Cyclone separator of sand blasting machine

A technology of cyclone separator and sandblasting machine, which is applied in the direction of solid separation, separation of solid from solid by air flow, chemical instruments and methods, etc., can solve the problem of not being able to know the location of the abrasive material in the cyclone separator, and achieve reduction The probability of equipment abnormality and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings.

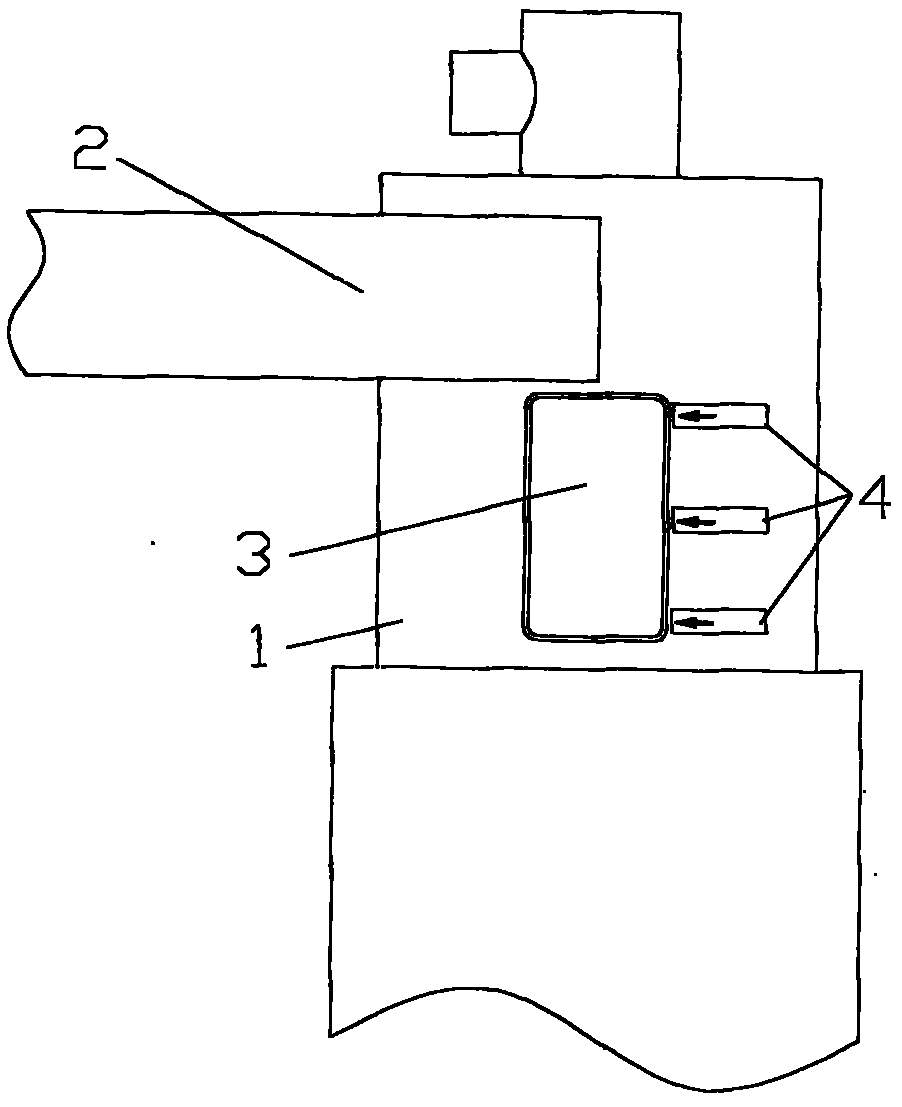

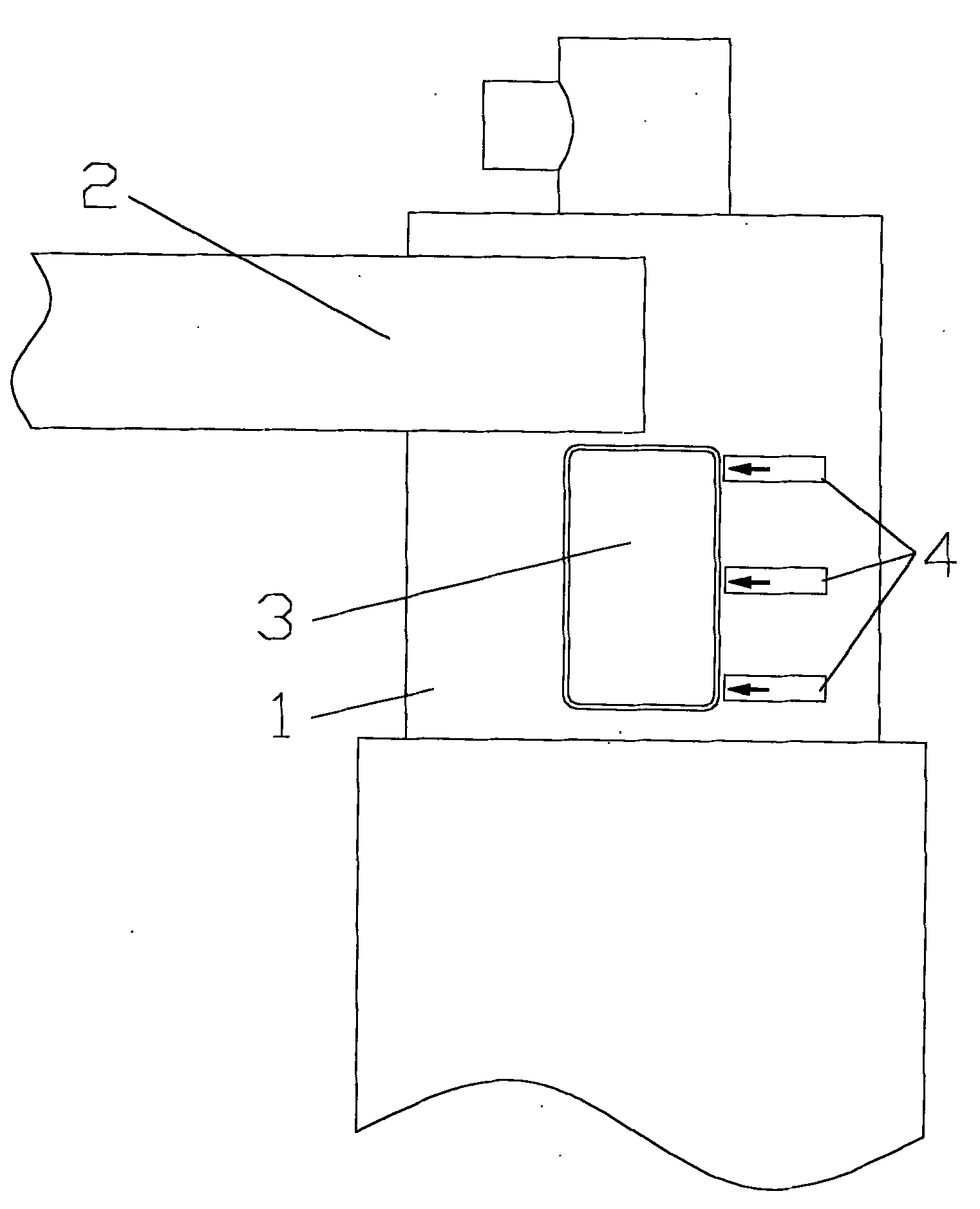

[0011] Such as figure 2 As shown, a sandblasting machine cyclone separator, one end of the sandblasting machine cyclone separator 1 is connected with a sand suction pipe 2, and the surface of the sandblasting machine cyclone separator 1 is provided with an observation window 3, and the observation window 3 is from Three position indicating nameplates 4 are provided in sequence from top to bottom, and the three position indicating nameplates 4 are respectively marked with three marks of the highest position, the standard position and the lowest position. After the abrasive materials with tiny particles and the dust of the grinded materials enter the cyclone separation pipe of the cyclone separator 1 of the sandblasting machine, they are strongly rotated by the flow guide effect of the guide blades, and the tiny particles are sucked away by the centrifugal force, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com