Method for optimizing CMOS imaging sensor layout

An image sensor and layout technology, which is used in instrumentation, semiconductor/solid-state device manufacturing, special data processing applications, etc., can solve the problem of limiting the area of the active area of photodiodes, and achieve the effect of high fill factor and improved image quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

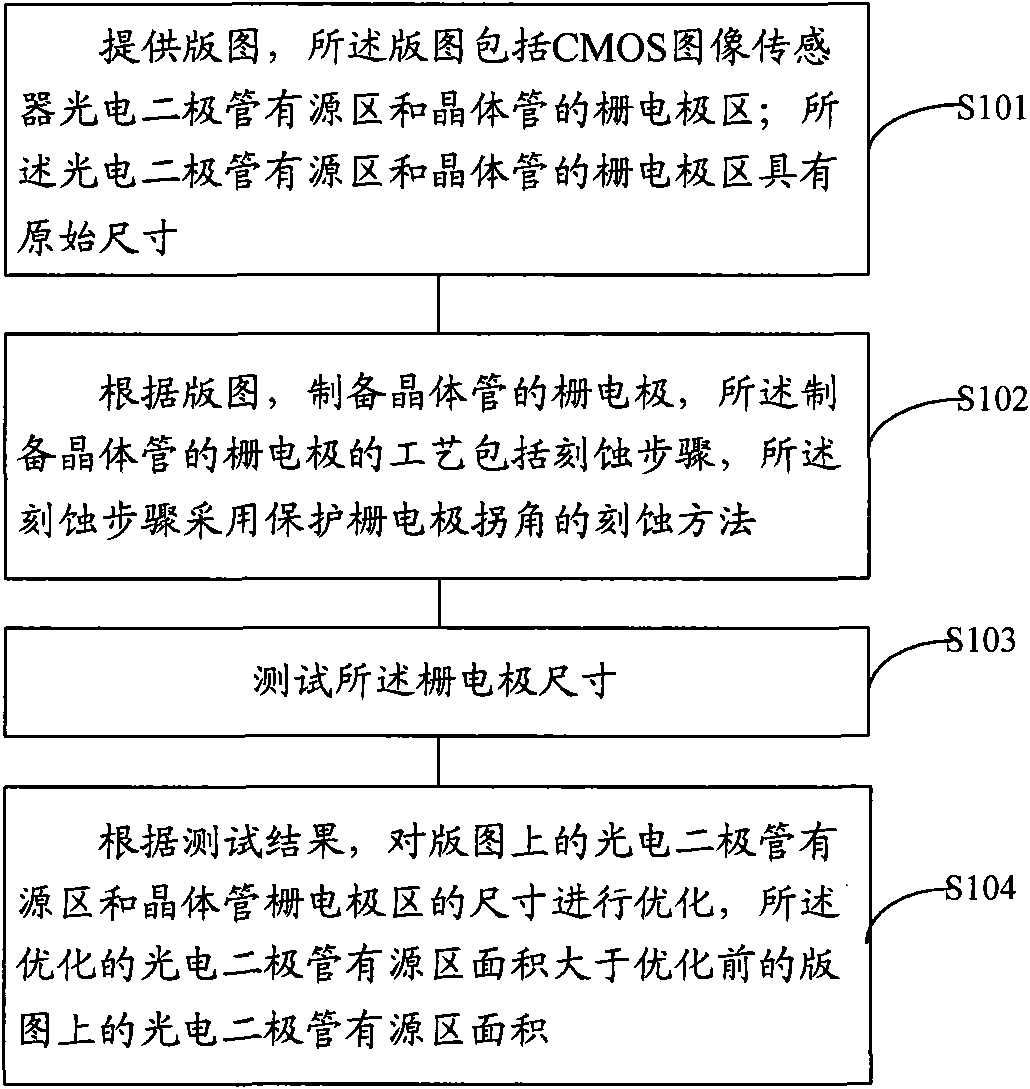

[0014] The present invention provides an embodiment of a method for optimizing the layout of a CMOS image sensor, such as image 3 shown, including the following steps:

