High-precision capacitance-type displacement sensor for direct non-contact detection of mirror surface high-low difference

A technology of displacement sensor and height difference, which is applied in the direction of instruments, measuring devices, and electric devices, etc., can solve the problems of limited detection batches, limited use occasions, and impact on measurement accuracy, and achieve compact structure, high detection accuracy of height difference, and high-quality workmanship. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

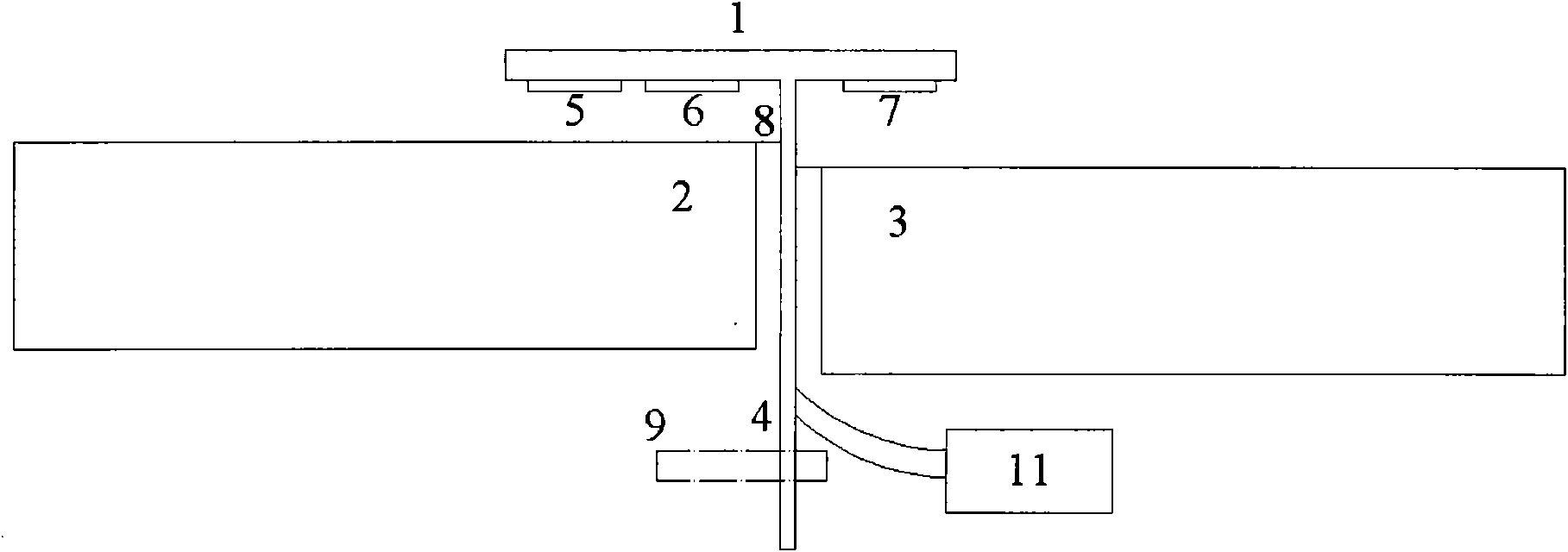

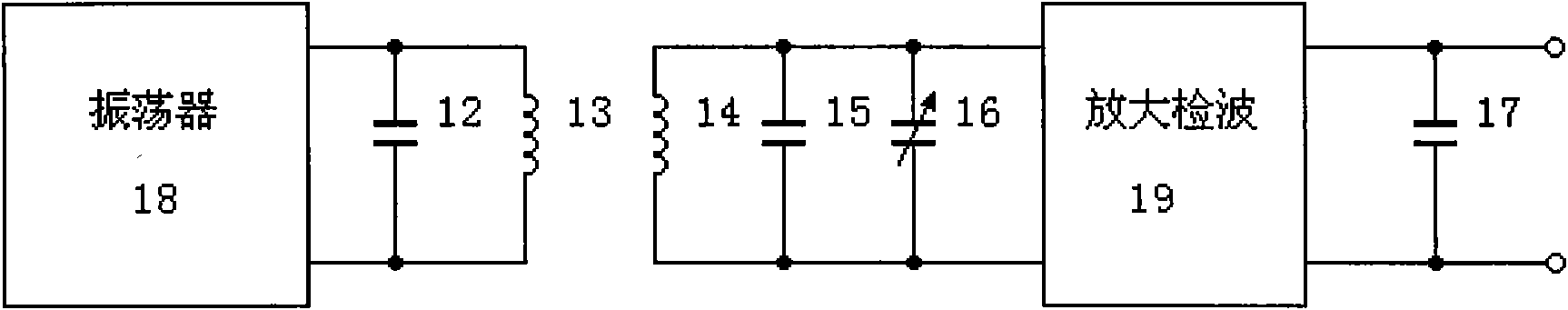

[0032] Example 1, reference figure 1 : On the reference plate 1 above the two mirrors 2, 3 in the figure, two capacitive sensor positive plates 5, 6 and one capacitive sensor positive plate 7 are respectively arranged (here for the symmetrical type, there are two, respectively, 7 and 10), along the straight line, to eliminate the tilt error of