Method for recovering and purifying hydrogen from semi-coke tail gas

A technology of blue carbon tail gas and hydrogen, which is applied in the field of recovering and purifying hydrogen from blue carbon tail gas, can solve the problems of low removal rate of impurity gas, low total hydrogen yield, and organic combination, etc., and achieves remarkable economic benefits and hydrogen recovery. High efficiency and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

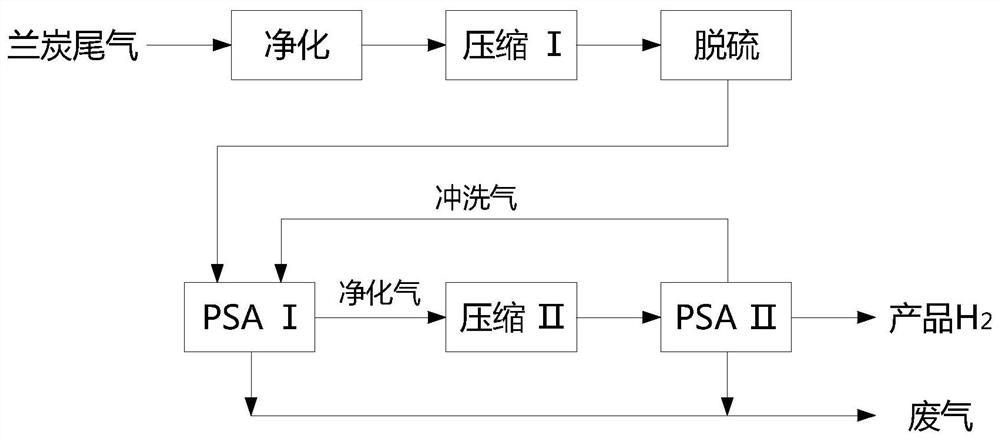

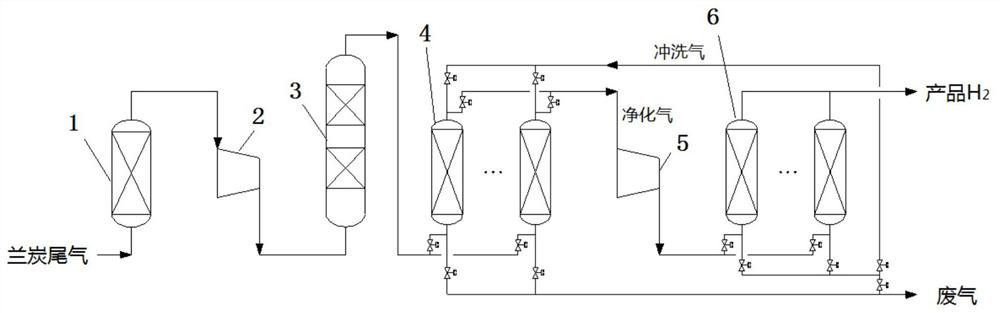

[0066] The method for recovering and purifying hydrogen from semi-coke tail gas in this embodiment, its process flow chart identification figure 1 , the specific method steps are as follows:

[0067] After the semi-coke tail gas is purified, compressed for the first time, desulfurized and other processes, the sulfur content is reduced to 10ppm, and the gas enters the two-stage pressure swing adsorption hydrogen purification device under the pressure of 0.7MPa. The adsorbent loaded in the first stage pressure swing adsorption device (PSA I) is activated carbon, copper-loaded adsorbent and 13X molecular sieve, in terms of volume percentage: the content of activated carbon is 62%, and the content of copper-loaded adsorbent is 18%. The content of 13X molecular sieve is 20%. The first-stage pressure swing adsorption device includes adsorption, three-time pressure equalization, reverse discharge, flushing, three-time pressure equalization, and final filling process steps. The flus...

Embodiment 2

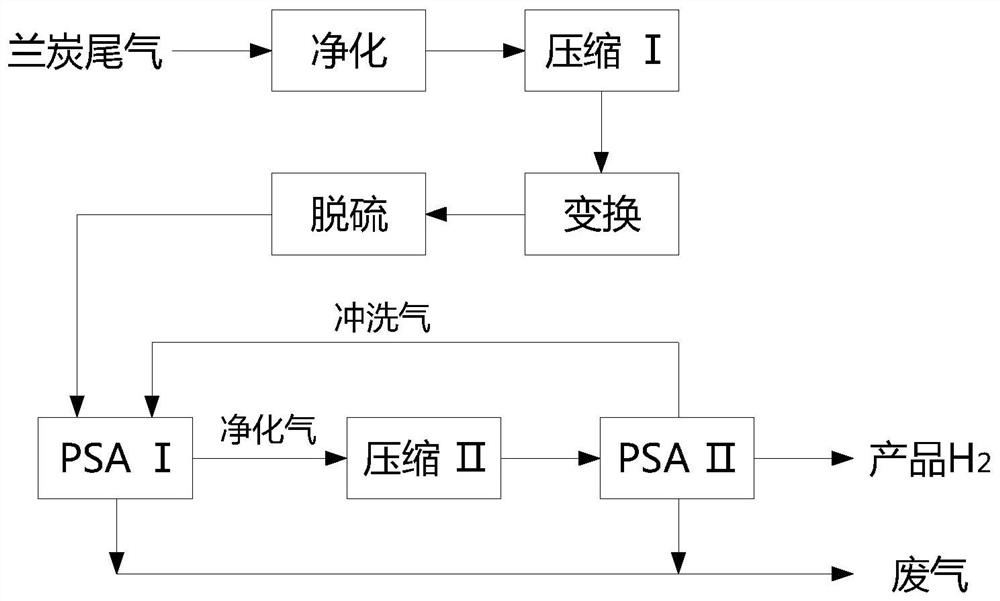

[0073] The method for recovering and purifying hydrogen from blue carbon tail gas in this embodiment is as follows:

[0074] After the semi-coke tail gas undergoes purification, first compression, conversion, desulfurization and other processes, the sulfur content is reduced to 10ppm, and enters the two-stage pressure swing adsorption hydrogen purification device under the pressure of 0.7MPa. The adsorbent loaded in the first pressure swing adsorption device (PSAⅠ) is activated alumina, activated carbon and 13X molecular sieve, in terms of volume percentage: the content of activated alumina is 3%, the content of activated carbon is 82%, 13X molecular sieve The content is 15%. The first-stage pressure swing adsorption device includes adsorption, three-time pressure equalization, reverse discharge, flushing, three-time pressure equalization, and final filling process steps. The flushing gas is the partial desorption gas of the second-stage pressure swing adsorption device, and t...

Embodiment 3

[0080] The method for recovering and purifying hydrogen from blue carbon tail gas in this embodiment is as follows:

[0081] After the semi-coke tail gas undergoes purification, first compression, transformation, desulfurization and other processes, the sulfur content is reduced to 120ppm, and enters the two-stage pressure swing adsorption hydrogen purification device under the pressure of 0.7MPa. The adsorbent loaded in the first stage pressure swing adsorption device (PSA I) is activated alumina, silica gel, activated carbon and 13X molecular sieve, in terms of volume percentage: the content of activated alumina is 5%, the content of silica gel is 10%, The content of activated carbon is 65%, and the content of 13X molecular sieve is 20%. The first-stage pressure swing adsorption device includes adsorption, three-time pressure equalization, reverse discharge, flushing, three-time pressure equalization, and final filling process steps. The flushing gas is the partial desorptio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com