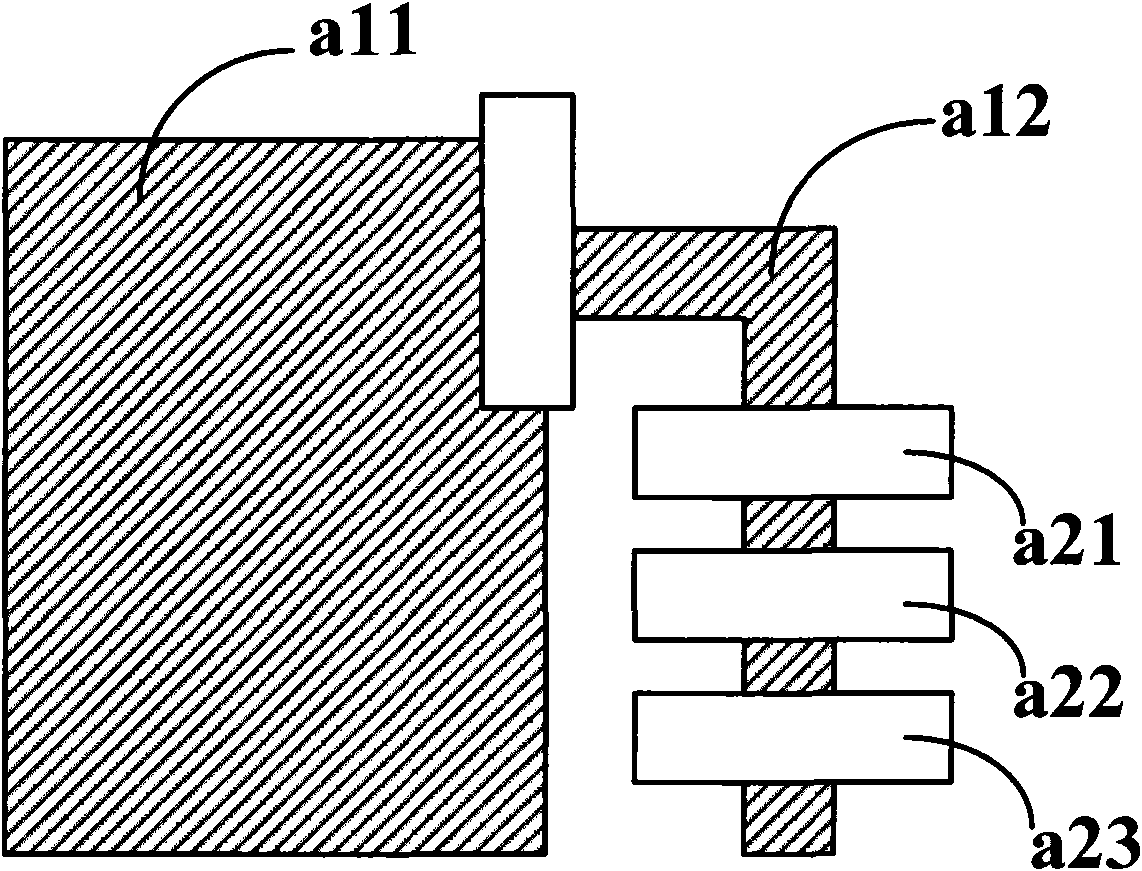

[0015] Step S101, providing a layout, the layout including the CMOS image sensor photodiode active area and the gate electrode area of the transistor; the photodiode active area and the transistor gate electrode area have original dimensions;

[0016] Step S102, preparing the gate electrode of the transistor according to the layout, the process of preparing the gate electrode of the transistor includes an etching step, and the etching step adopts an etching method for protecting the corner of the gate electrode;

