Method for separating and purifying hydrogen from water gas by pressure swing adsorption

A pressure swing adsorption method, water gas technology, applied in the separation method, the use of solid contact hydrogen separation, hydrogen separation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Raw gas quality requirements

[0063] components

CO

CH 4

CO 2

O 2

H 2

N 2

Content%

32~40

≤0.2

≤11.0

≤0.4

48~53

≤6.0

[0064] Decarbonization semi-product gas CO 2 ≤0.75%.

[0065] Product CO gas output: 5200Nm 3 / h, temperature: 40°C, pressure: 0.65MPa.

[0066] Product CO purity: CO≥99.0%, CH 4 +H 2 ≤0.2%, CO 2 ≤0.3%, total sulfur ≤0.5ppm, N 2 ≤1.3%, dew point -40℃.

[0067] Product hydrogen output: 9000Nm 3 / h, temperature: 40°C, pressure: 1.3MP.

[0068] Product hydrogen purity: H 2 ≥99.9%, CO≤10ppm, CO 2 ≤10ppm, total sulfur ≤0.5ppm, O 2 ≤20ppm, dew point -40℃.

[0069] The process conditions of each adsorption tower and tank are controlled in the following table:

[0070]

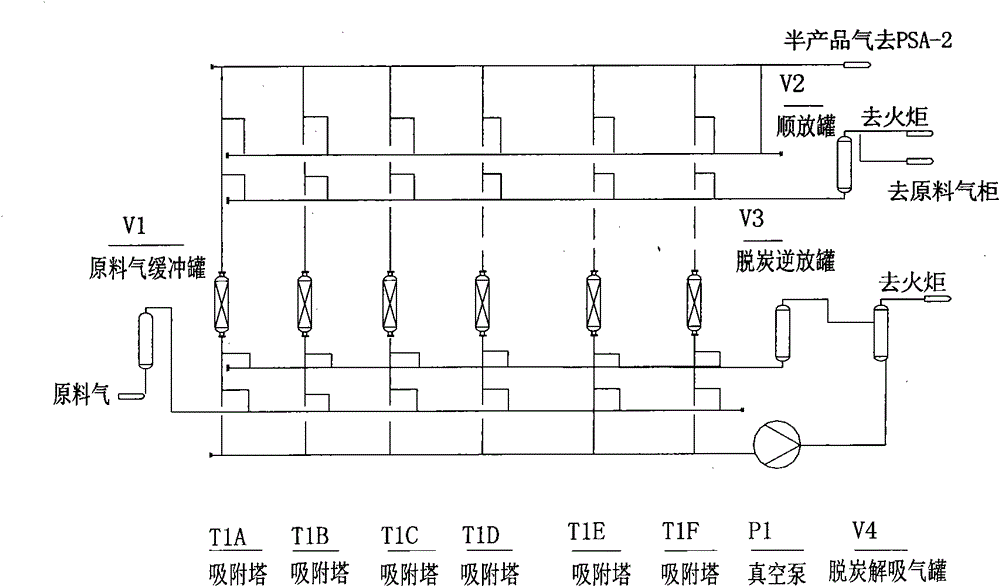

[0071] PSA-1 adsorption regeneration steps and process parameters

[0072]

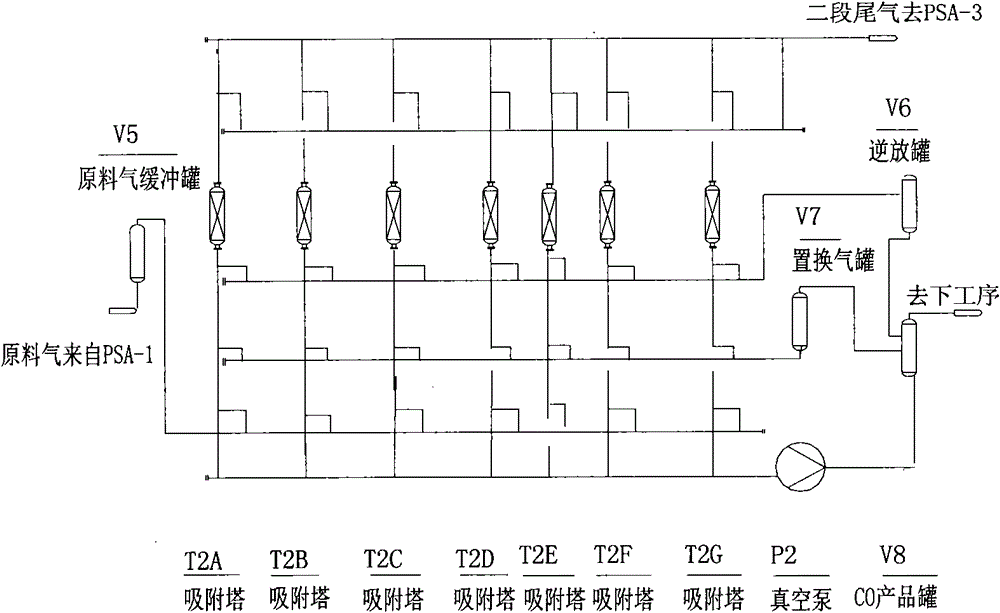

[0073] PSA-2 adsorption regeneration steps and process parameters

[0074]

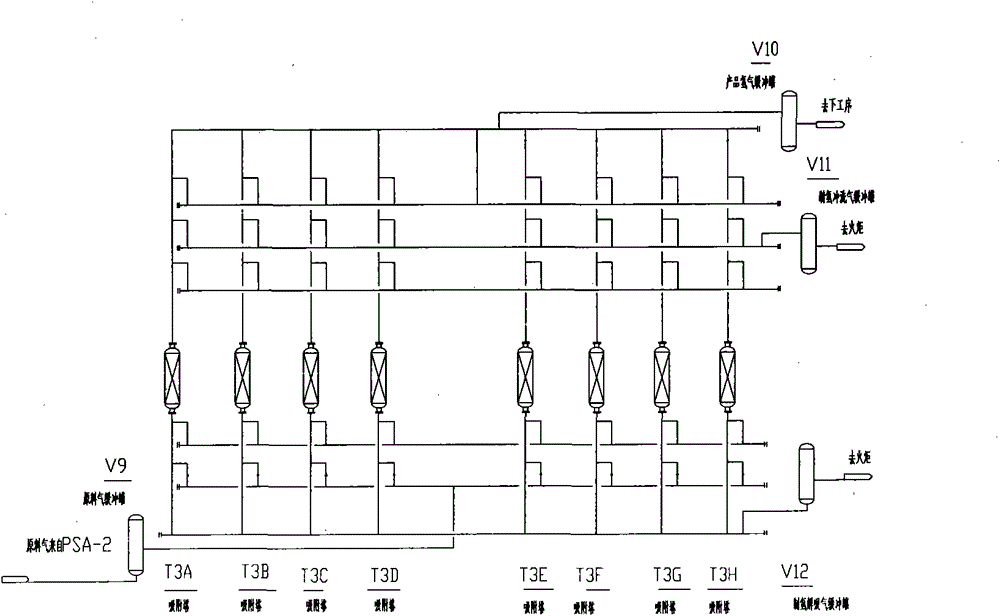

[0075] PSA-3 adsorption ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com