Crystal ceramic thick-film electric heating device and manufacturing method thereof

A thick film electric heating and device technology, applied in the direction of heating element materials, etc., can solve the problems of poor thermal shock performance, low insulation strength, heating device failure, etc., achieve good thermal shock performance, reduce equipment investment, and increase attachment. focus effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

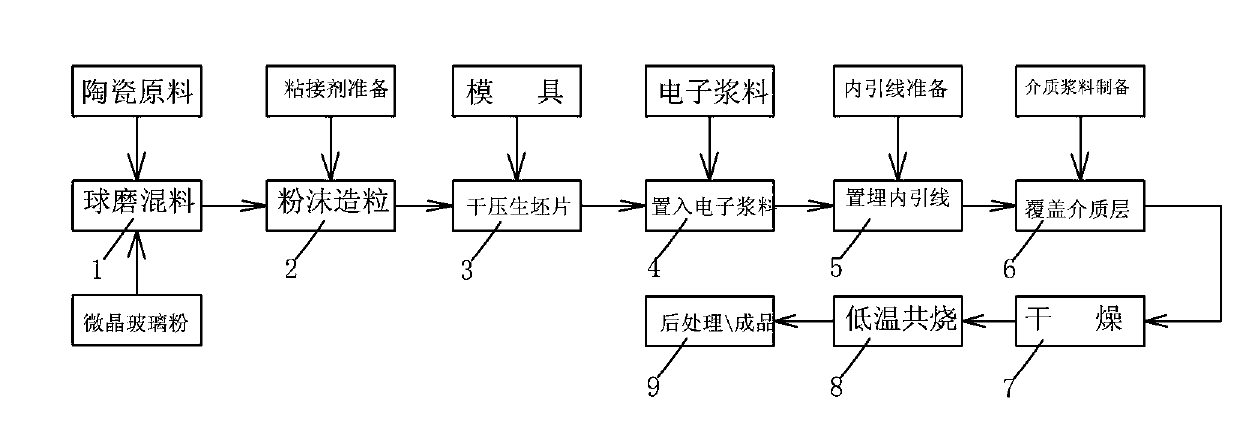

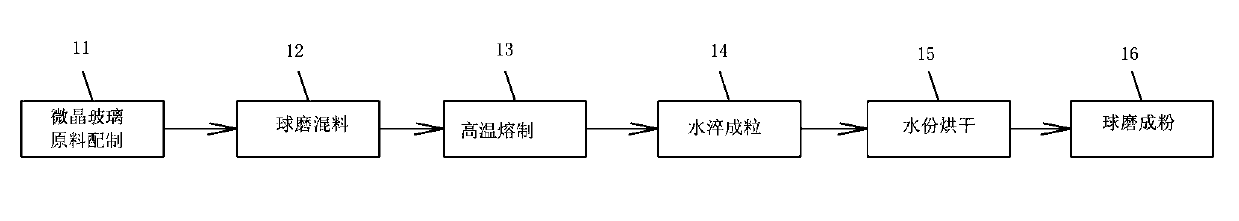

[0055] 1. Preparation of glass-ceramic powder

[0056] (11) Preparation of glass-ceramic raw materials, weighing each component according to the ratio described in 4 or 5;

[0057] (12) Ball mill mixing, use a ball mill to mix the various components evenly;

[0058] (13) High-temperature melting, melting the mixed raw materials at 1500-1700 degrees Celsius;

[0059] (14) Water quenching into granules, putting the melted glass-ceramics into water in a linear shape, so that the glass-ceramic liquid is cooled in water to form glass granules;

[0060] (15) Take out the glass grains, and dry the water on the surface of the glass grains at a temperature of 100-120 degrees Celsius;

[0061] (16) Ball mill into powder, put the dried glass particles into the ball mill, and ball mill to 300-1000 mesh for later use.

[0062] 2. Preparation of ceramic materials

[0063] (21) Preparation of ceramic materials, weighing each component according to the ratio described in 2 or 3;

[0064]...

Embodiment 3

[0132] Ceramic material 20 KG; glass-ceramic powder 80 KG;

[0133] Wherein, the ceramic material and glass-ceramic powder can be used in combination with any one of the above-mentioned ceramic materials 1-4 and glass-ceramic powder 1-4.

[0134] For example: 20 KG of ceramic material with 1 component of ceramic material and 80 KG of glass-ceramic powder with 1 component of glass-ceramic powder can be used together; it can also be 20 KG of ceramic material with 1 component of ceramic material and with Crystal glass powder 2, 3 or 4 components of glass-ceramic powder 80KG used together;

[0135] Of course, similarly, 20 KG of ceramic material with 2 components of ceramic material and 80 KG of glass-ceramic powder with 1, 2, 3 or 4 components of glass-ceramic powder can also be used together. Let me repeat.

Embodiment 4

[0137] Ceramic material 30 KG; glass-ceramic powder 70 KG;

[0138] Wherein, the ceramic material and glass-ceramic powder can be used in combination with any one of the above-mentioned ceramic materials 1-4 and glass-ceramic powder 1-4.

[0139] For example: 30KG of ceramic material with 1 component of ceramic material and 70KG of glass-ceramic powder with 1 component of glass-ceramic powder can be used together; it can also be 30 KG of ceramic material with 1 component of ceramic material and with Glass powder 2, 3 or 4 components of glass-ceramic powder 70KG used together;

[0140] Of course, similarly, 30KG of ceramic material with 2 components of ceramic material and 70KG of glass-ceramic powder with 1, 2, 3 or 4 components of glass-ceramic powder can also be used in combination, etc. In order to save space, no more repeat.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com