[0017] Step S103, testing the size of the gate electrode;

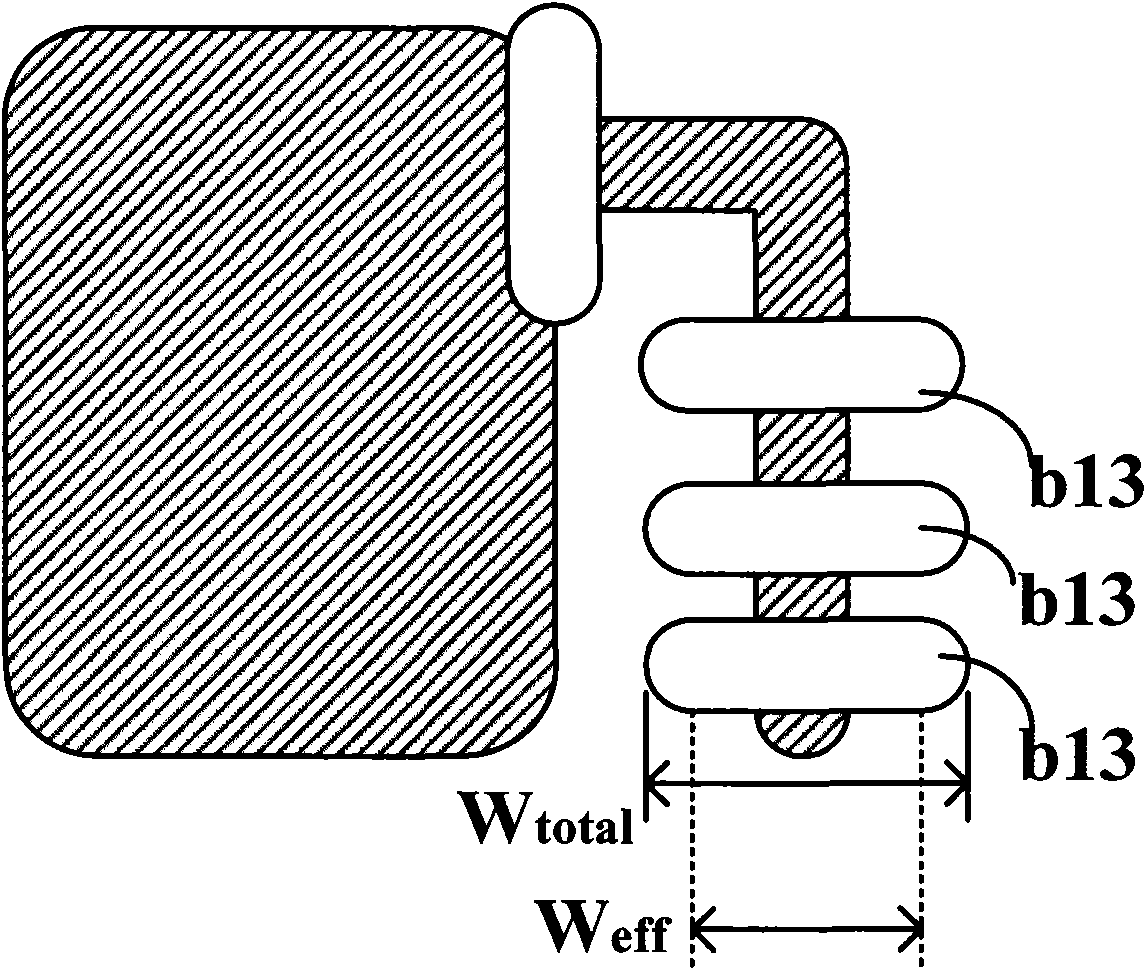

[0018] Step S104 , according to the test results, optimize the size of the photodiode active region and the gate electrode region of the transistor on the layout, and the optimized photodiode active region is larger than the photodiode a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com