Flat-plate heat pipe

A flat heat pipe and plate technology, applied in indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of reduced condensation area, reduced heat transfer capacity, complex structure, etc., to reduce the generation of non-condensable gas, manufacture The effect of simple process and simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

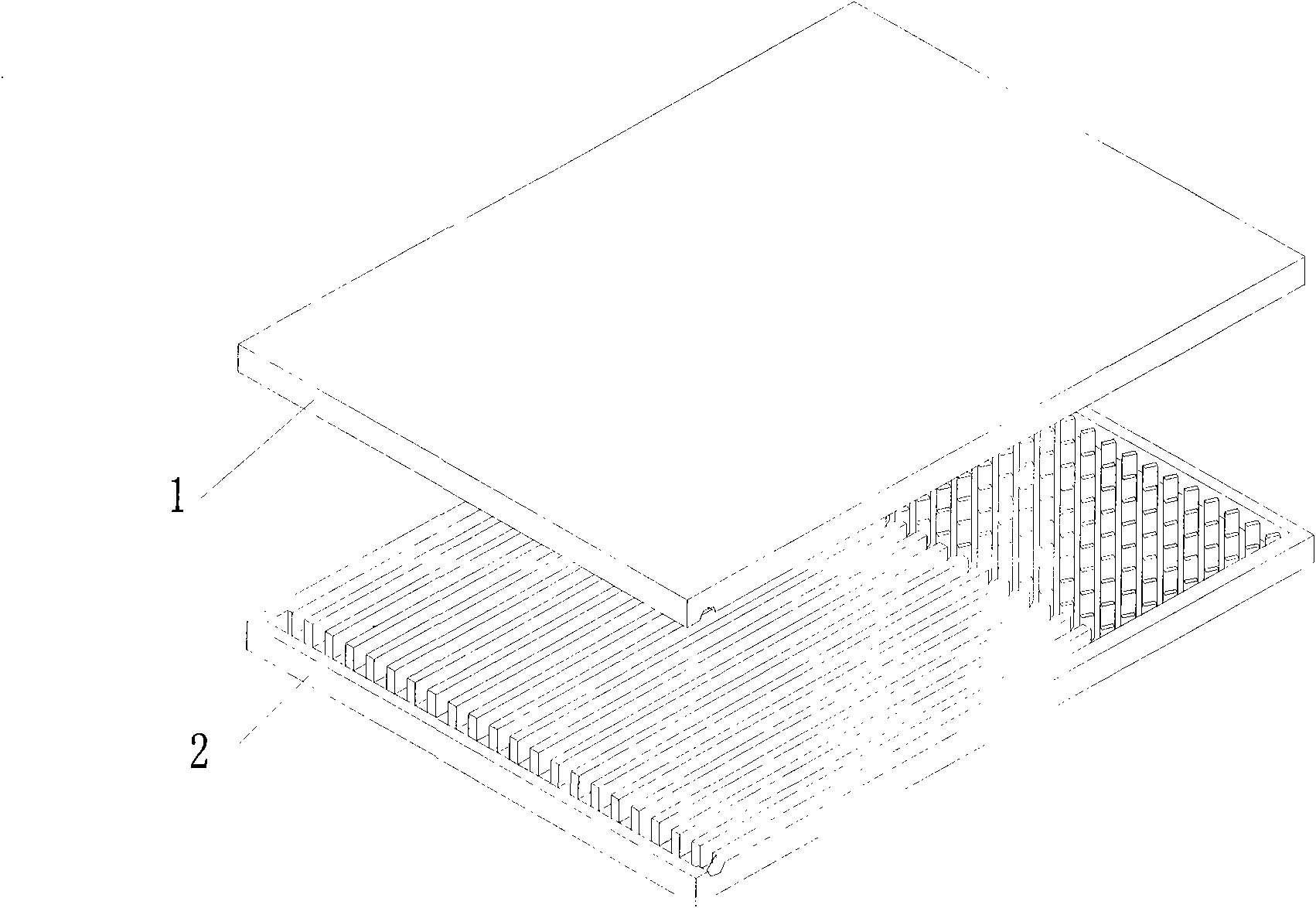

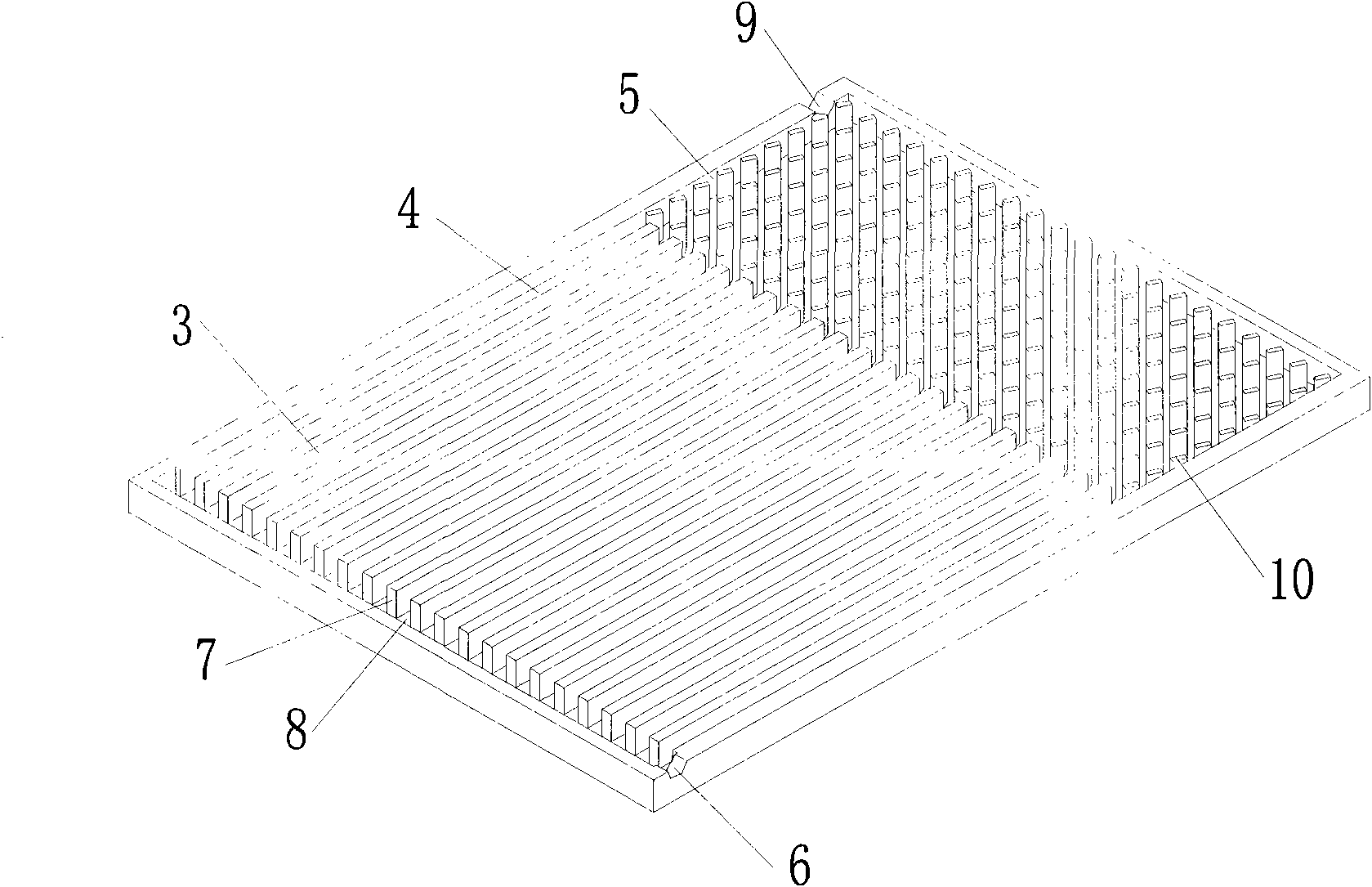

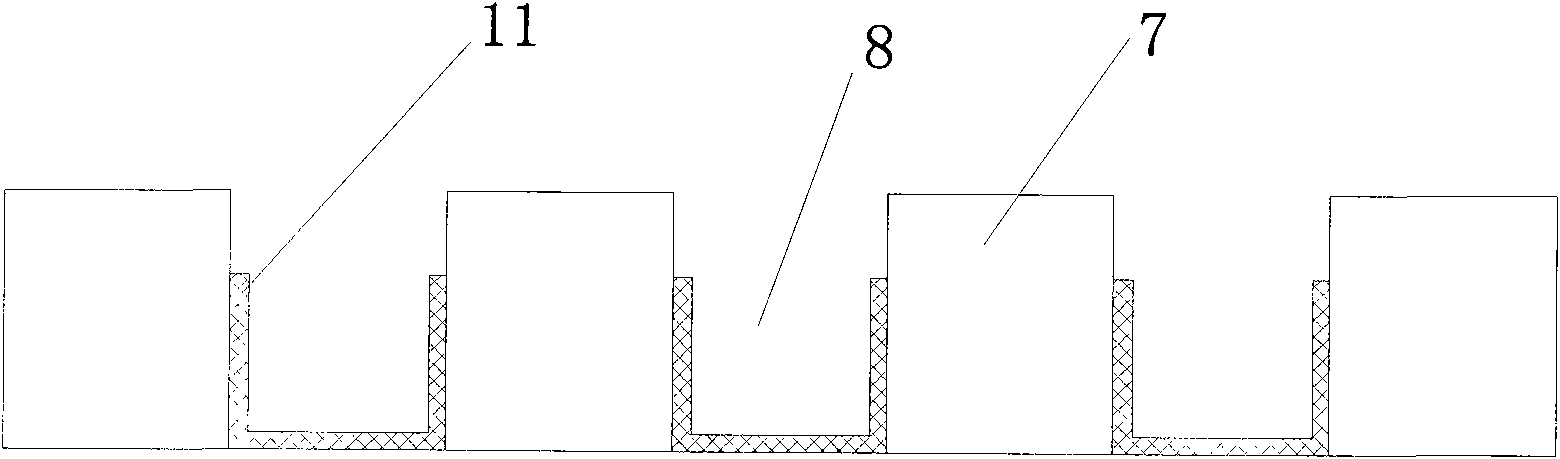

[0022] figure 1 An exploded view of the structure of the flat heat pipe of the present invention is given. The flat heat pipe of the present invention is formed by fastening the upper plate 1 and the lower plate 2 up and down. The materials of the upper plate 1 and the lower plate 2 are stainless steel, copper or high thermal conductivity materials such as aluminum. The connection methods used can be welding, clamping, bonding, etc., and the welding method is brazing, that is, using a filler metal with a melting point lower than the melting point of the base metal at a temperature lower than the melting point of the base metal and higher than the melting point of the solder , using liquid solder to wet and spread on the surface of the base metal and fill in the gap between the base metal, dissolve and diffuse with the base metal, and realize the welding of the connection between the parts. During welding, the solder melts but the base metal does not. The structures of the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com