Method for directly driving ordering of atoms of magnetic recording medium film by current

A magnetic recording medium and film technology, which is applied in the manufacture of record carriers and other directions, can solve the problems of large heat energy consumption and low effective utilization rate, and achieve the effects of simple preparation, simple structure and improved effective utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

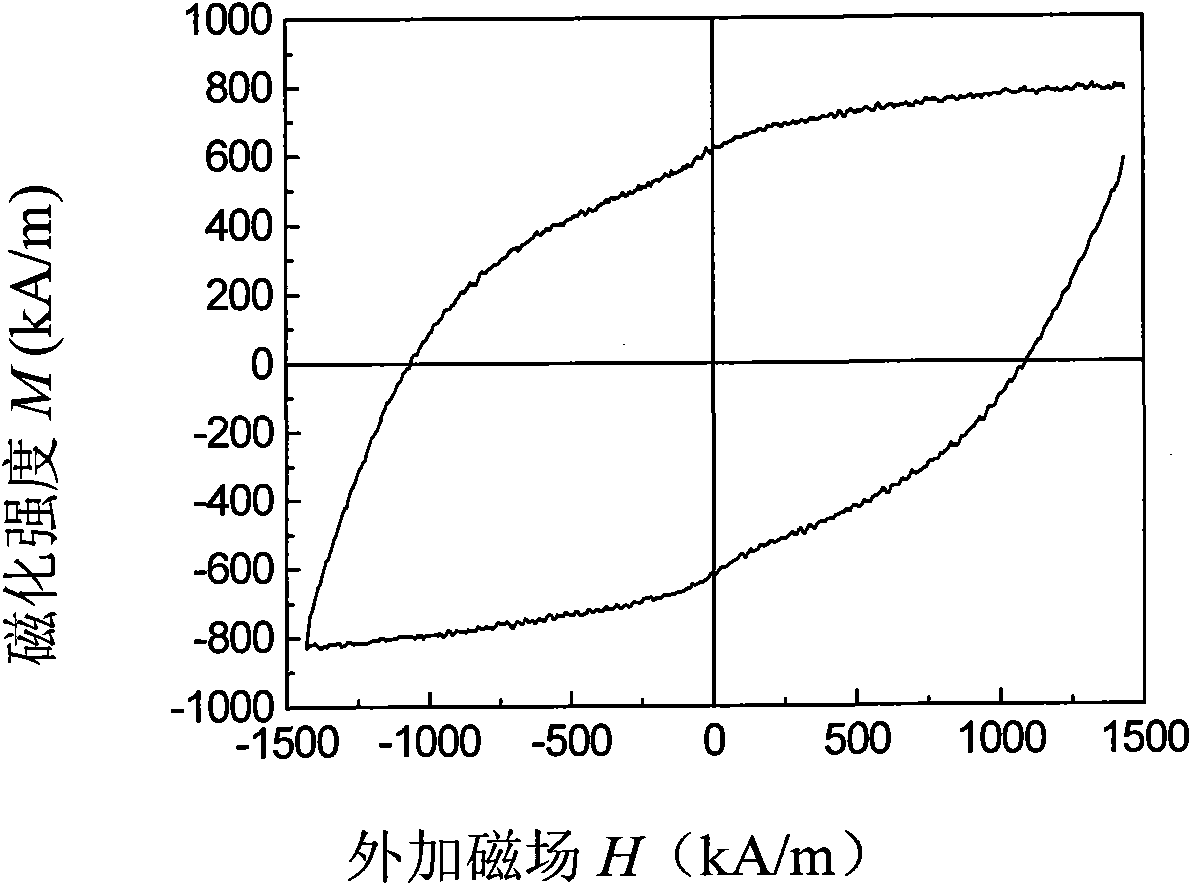

[0015] Embodiment one, figure 1 The representative thin film sample is the implementation case 1 of current-driven atomic order of the present invention, and its preparation process conditions are: the background vacuum degree of the sputtering chamber is 1×10 -5 , Argon (99.99%) pressure is 0.4Pa during sputtering; substrate temperature is 20°C. After the deposition is completed, the film is lowered to room temperature, and Cu electrodes are drawn from both ends of the film and connected to a constant current source. Put the sample into the vacuum furnace and wait until the vacuum degree in the furnace is 2×10 -5 At Pa, a current (provided by a constant current source) was passed through both ends of the film, the magnitude of the current was 300mA, and the duration of the current was 5 seconds.

[0016] figure 2 The representative thin film sample is the comparative case 1 of traditional vacuum annealing, and its preparation process conditions are: the background vacuum ...

