Blackbody radiation boiler and manufacturing method thereof

A technology of black body radiation and manufacturing method, applied in steam generation method, fluid heater, steam generation and other directions, can solve the problems of insufficient utilization of thermal energy, large overall structure of the boiler, and increased operating cost, and achieves simple structure, High operating efficiency and improved environmental protection function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

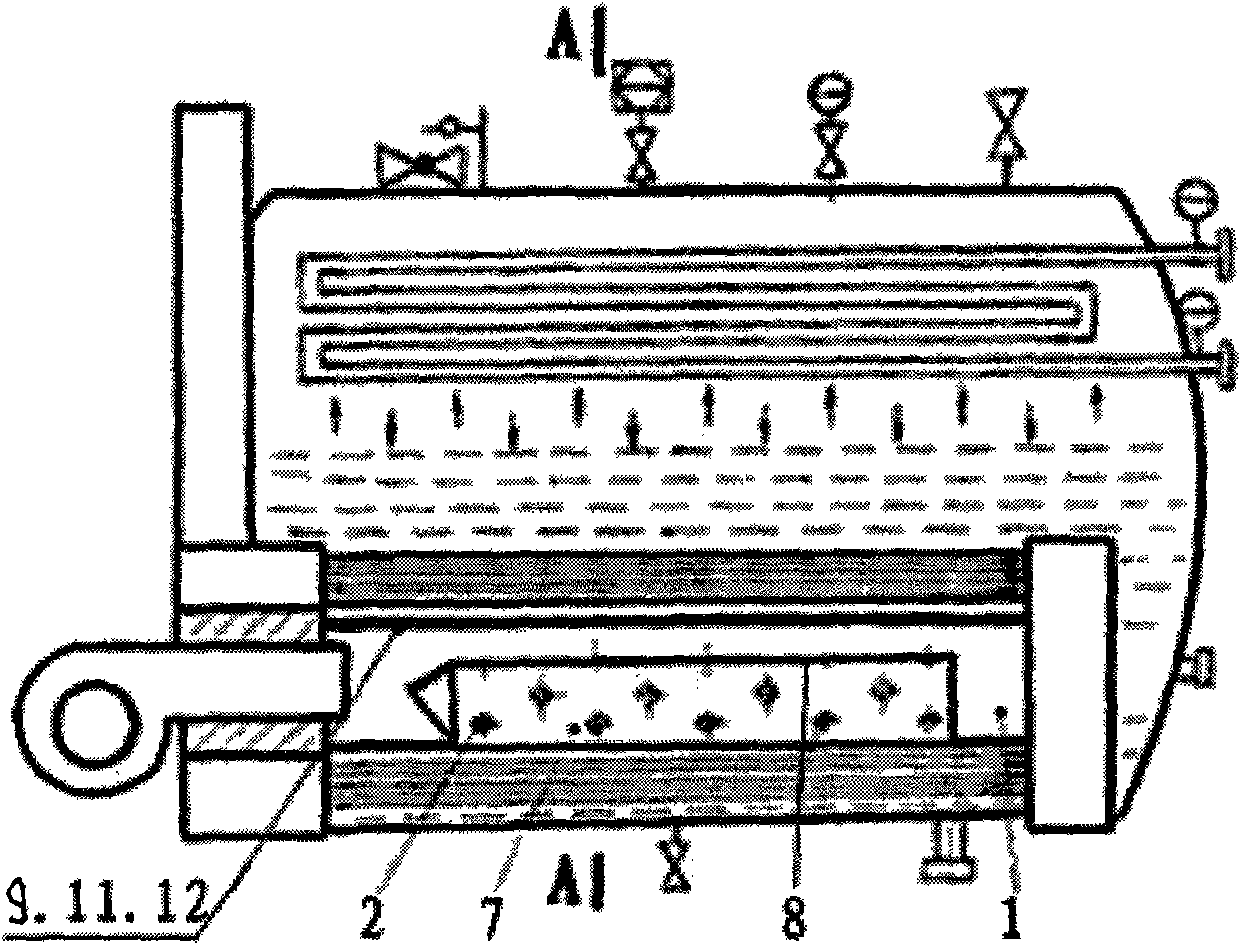

[0031] Embodiment 1: black body radiation fire tube boiler and its manufacturing method

[0032] Such as figure 1 , 2 , 3, the blackbody radiation fire tube boiler of the present invention includes a furnace 1, and 20 blackbody elements 2 are arranged in the furnace 1.

