Engine starting control system and method

An engine and engine starting technology, applied in the direction of engine control, engine components, combustion engine, etc., can solve the problems of deteriorating engine, increasing exhaust heat, not having rich condition package, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

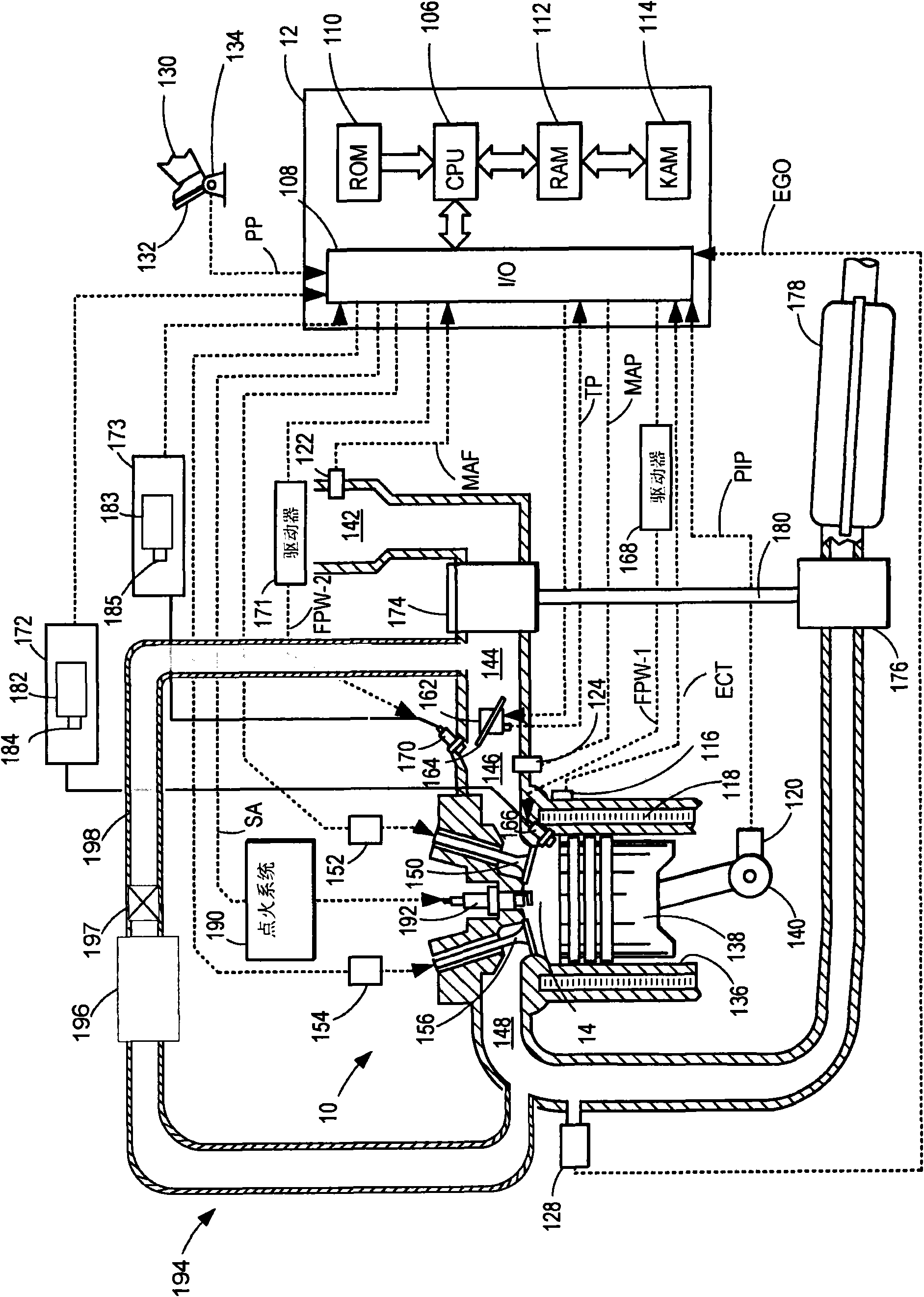

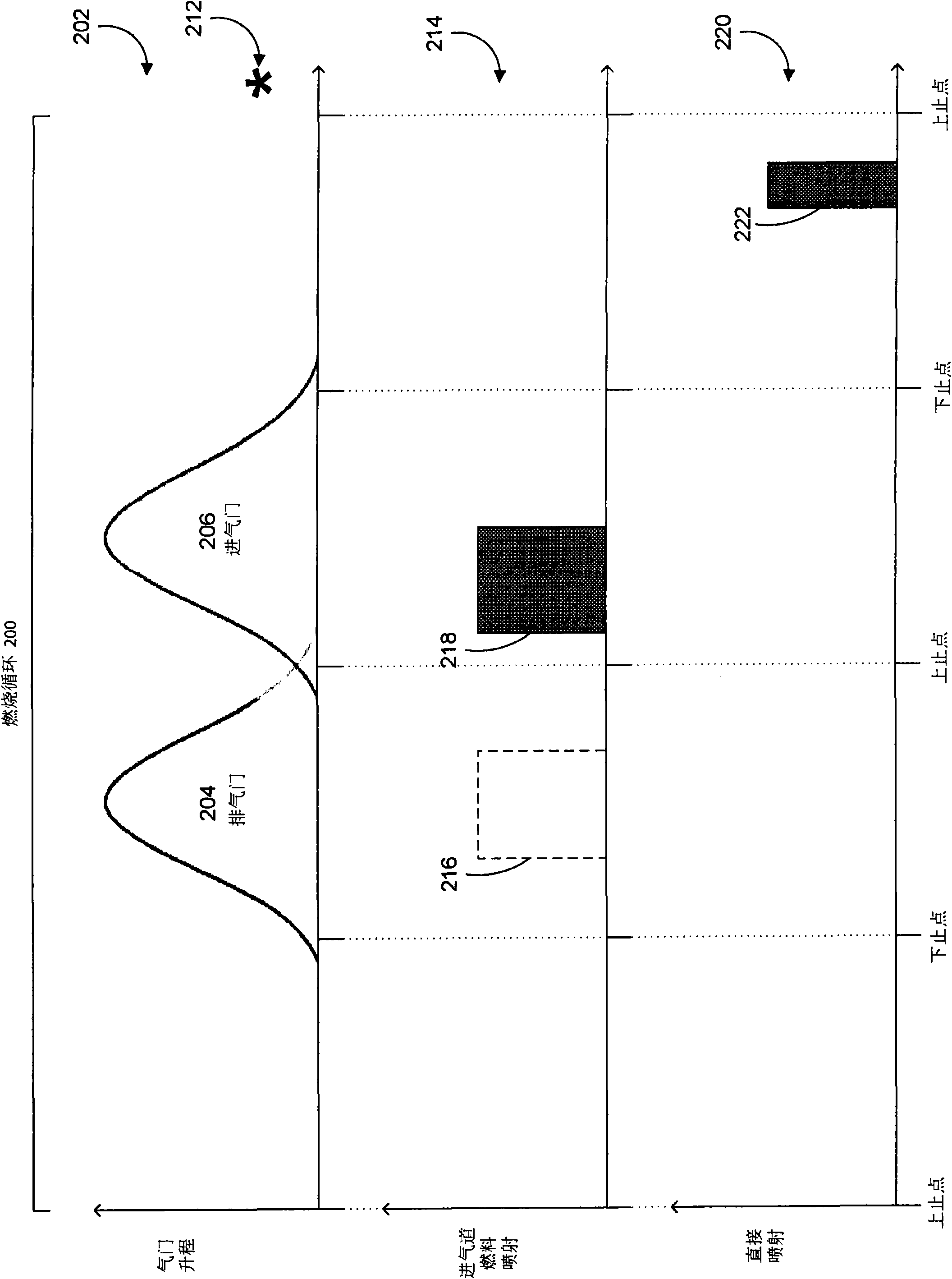

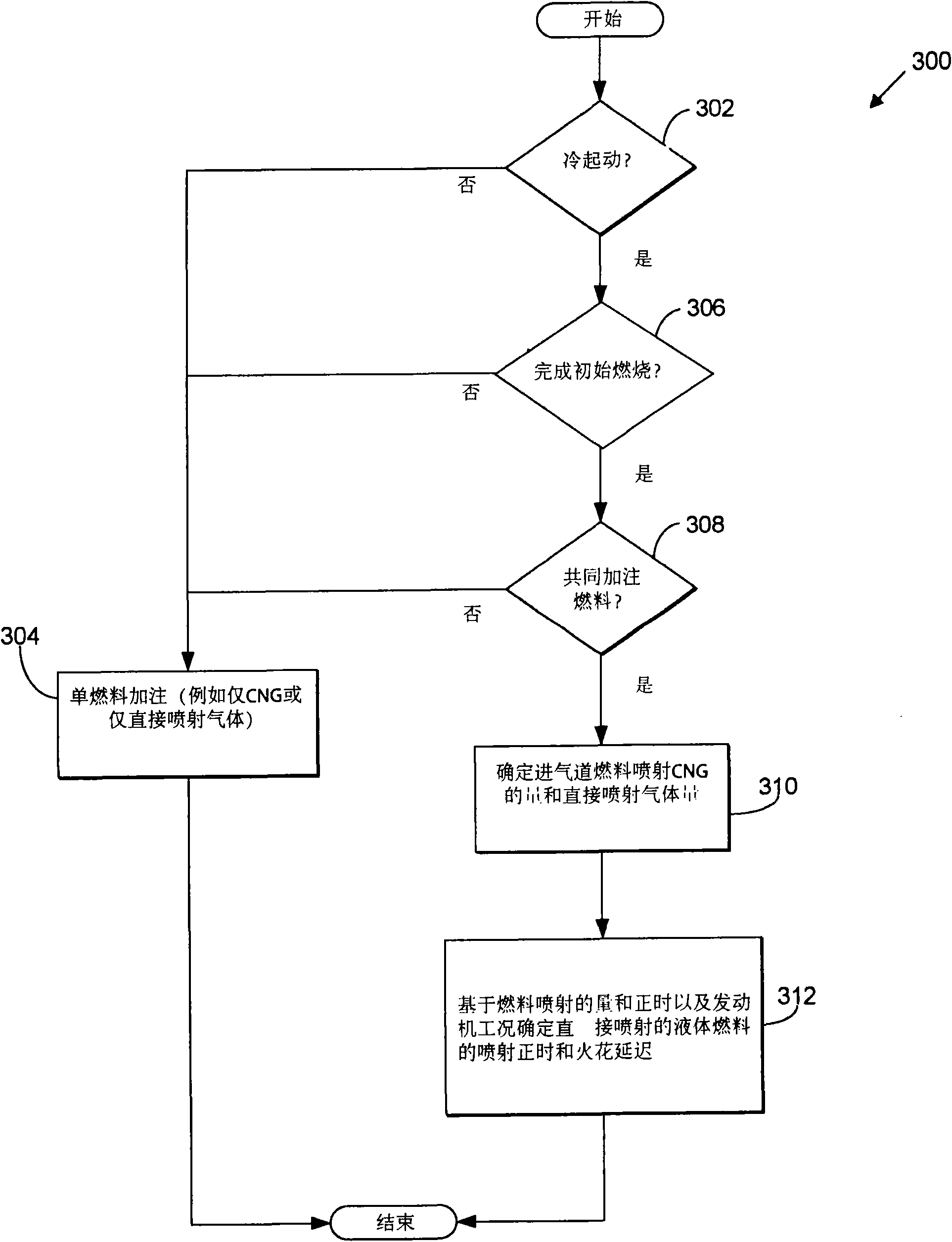

[0012] figure 1 A vehicle engine system is described in which can operate with gaseous fuel and liquid fuel injected separately and / or simultaneously into the combustion chamber. In one example, the gas fuel may include natural gas (CNG), and the liquid fuel may include direct injection (DI) gasoline. Such as figure 2 The example chart illustrates that during engine start, a well-mixed gaseous fuel injection can be used together with a rich cloud of liquid fuel formed near the spark plug to enable increased spark timing retardation. image 3 An example method for controlling fuel injection and other operating parameters of an engine is described, in which the amount and timing of liquid and / or gas fuel injection are adjusted in coordination with each other to achieve reliable combustion during engine start, and reduce engine emissions and faster catalysts Ignite. Alternatively, you can use Figure 4 The coordination of liquid fuel and gaseous fuel injection described in solves...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com