Embodiment 2

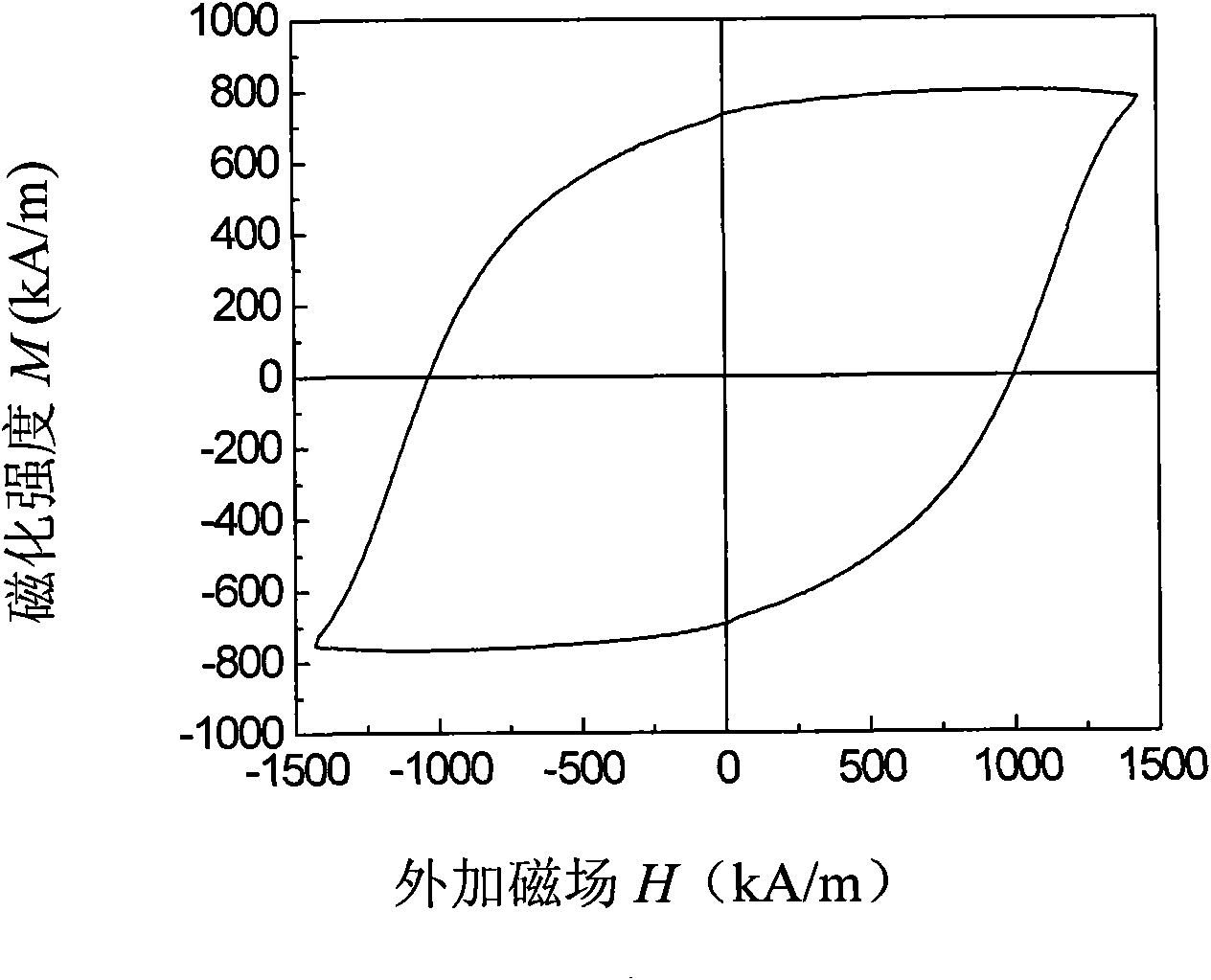

[0017] Embodiment two, image 3 The representative thin film sample is the implementation case 2 of current-driven atomic order of the present invention, and its preparation process conditions are: the background vacuum degree of the sputtering chamber is 4×10 -5 , Argon (99.99%) pressure is 0.7Pa during sputtering; substrate temperature is 400°C. After the deposition is completed, the film is lowered to room temperature, and Cu electrodes are drawn from both ends of the film and connected to a constant current source. Put the sample into the vacuum furnace and wait until the vacuum degree in the furnace is 2×10 -5At Pa, an electric current (provided by a constant current source) is applied to both ends of the film, the magnitude of the electric current is 100 mA, and the electrification time is 15 seconds.

[0018] Figure 4 The representative film sample is the comparative case 2 of traditional vacuum annealing, and its preparation process conditions are: the background v...

