Method for removing impurities from coal tar heavy oil

A technology for coal tar and heavy oil, which is applied in the direction of only multi-stage serial refining process, etc., can solve the problems of large equipment size, non-continuous operation, long cycle, etc., save the equipment area and equipment investment, and achieve good separation effect , the effect of reducing the loss of effective components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

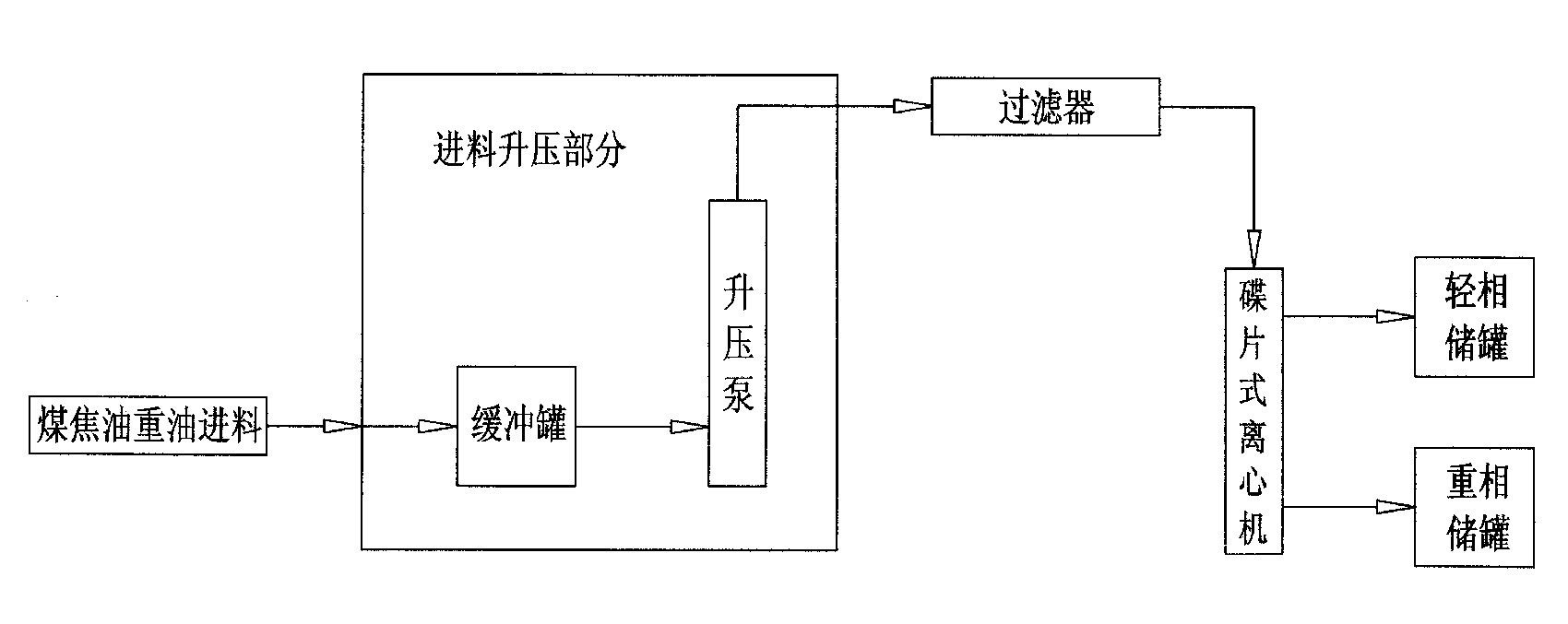

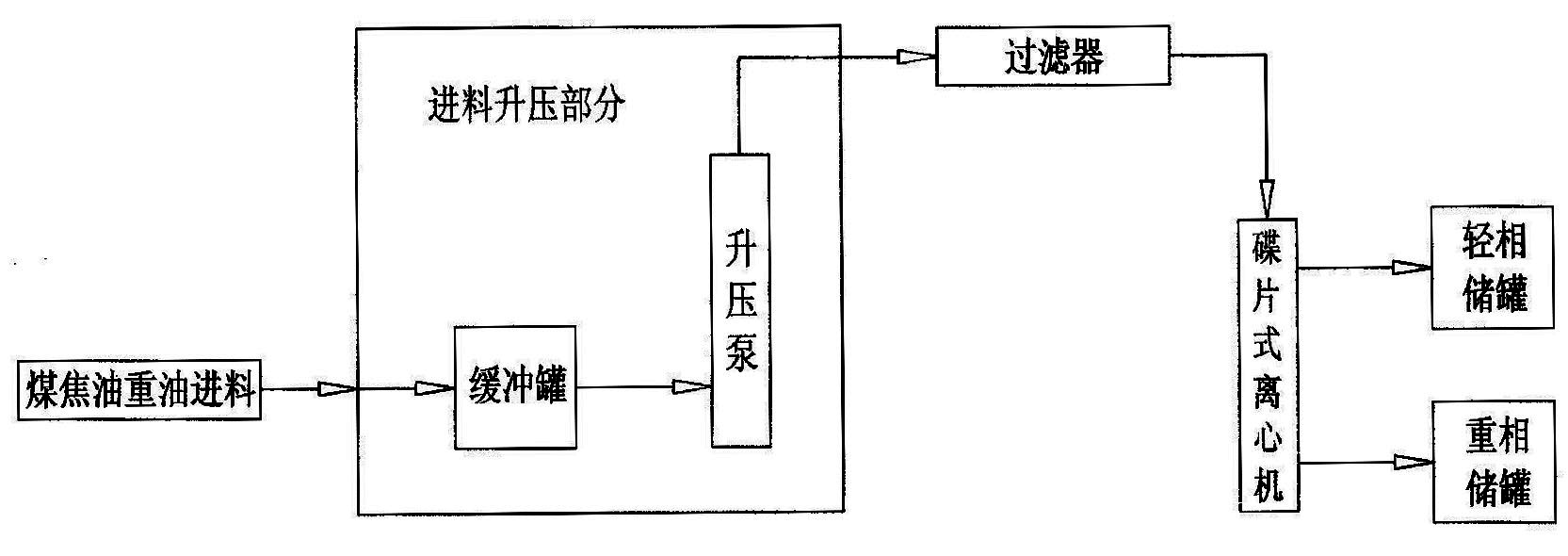

[0022] The feed is coal tar heavy oil with extraction agent, the flow rate is 20t / hr, the pressure is 0.2MPa(G), and the temperature is 80°C. It is sent to the buffer tank by the system, and the pressure is raised to 0.6MPa(G) by the booster pump. Sent to the filter to remove solid impurities above 500μm and prevent larger mechanical impurities from damaging the disc centrifuge; the filtered coal tar heavy oil is sent to the disc centrifuge for separation, the centrifuge speed is 5400rpm, and the light and heavy phases are sent separately Enter the light phase tank and heavy phase tank, of which the light phase is 28t / hr, and the density is 887kg / m 3 , heavy phase 2t / hr, density 986kg / m 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com