the reference base, and the negative plate of the capacitive sensor uses the mirror metal reflective film or the metal mirror itself. The reference base of the capacitive sensor is connected to the truss 9 of the mirror support system through The method of pre-calibration is used to determine the system error of the sensor, which mainly comes from the area of the capacitor plate and the capacitor spacing, etc., and adjust the approximate verticality of the capacitor reference base 1 and the truss connection mechanism 4 before installation (the sensor plate and the mirror are roughly parallel , The error is small) and through the connect...

Embodiment 2

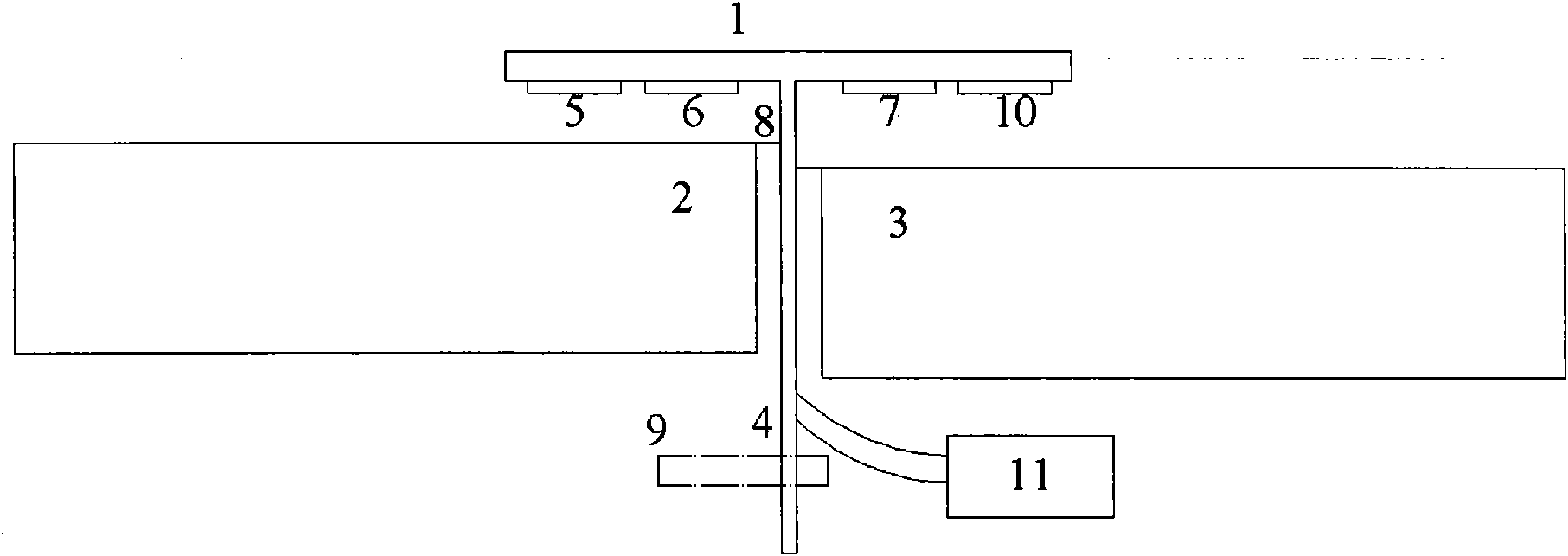

[0033] Example 2, reference figure 2 : It is basically the same as the first embodiment, but there are two capacitive sensor positive plates arranged on the reference plate 1 above the two mirrors 2, 3, which are 7 and 10 respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com