Acoustic insulation and absorption felt and production method thereof

A production method and technology for sound-absorbing felt, applied in the field of sound-absorbing sound-absorbing felt, can solve the problems of no sound absorption, poor stability, large shrinkage, etc., and achieve the effects of low thermal conductivity, low cost, and improved sound insulation function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

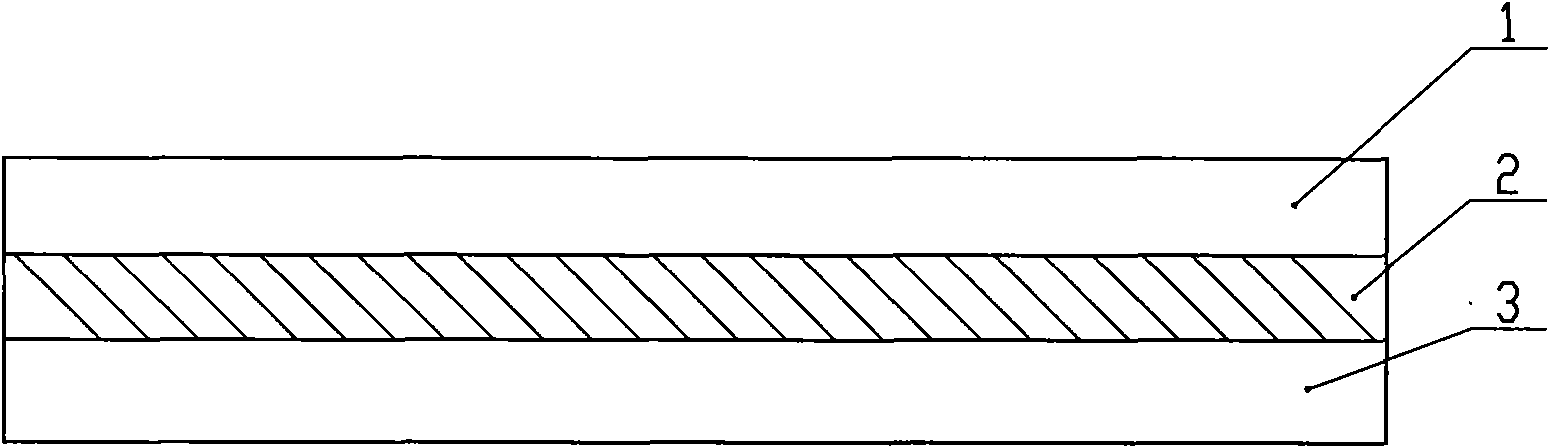

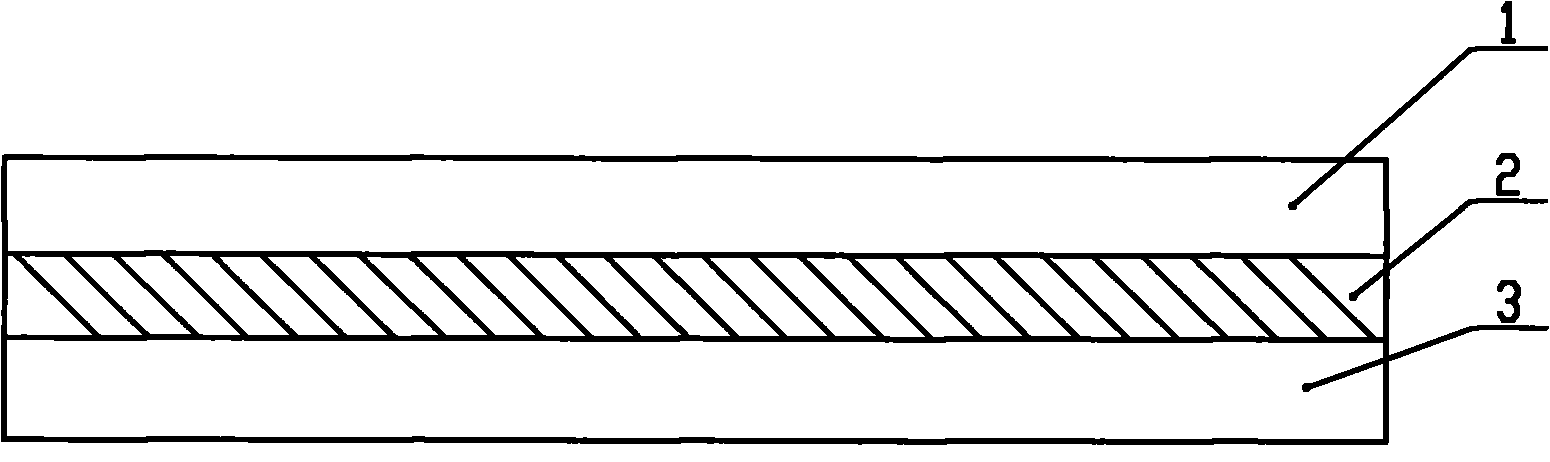

[0020] Such as figure 1 As shown, the present invention is a sound-insulating and sound-absorbing felt, comprising a surface layer 1 and a bottom layer 3, an adhesive layer 2 is arranged between the surface layer 1 and the bottom layer 3, and the materials of the surface layer 1 and the bottom layer 3 are modified polyester, The mixed fiber of waste cotton and polyester open wool, the surface layer 1 is a hard layer structure with dense and small gaps, the bottom layer 3 is a fluffy porous soft layer structure, and the material of the adhesive layer 2 is polyethylene, which is a film structure.

[0021] In the surface layer 1, the mass ratio of modified polyester, waste cotton and polyester open wool is (5-25): (15-45): (40-70); in the bottom layer 3, the modified The mass ratio of polyester, waste cotton and polyester opening wool is (20-5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com