Embodiment 3

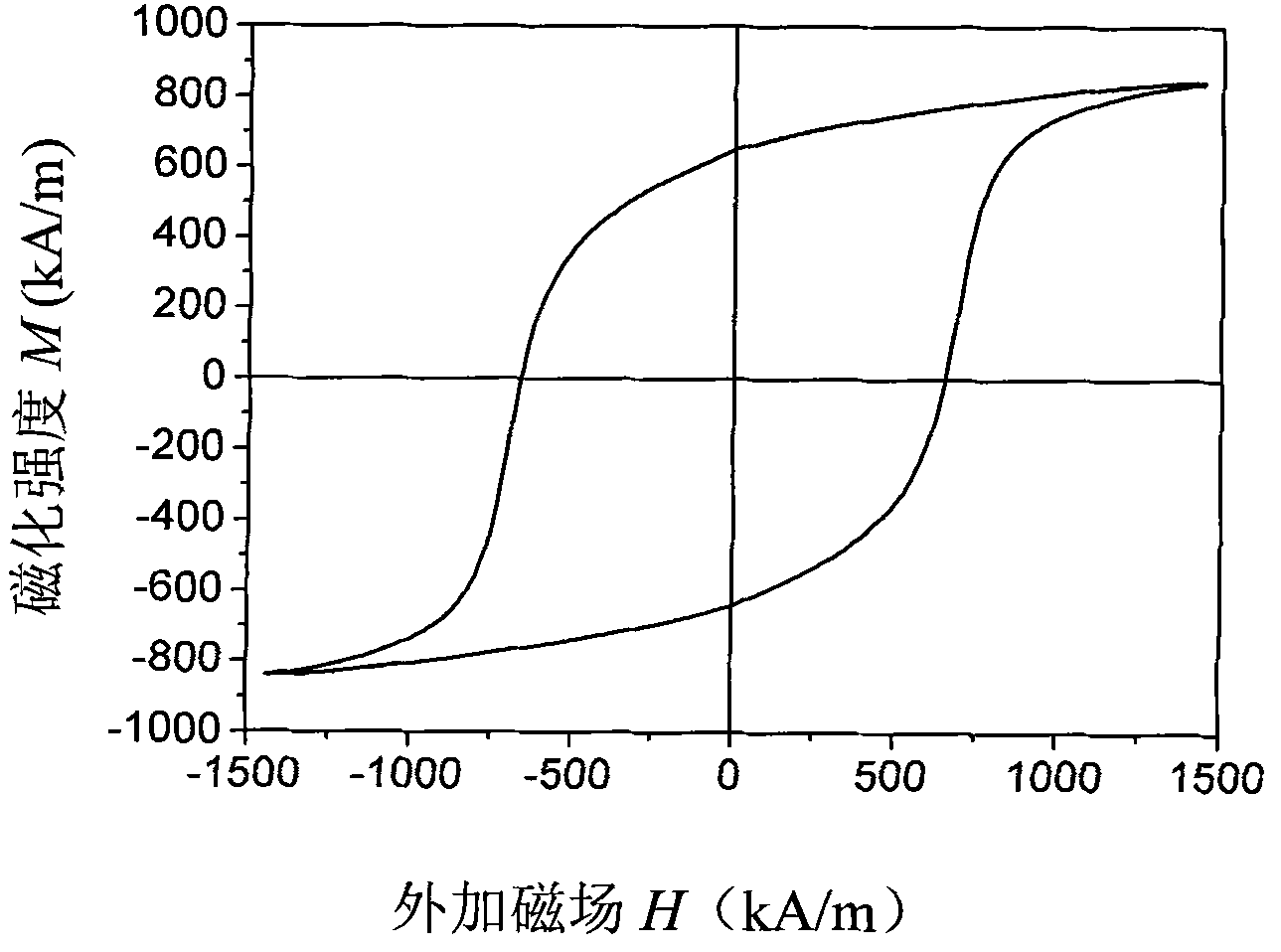

[0019] Embodiment three, Figure 5 The representative thin film sample is the implementation case 3 of current-driven atomic order of the present invention, and its preparation process conditions are: the background vacuum degree of the sputtering chamber is 7×10 -5 , Argon (99.99%) pressure is 1.2Pa during sputtering; substrate temperature is 800°C. After the deposition is completed, the film is lowered to room temperature, and Cu electrodes are drawn from both ends of the film and connected to a constant current source. Put the sample into the vacuum furnace and wait until the vacuum degree in the furnace is 2×10 -5 At the time of Pa, a current (provided by a constant current source) was passed through both ends of the film, the magnitude of the current was 50 mA, and the duration of the current was 300 seconds.

[0020] Figure 6 The representative thin film sample is the comparative case 3 of traditional vacuum annealing, and its preparation process conditions are: the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com