Solar frying device

A technology of solar energy and heat collectors, applied in the field of food heating equipment, can solve problems such as not easy to carry, inconvenient to use, and paraboloids are easily affected by dust and wind

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

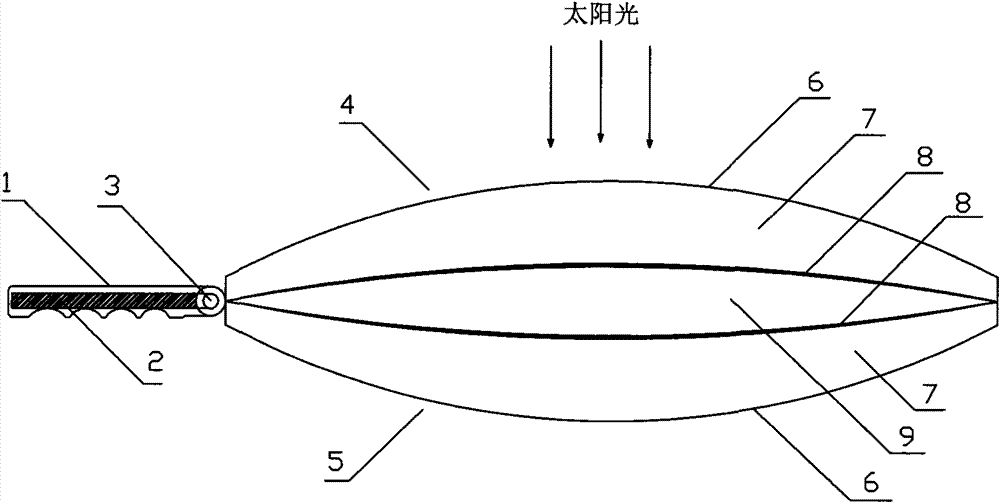

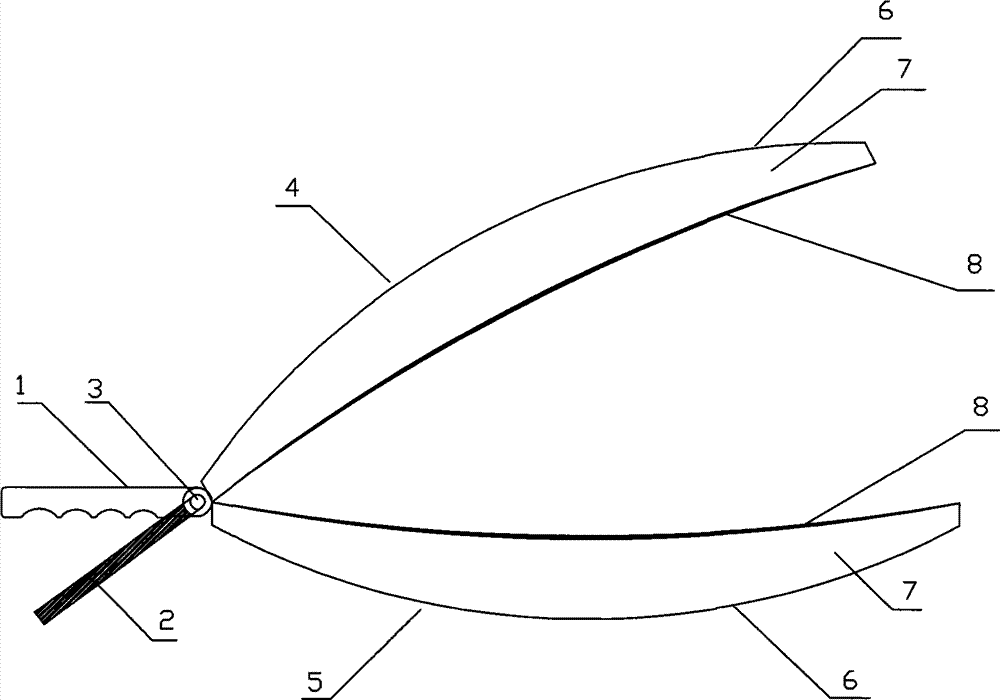

[0011] Such as figure 1 , figure 2 , The upper cover 4 and the lower cover 5 are both composed of solar vacuum glass heat collectors, and the upper cover 4 and the lower cover 5 are back-buckled together in a symmetrical dish shape, and the edges of the upper cover 4 and the lower cover 5 are tightly combined with high temperature silicone rubber pads , The high-temperature silicone rubber at the edge only plays a role of sealing and buffering. The upper cover 4 and the lower cover 5 are both thick in the middle and thin in the edge. The space formed by the two inner concave surfaces 8 is used to hold food, that is, food Space 9, the outer convex surface 6 of the upper cover 4 and the lower cover 5 are made of transparent glass, the inner concave surface 8 is made of stainless steel, the middle interlayer formed by the outer convex surface 6 and the inner concave surface 8 is a vacuum 7, the upper cover 4 and The vacuum surface of the inner concave surface 8 of the lower cover ...

Embodiment 2

[0013] Based on the first embodiment, after the upper cover 4 and the lower cover 5 are back-buckled into one body, the handle end is replaced with a belt pulley 15. There are bearings 14 at both ends of the rotation center line AA1 of the handle, and both ends are embedded in the bracket 10. , Under the action of the motor 12, the upper cover 4 and the lower cover 5 are continuously exchanged up and down through the belt 13, that is, rotate around AA1, and play the role of "bumping the spoon" during the cooking process. The energy of the motor 12 comes from the solar panel 11. The main shaft of the motor 12 can also be directly connected to the handle to directly drive the upper and lower covers to flip, or the motor 12 can be replaced with an eccentric motor to directly drive the upper and lower covers to vibrate left and right or up and down, which can also play a role of "flipping the spoon".

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com