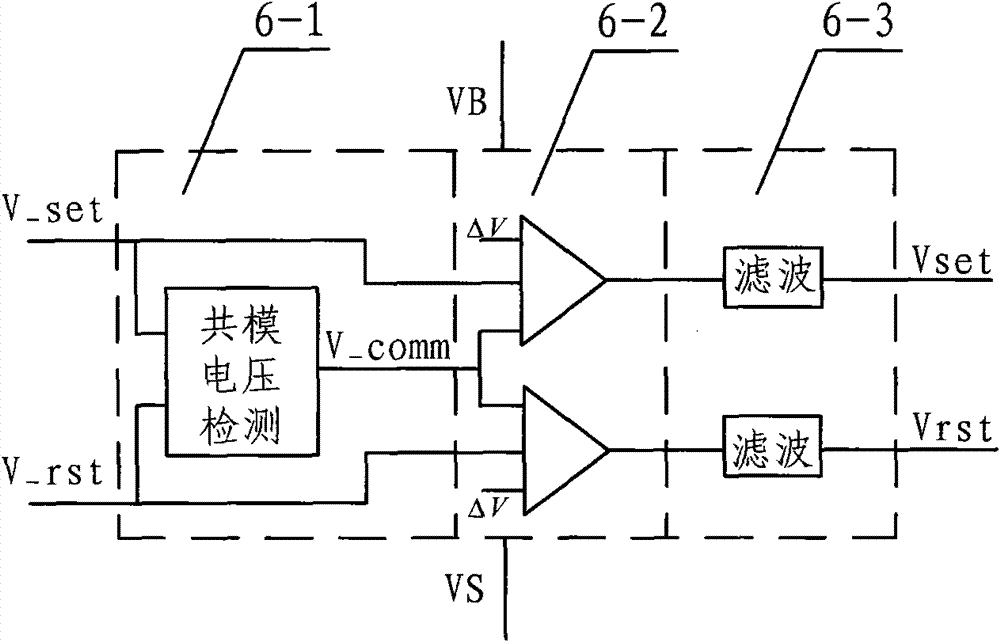

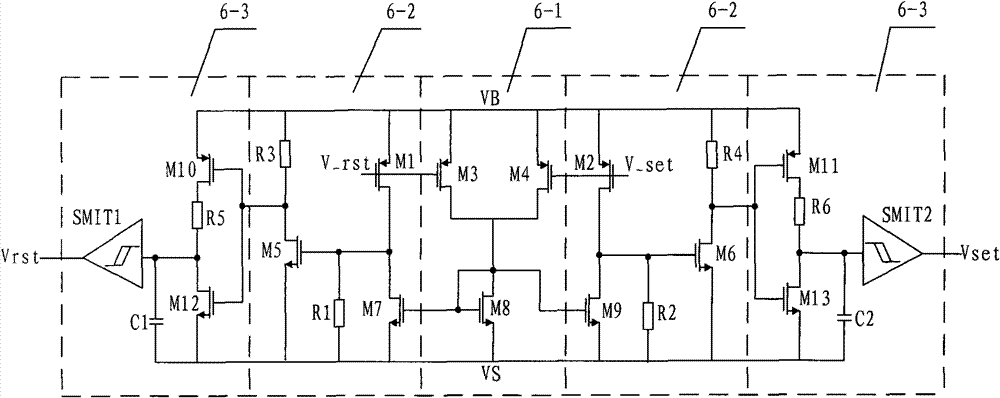

[0021] Such as figure 1 and figure 2As shown, the anti-noise interference high-end drive circuit of the present invention includes a floating power supply, a double pulse generation circuit 1, a high-voltage level shift circuit 2, an undervoltage detection circuit 3, an RS flip-flop circuit 4 and a gate drive circuit 5 ; The two input ends of the high-voltage level shift circuit 2 are respectively connected to the two output ends of the double-pulse generating circuit 1 and the two-way signals output by the double-pulse generating circuit 1 are respectively converted into high-voltage codirectional control signals V_set and V_rst output; It is characterized in that: also comprises noise elimination circuit 6, and described noise elimination circuit 6 is comprised of common mode voltage detection circuit 6-1 and the common mode noise elimination circuit 6-1 that joins with common mode voltage detection circuit 6-1 2; the two input terminals of the noise elimination circuit 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com