Method for welding conical mill

A conical grinding and welding technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of roundness, straightness, and coaxiality of the grinding body, and achieve the effect of excellent manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] 1. Preparation

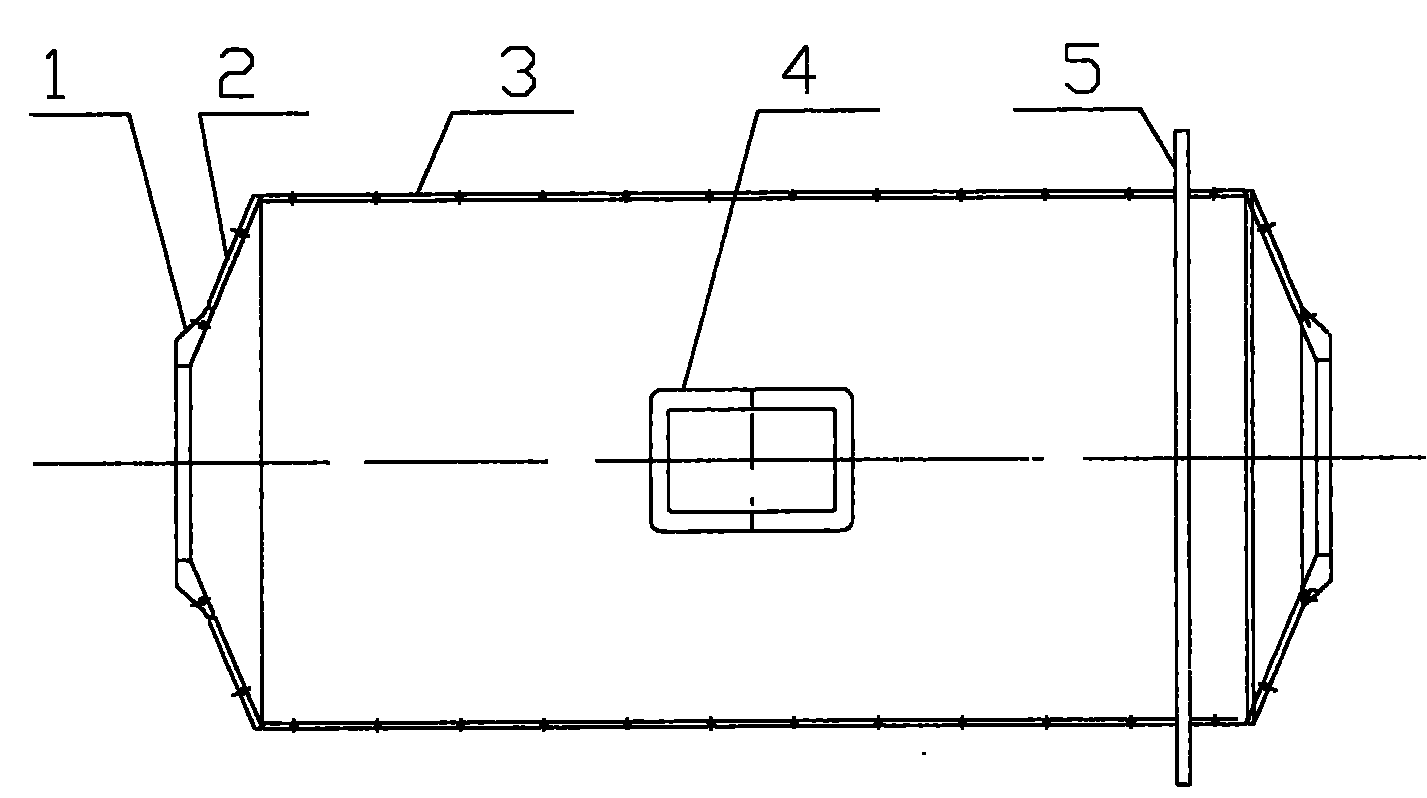

[0066] 1. If figure 2 shown in the size port 2

[0067] ①The material is cut in sections by numerical control. When the diameter of cylinder 3 is less than or equal to 2500mm, the material is divided into two parts, and when the diameter of the cylinder is larger than 2500mm, it is divided into four parts.

[0068] ②Regard the processing amount at the two ends of the large and small ports. When the diameter of the cylinder 3 is ≤2500mm, the processing amount of the large and small ports shall be 10mm and 5mm, respectively; when the diameter of the cylinder is larger than 2500mm, the processing amount shall be 15mm and 8mm respectively in the height direction of the large and small ports. quantity.

[0069] ③ Use a planer to plan an X-shaped material receiving groove.

[0070] 2. Cylinder 3

[0071] ①. In principle, only one longitudinal weld of each cylinder section is allowed, and the longitudinal circular seams of adjacent cylinder sections are st...

