Deformed secondary mirror based on piezoelectric driver

A piezoelectric driver and driver technology, applied in the direction of instruments, optical components, optics, etc., to achieve the effect of compact structure, low heat generation, and small total mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

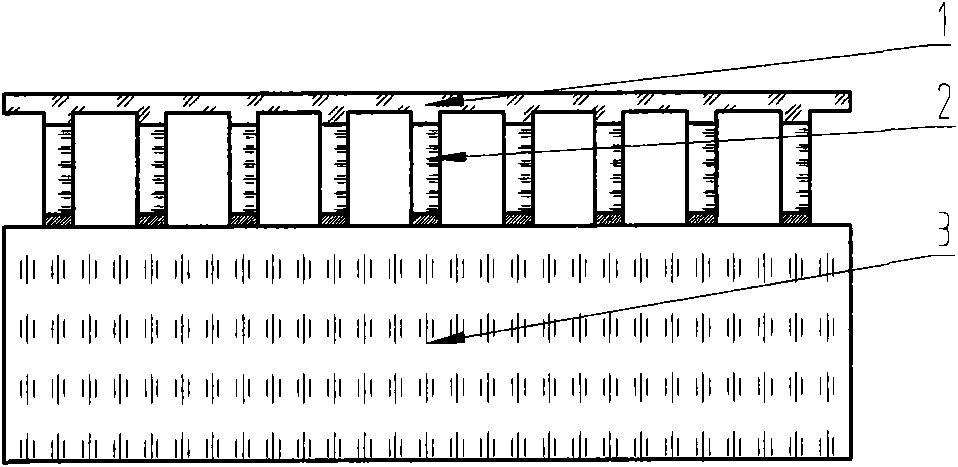

[0018] Such as figure 2. As shown, the mirror 1, the piezoelectric driver 2 and the rigid base 3 of the present invention are bonded to form a piezoelectric deformable secondary mirror supported by the rigid base 3, the piezoelectric driver 2 as the driving mechanism, and the mirror 1 as the reflecting surface.

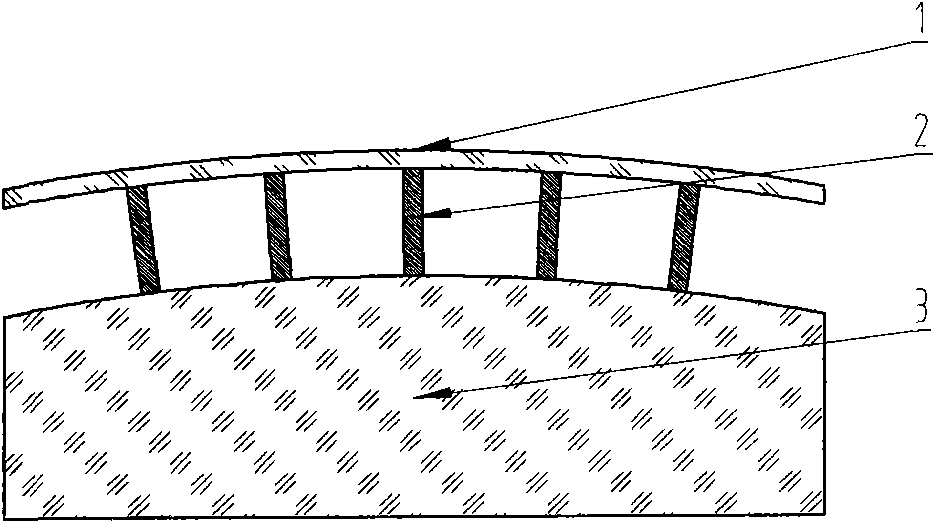

[0019] Such as image 3. As shown, the mirror surface 1 is a spherical shell structure, and its upper surface is an aspherical surface. The distance from the joint surface to the mirror surface reduces the local deformation residual caused by the bonding process. The mirror surface 1 material can be selected according to actual requirements such as glass, beryllium, silicon, aluminum, etc., which can be used as reflector materials.

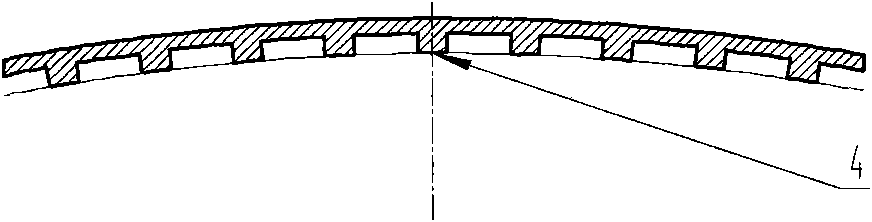

[0020] Such as Figure 4 As shown, the driver 2 is a laminated piezoelectric driver, and its two ends are bonded with matching joints 5 and 7 respectively, so as to ensure that the driver is in close contact with the lower surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com