Application of activated carbon modified material and application in removing arsenic from water

A technology of granular activated carbon and adsorption materials, which is applied in the direction of water pollutants, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., and can solve the problems of food safety and restoration efficiency that are greatly affected by environmental and climatic conditions. No high-level problems, low cost of use, simple preparation process, and good use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] An adsorption material for removing arsenic from water, the components by weight are as follows:

[0058] Based on the dry basis of the finished product as 200kg:

[0059] 10-30 mesh coal-based granular activated carbon 180kg;

[0060] Ferrous sulfate heptahydrate 9.0kg;

[0061] Titanium tetrachloride 11.0kg.

[0062] Prepare as follows:

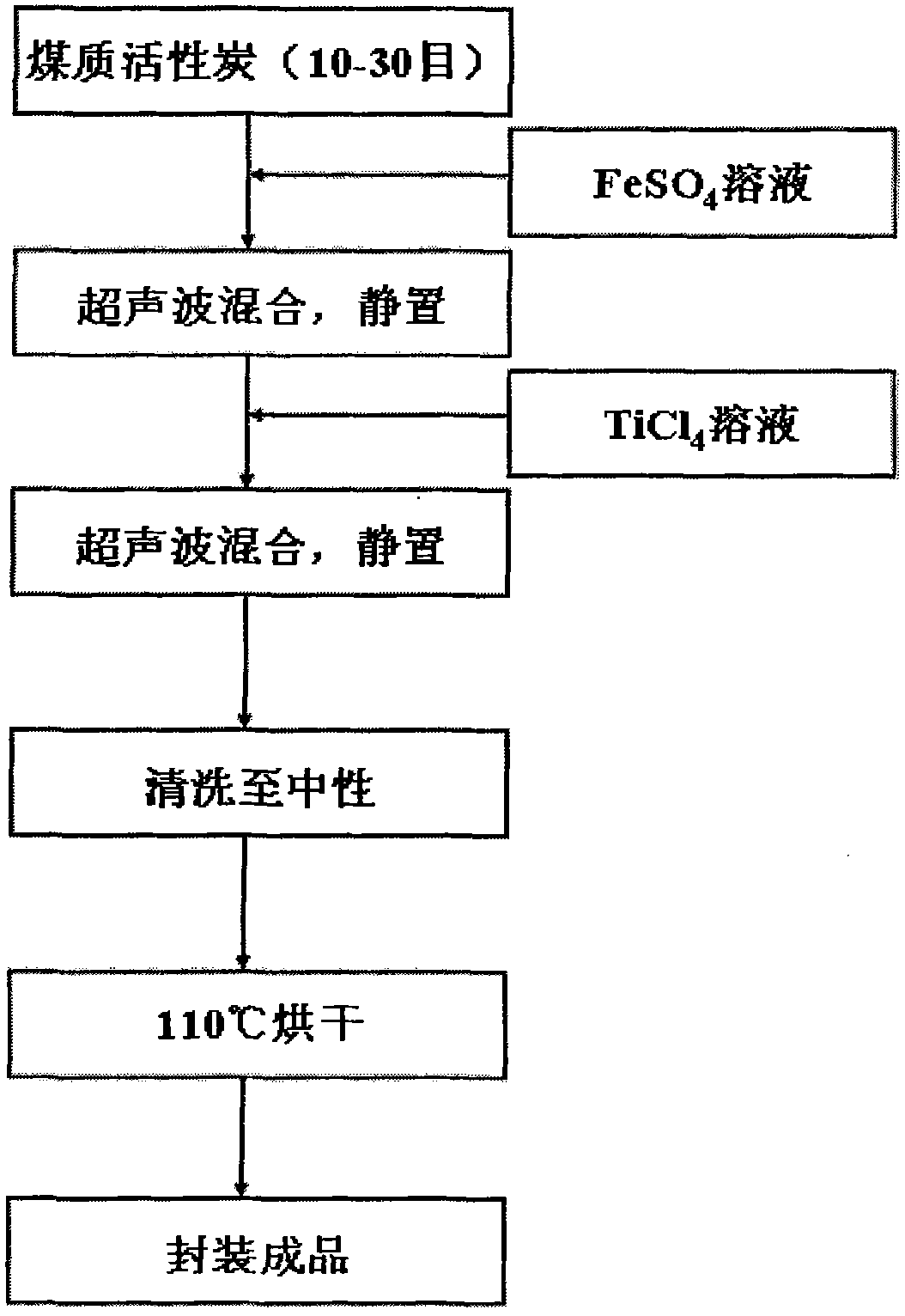

[0063] 1) Prepare FeSO with a certain amount of water according to the formula 4 Solution, immerse 10-30 mesh coal-based granular activated carbon into FeSO 4 In the solution, ultrasonic wave was mixed at 50°C for 30 minutes, left to stand for 24 hours, and the supernatant was poured out to obtain material 1;

[0064] 2) Prepare TiCl with a certain amount of water according to the formula 4 solution, material 1 was immersed in TiCl 4 In the solution, use an ultrasonic wave with a working frequency of 40KHz to mix at 50°C for 30 minutes, let it stand for 24 hours, and pour out the supernatant to obtain material 2;

[0065] 3) ...

Embodiment 2

[0068] According to the preparation method of embodiment 1, present embodiment is wherein another formula, and the component by weight is as follows:

[0069] Based on the dry basis of the finished product as 200kg:

[0070] 10-30 mesh coal-based granular activated carbon 175kg;

[0071] Ferrous sulfate heptahydrate 4.5kg;

[0072] Titanium tetrachloride 21.5kg.

