Coal consumption calculating method of composite firing low heat value gas unit

A technology of low calorific value gas and calculation method, which can be used in combustion methods, control combustion, lighting and heating equipment, etc., and can solve problems such as inability to carry out, complicated calculation of coal consumption, and numerous calculation parameters.

Inactive Publication Date: 2010-12-29

SHANGHAI JIAO TONG UNIV

View PDF0 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The conventional unit performance analysis of the power plant is carried out offline, using the data acquisition system (DCS) to collect data, based on the calculation method of the heat balance and mass balance of the unit, the main steps are the programming of the enthalpy and entropy charts, and the calculation of the extraction volume at all levels , heat consumption calculation and energy loss analysis, such analysis requires many calculation parameters, especially for gas-coal co-combustion units with low calorific value gas, the calculation of coal consumption is more complicated

When the sensors of these measuring points fail, the calculation results will have large deviations, and generally speaking, it will not be possible to perform

Therefore, the use of conventional calculation methods such as heat balance method has problems such as large amount of original data, complex calculation, and large error or impossibility in performance calculation when maintenance is improper, which is not suitable for online energy-saving and emission-reduction management.

[0003] Using the existing technical method to calculate the coal consumption of a unit requires 54 data measuring points (see Table 1). If the sensor of one of the measuring points is damaged, the calculation will not be possible. If hardware redundancy is set for the sensors of all measuring points, Resulting in increased hardware costs and higher costs

If the hardware redundancy is insufficient, once the sensor at the measuring point is damaged, the performance analysis system will not be able to operate normally, which will affect the evaluation of energy saving and emission reduction of the unit

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment approach

[0073] Implementation method of the present invention comprises:

[0074] Step 1. Raw data preparation

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

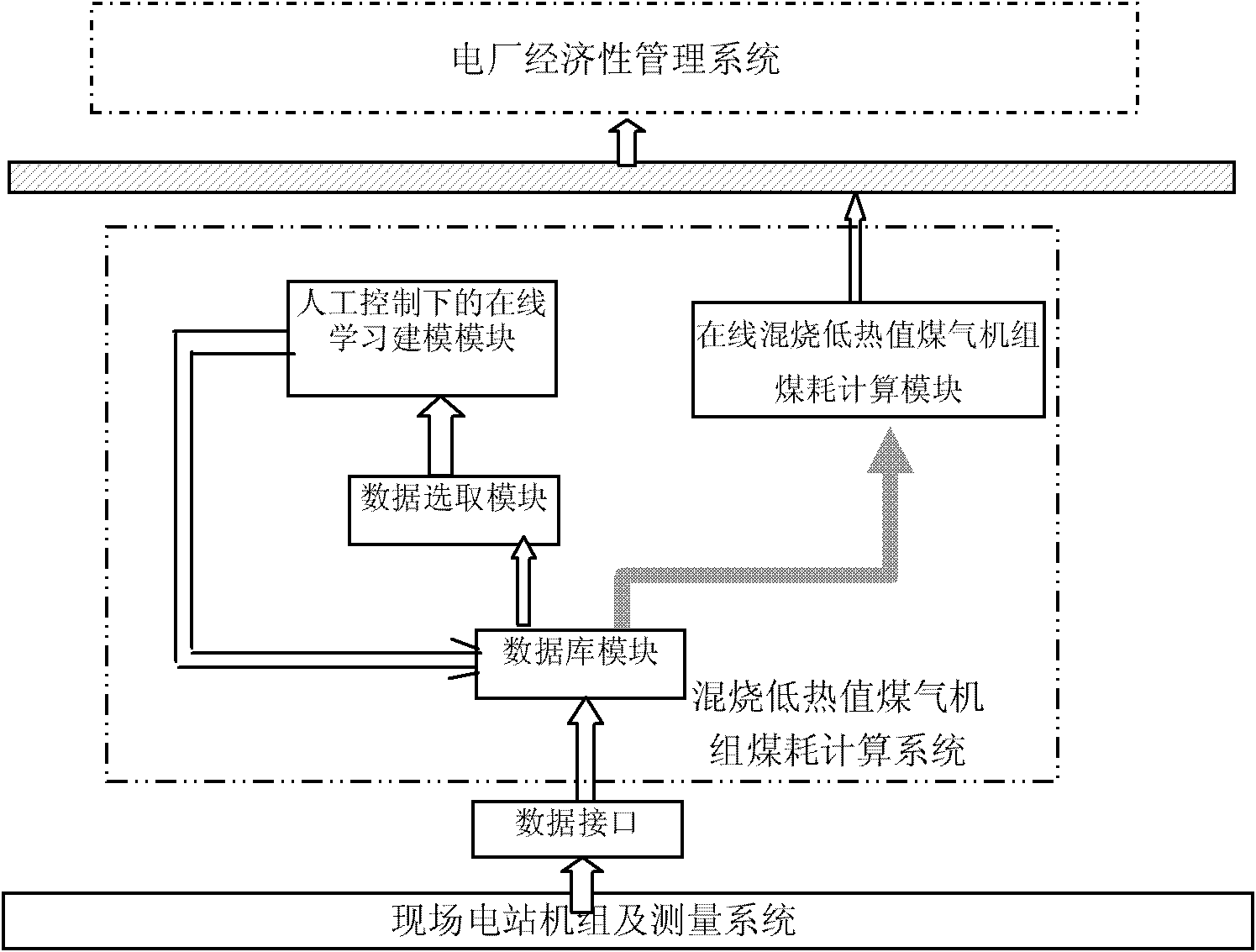

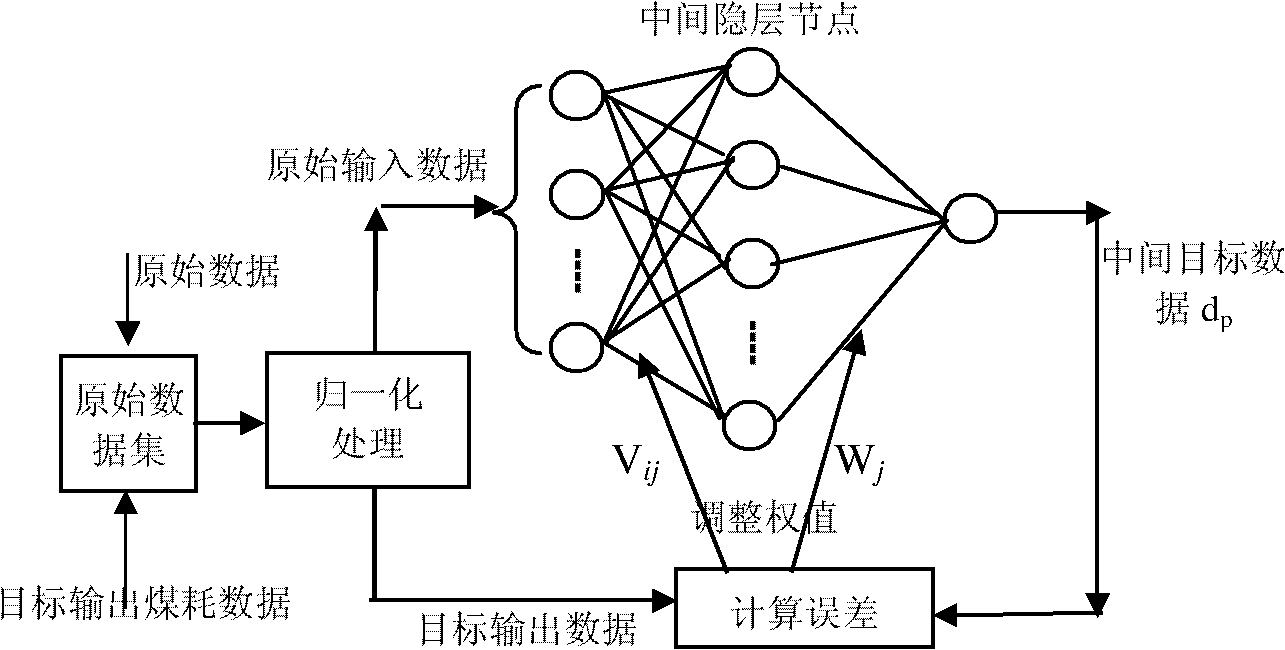

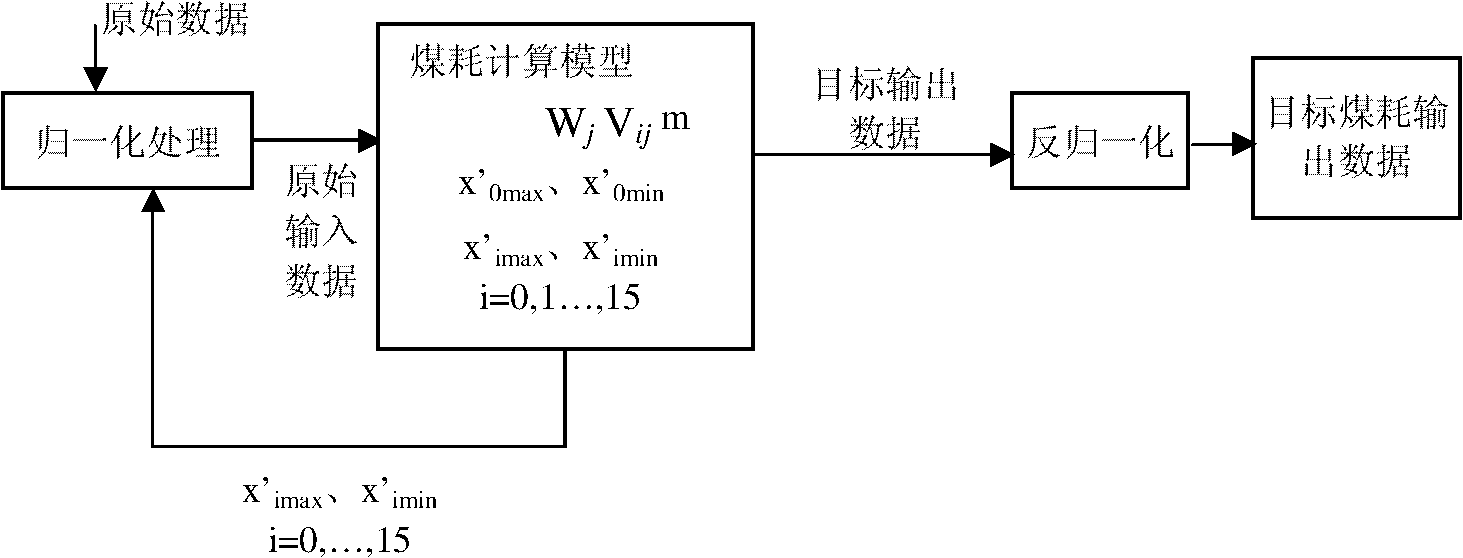

The invention relates to a coal consumption calculating method of a composite firing low heat value gas unit. A coal consumption calculating system of a composite firing low heat value gas unit is additionally arranged between a site power station unit and a management system used for measuring data acquired by the system and power station economy. The coal consumption calculating system comprises a database module, a manually controlled on-line learning modeling module and an on-line coal consumption calculating module of the composite firing low heat value gas unit. In the invention, a nonlinear mapping relation of input and output is established by only using an artificial neural network without using a complex enthalpy entropy chart calculating program and setting hardware redundancy on a measuring point sensor of all data, and higher-accuracy power generation coal consumption can be calculated on line.

Description

technical field [0001] The invention relates to a method for calculating the coal consumption of a co-fired low calorific value gas unit, in particular to a method for calculating the coal consumption of a large-scale power station unit co-fired with a low calorific value blast furnace gas unit, and belongs to the technical field of power station energy saving and consumption reduction. Background technique [0002] In recent years, the rising coal price and the requirement of energy saving and emission reduction have prompted power plants to carry out reforms to reduce energy consumption and improve economic efficiency. Therefore, high requirements have been put forward for power plant performance analysis. The conventional unit performance analysis of the power plant is carried out offline, using the data acquisition system (DCS) to collect data, based on the calculation method of the heat balance and mass balance of the unit, the main steps are the programming of the entha...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F23N1/00

Inventor 张东欧廖立杨昆蔡青杜光程苏明忻建华

Owner SHANGHAI JIAO TONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com