A manufacturing method of a composite sensor package carrier board and a lidar sensor

A technology for packaging a carrier board and a manufacturing method, which is applied in the directions of printed circuit manufacturing, instruments, circuit optical components, etc., can solve the problems of inability to carry out complex and precise circuits, high cost, and difficult processing, and achieves improved miniaturization and integration. Good air tightness and reliability, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1, refer to figure 2 ;

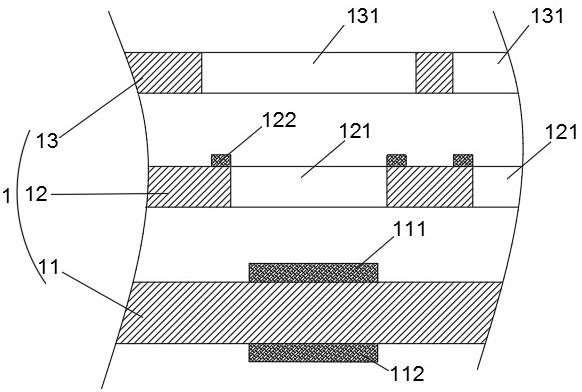

[0035] In the first step, a preset through hole 113 is formed through the PCB circuit substrate 11 by means of mechanical or laser drilling, and then a conductive layer is formed in the through hole 113 by electroplating or filling metal material; Steps such as etching form a functional circuit on the PCB circuit substrate 11, and two sides of the functional circuit are respectively formed with a package pad 1 111 and a package pad 2 112, and a conductive connection is formed through a preset through hole 2 113;

[0036] In the second step, the PCB circuit substrate 11 , the first optical cup board 12 and the second optical cup board 13 are stacked and pressed together to form the package carrier board 1 by vacuum thermocompression bonding with epoxy resin glue. First press the PCB circuit substrate 11 and the first optical cup board 12, and then press the second optical cup board 13 on the first optical cup board 12, or the PCB cir...

Embodiment 2

[0049] Embodiment 2, refer to image 3 ;

[0050] The traditional sensor bonding method requires at least two bonding pads on the package carrier 1, one for die bonding (fixed chip) and the other for bonding bonding wires; The requirements for precision, sensitivity and function of components are getting higher and higher, and the packaging chip circuits used are more complex, which means that more and denser bonding pads are required for connecting bonding wires, which limits the packaging carrier board 1 further miniaturization.

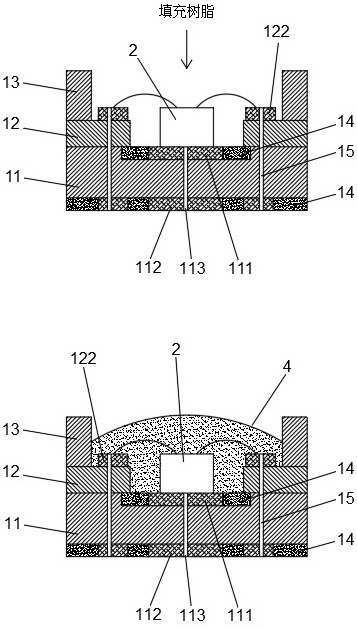

[0051] In view of the above-mentioned problems, the following processing steps are added before and after the second step in the first embodiment:

[0052] Before the second step, the side of the first optical cup board 12 away from the PCB circuit substrate 11 is covered with copper foil, and the first optical cup board 12 and the PCB circuit substrate 11 are covered with epoxy resin glue, so that the packaging of the PCB circuit substrate 11 is...

Embodiment approach

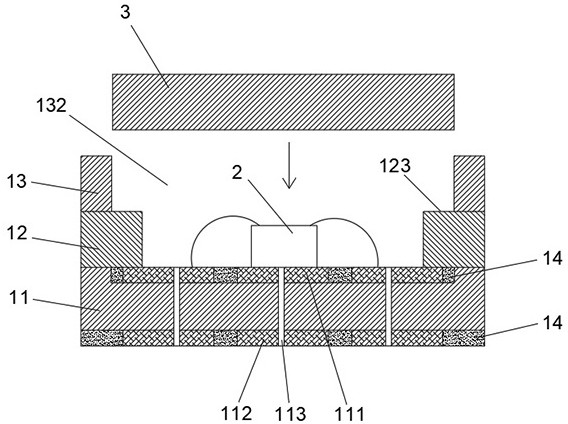

[0055] The present invention also provides a lidar sensor, comprising the above-mentioned package carrier board 1 , a package pad 1 111 in the package carrier board 1 is bonded with a functional chip 2 , and a mounting position 132 located above the functional chip 2 is fixed with a Optical unit, according to the above two embodiments, the lidar sensor also has various implementations, as follows:

[0056] In the first embodiment, the functional chip 2 and the bonding wire are both bonded to the package pad 1 111 located in the first optical cup hole 121, and the optical unit is the optical filter 3, which is installed in the installation position 132. The solution is: It is formed on the basis of the first embodiment, and the technical effect brought by it is the same, and the specific content can refer to the description in the first embodiment;

[0057] In the second embodiment, the functional chip 2 and the bonding wire are both bonded to the package pad one 111 located in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com