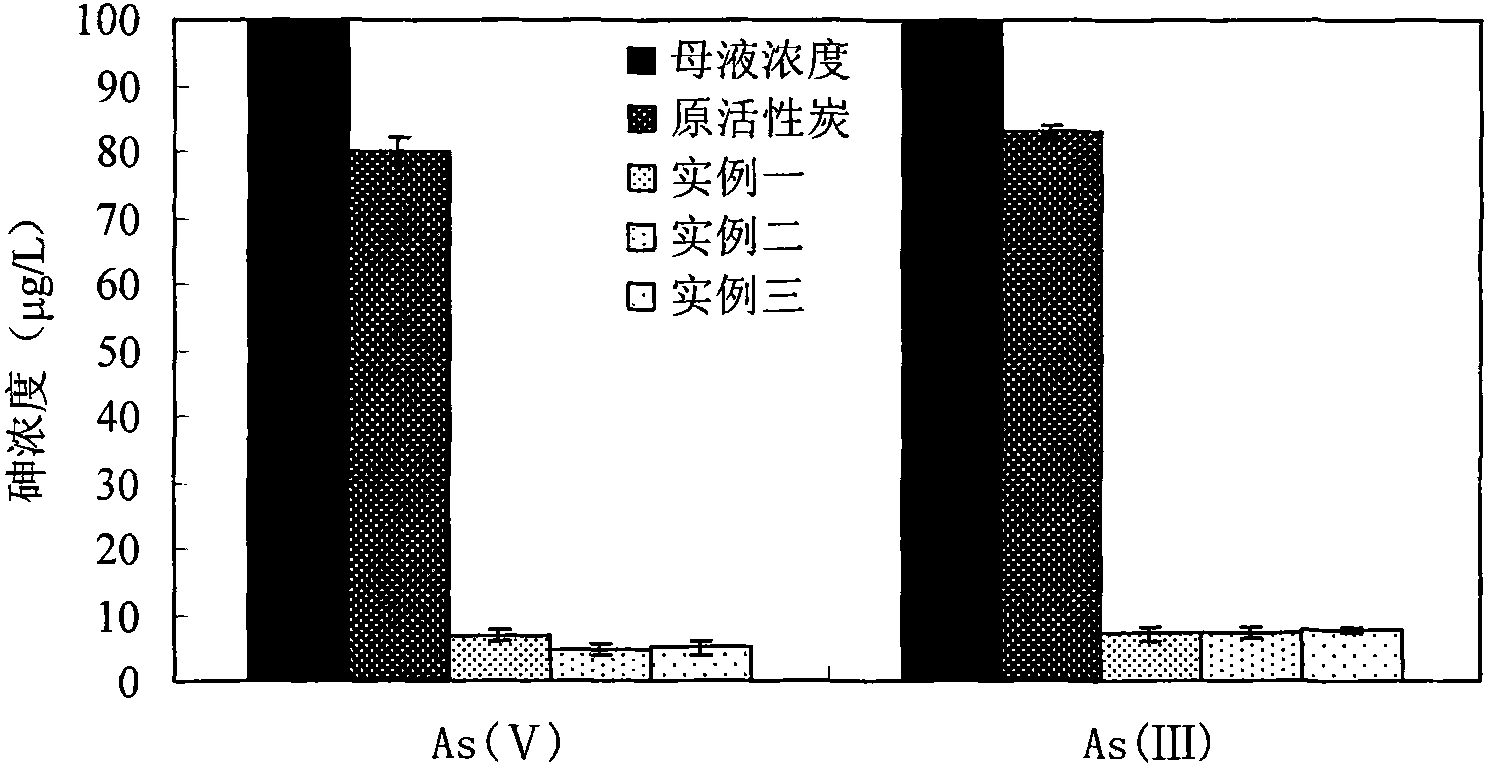

[0073] The adsorption material prepared in this example is used to adsorb As(V) / As(III) simulated arsenic-containing wastewater prepared with 100 μg / L As(V) / As(III) standard stock solution under laboratory conditions, so that The adsorption rate of As(V) increased from 20.12% of the original 10-30 mesh granular coal-based activated carbon to 95.45%, the concentration of As(V) dropped to 4.55 μg / L, and the adsorption rate of As(III) increased from 17.07 % increased to 92.65%, As(III) concentration dropped to 7.35μg / L (see figure 2 ).

Embodiment 3

[0075] According to the preparation method of embodiment 1, present embodiment is wherein another formula, and the component by weight is as follows:

[0076] Based on the dry basis of the finished product as 200kg:

[0077] 10-30 mesh coal-based granular activated carbon 170kg;

[0078] Ferrous sulfate heptahydrate 9.0kg;

[0079] Titanium tetrachloride 21.5kg.

[0080] The adsorption material prepared in this example is used to adsorb As(V) / As(III) simulated arsenic-containing wastewater prepared with 100 μg / L As(V) / As(III) standard stock solution under laboratory conditions, so that Its adsorption rate for As(V) increased from 20.12% of the original 10-30 mesh granular coal-based activated carbon to 95.10%, the concentration of As(V) dropped to 4.90 μg / L, and the adsorption rate for As(III) increased from 17.07 % increased to 92.34%, As(III) concentration dropped to 7.66μg / L (see figure 2 ).

[0081] According to the technical solutions and examples provided by the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption rate | aaaaa | aaaaa |

| Adsorption rate | aaaaa | aaaaa |

| Adsorption rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com