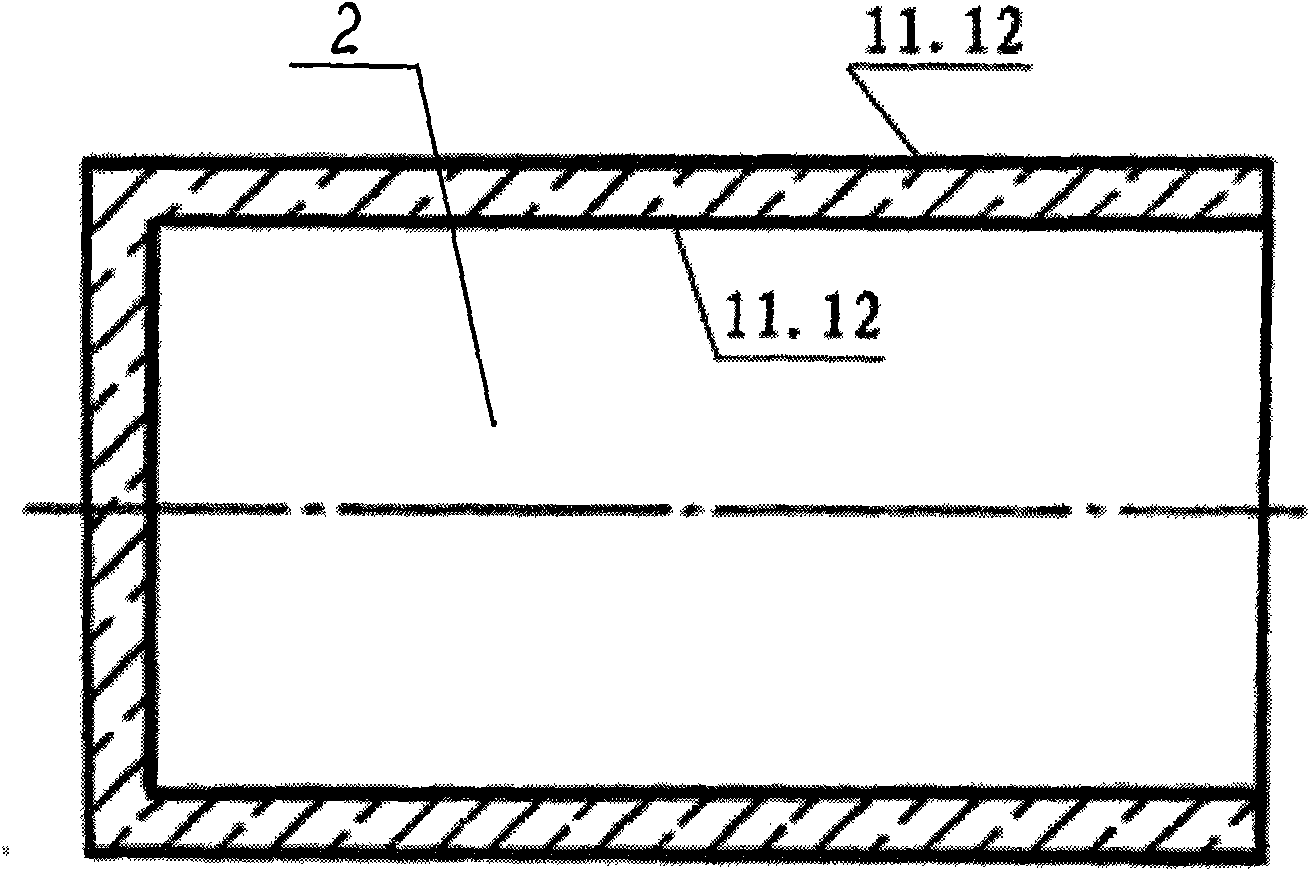

[0033] The inner and outer surfaces of the above-mentioned blackbody element 2 are compounded with a strengthened treatment layer 11 and an infrared coating 12 .

[0034] The center-to-center distance between the above-mentioned adjacent blackbody elements 2 is 200mm, so as to meet the requirement of furnace temperature uniformity.