Embodiment 2

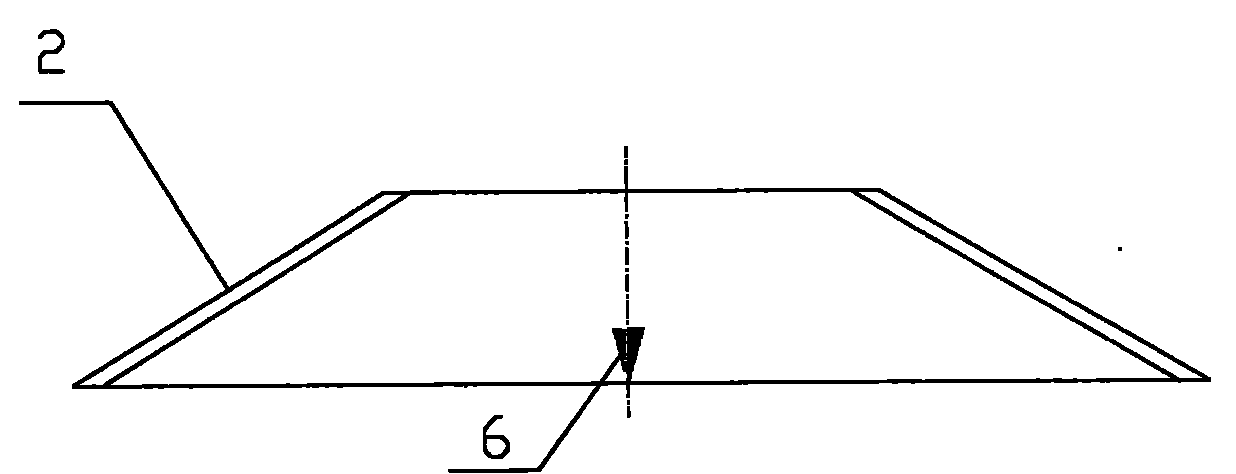

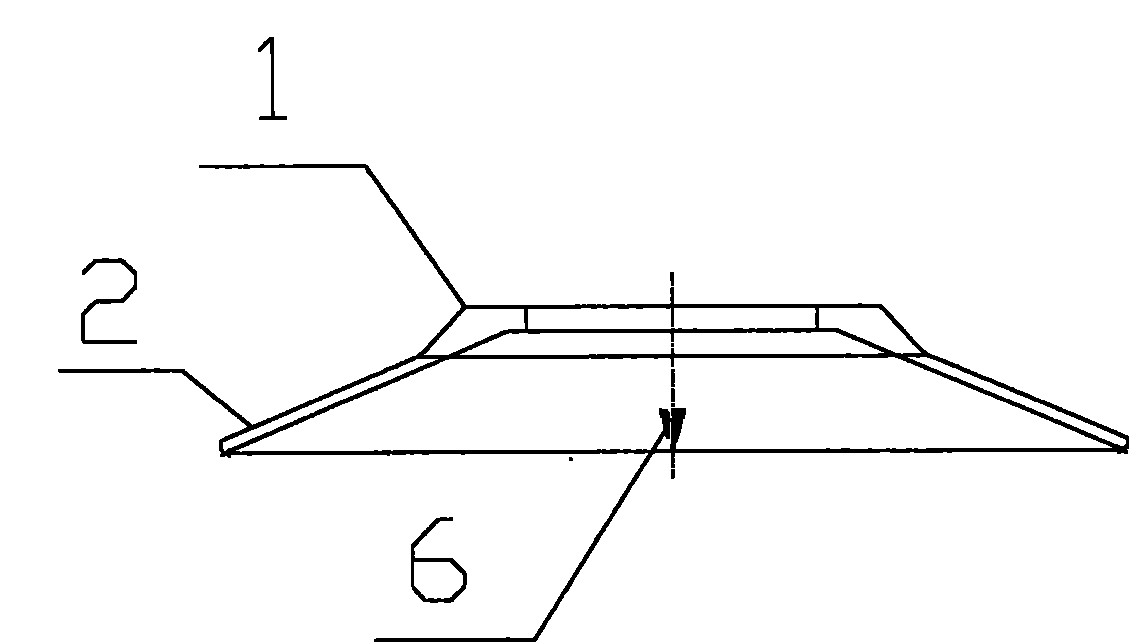

[0084] Such as image 3 , 4 as shown in

[0085] image 3 , 4 Among them, the ring 1 is a direct-supplied casting, and it participates in the assembly of the cone segment after rough machining.

[0086] ① Place the ground sample and hang the vertical line 6 to ensure that the concentricity of the part is 1mm and the roundness of the big mouth is 2mm, and at the same time, the height requirement after processing must be guaranteed.

[0087] ②Installing the process to support the processing, the dimensions to be guaranteed during processing:

[0088] a. Ensure that the upper end surface is machined to allow a margin of 10mm in the height direction (finally processed on the cylinder to the size of the drawing).

[0089] b. Ensure that the remaining inner diameter of the upper end ring 1 is not less than 20mm after processing (finally processed on the cylinder to the size of the drawing).

[0090] c.. During processing, process the large mouth to the size of the drawing, and...

Embodiment 3

[0100] Production of widgets I and II

[0101] ① press Figure 5 Assemble and weld the cone section (two pieces) and the cylinder straight section (two sections) respectively into small parts I and II (if the cylinder straight section is a section, only one of the cone sections is assembled with the cylinder straight section) Welded into small parts I).

[0102] ② When assembling the small parts I and II, place the ground sample and hang the vertical line 6 (vertical installation) to ensure that the concentricity of the small parts is 1 mm, and at the same time ensure the height requirements after processing. Note: 4 centerlines are marked on the cylinder, one of which passes through the manhole, and 4 centerlines are marked on the cone section by processing, and they are aligned according to the centerline during assembly.

[0103] ③When assembling, try to meet the requirements shown in "E" in Figure 5-1.

[0104] Mill overall assembly

[0105] ① After the small parts I a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Flatness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com