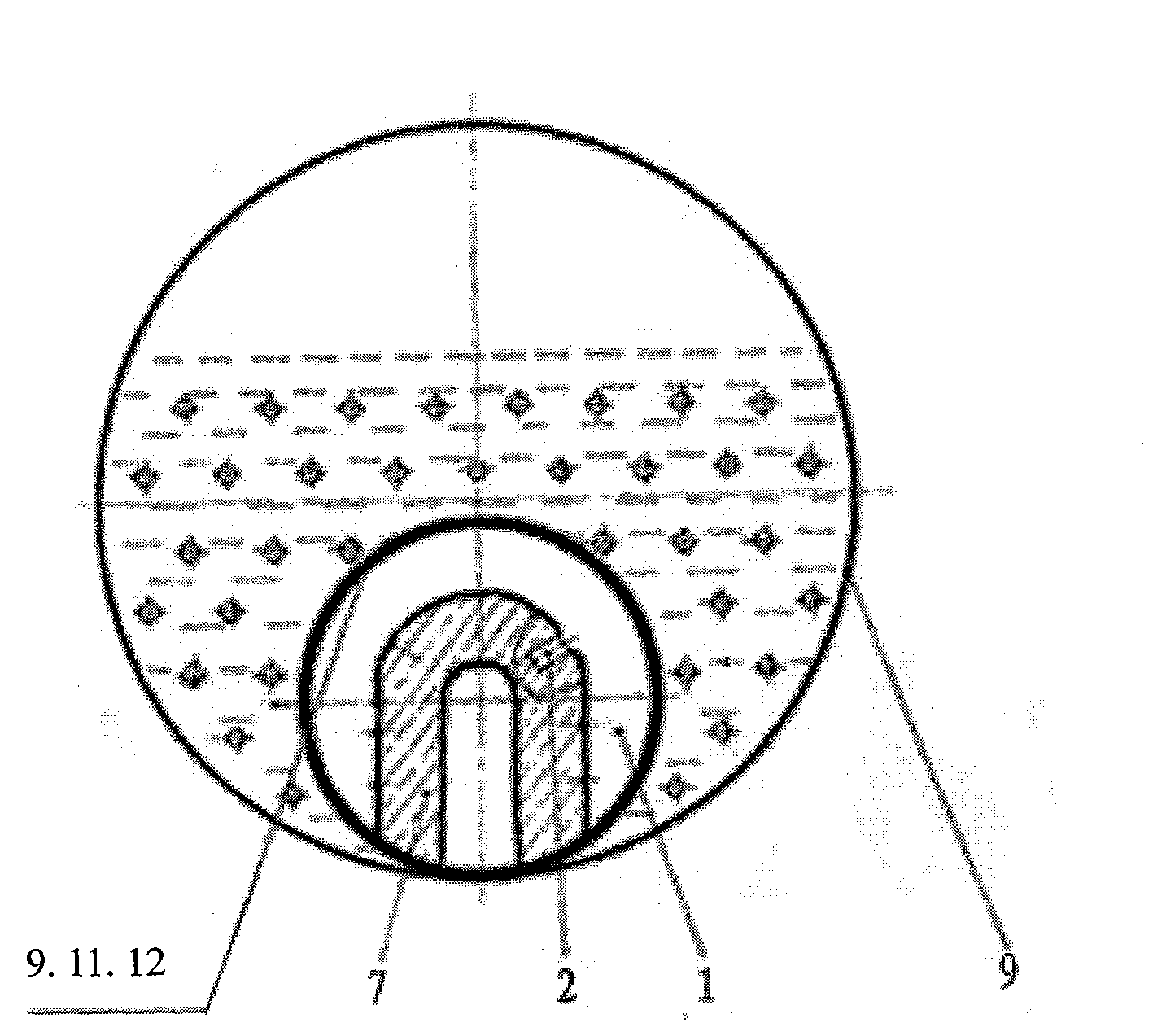

[0035] The shape of the above-mentioned black body element 2 is a cylindrical shape with an open end.

[0036] The above-mentioned furnace 1 has a blackbody element carrier 7 supported in the furnace 1 , and the blackbody element 2 is mounted on the blackbody element carrier 7 .

[0037] The working surface 8 of the above-mentioned blackbody element carrier 7 faces the heating...

Embodiment 2

[0049] Embodiment 2: Black body radiation chain row boiler and its manufacturing method

[0050] Such as figure 1 , 4 As shown, the blackbody radiant boiler of the present invention has 50 blackbody elements 2 in the furnace, the shape of the blackbody elements 2 is a hollow cone shape, the center distance between the blackbody elements 2 is 100 mm, and the blackbody elements 2 are fixed on the furnace 1 On the front and rear arches 4 and 5 of the furnace wall 3, the blackbody element 2 is fixed by heat-resistant screws and sintered together with the front and rear arches 4 and 5. Except for the manufacture and installation of the blackbody element 2, the rest are the same as in Example 1 . The black body element 2 is installed on the front and rear arches 4 and 5 of the chain row boiler. The installation position of the black body element 2 on the front arch 4 makes the heat rays emitted by the black body element 2 just hit the ignition position of the coal, so that the fir...

Embodiment 3

[0051] Embodiment 3: blackbody radiant fluidized bed boiler and its manufacturing method

[0052] Such as figure 1 , 5 As shown, the blackbody radiant boiler of the present invention has 100 blackbody elements 2 in the furnace 1, the shape of the blackbody elements 2 is a combined shape of a cylinder and a cavity cone, and the center distance between the blackbody elements 2 is 280 mm. Except for installing the blackbody element 2, the others are the same as in Embodiment 1. The black body element 2 is installed on the furnace wall 3 of the furnace 1 in the dilute-phase zone of the fluidized bed boiler to increase the temperature of the furnace 1 and improve the pulverized coal combustion condition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com