Refining process of famotidine raw material

A technology for famotidine and raw materials, which is applied in the field of refining process of famotidine raw materials, can solve the problem of low famotidine yield and the like, and achieve the effects of high yield and simple process operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

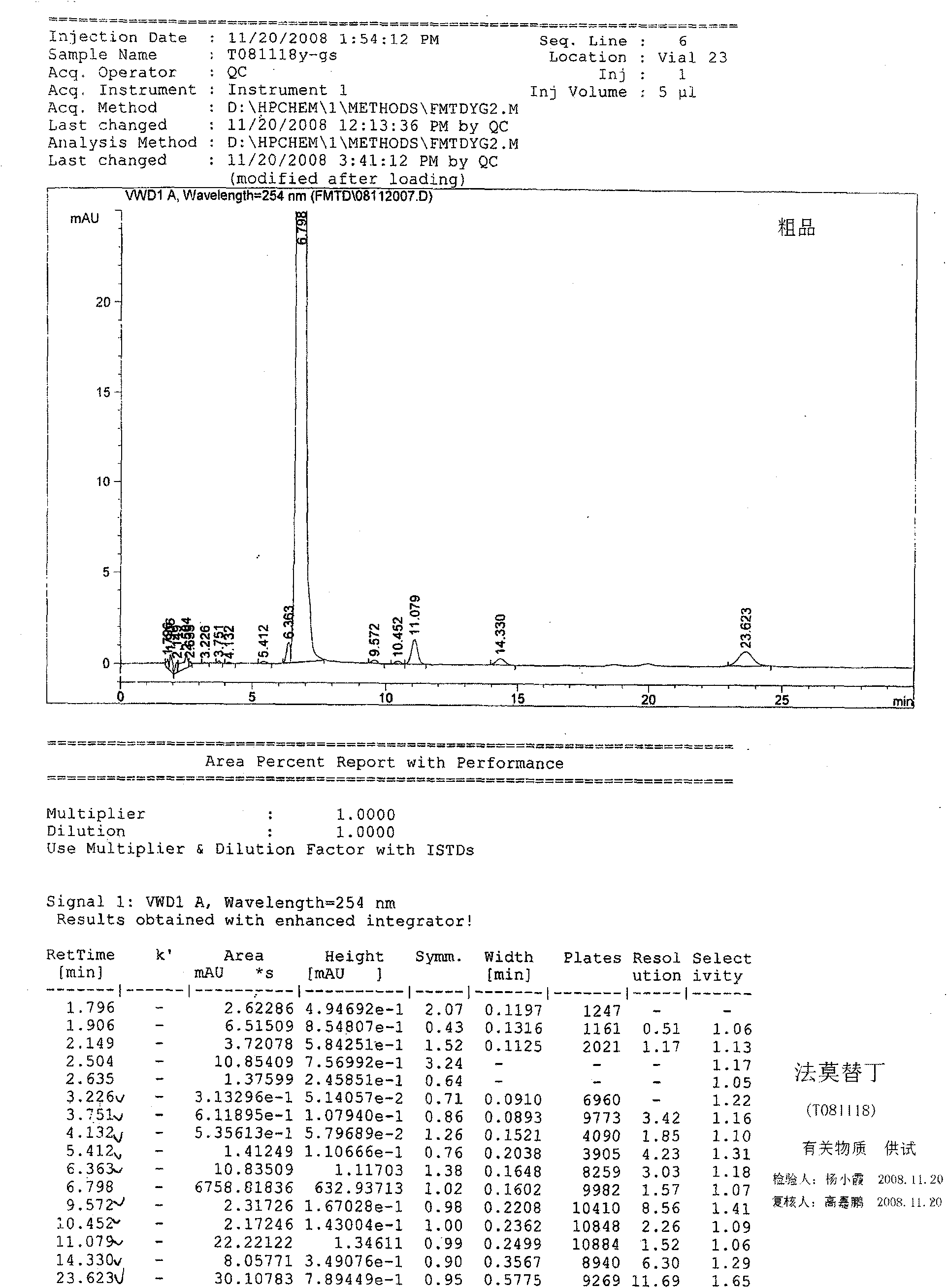

[0025] Embodiment 1: In this embodiment, the impurity content of the famotidine raw material with an impurity content of 1.2% is reduced to 0.5% through a refining process. The impurity content of famotidine crude product is 1.2% after testing, see figure 1 Liquid phase diagram of crude famotidine.

[0026] Feeding table for each material:

[0027] Material name

Feeding amount

Material ratio

Famotidine (crude product, impurity content 1.2%)

50.0g

1g

DMF (Dimethylformamide)

150mL

3mL

500mL

10mL

5g

0.1g

[0028] The specific operation steps are as follows:

[0029] 1) 500mL three-necked bottle neck, electric heating mantle, mechanical stirring, spherical condenser, constant pressure dropping funnel, 1000mL eggplant-shaped bottle;

[0030] 2) Add 150 mL of DMF (dimethylformamide), and 50.0 g of famotidine (crude product). Stir to completely dissolve the soli...

Embodiment 2

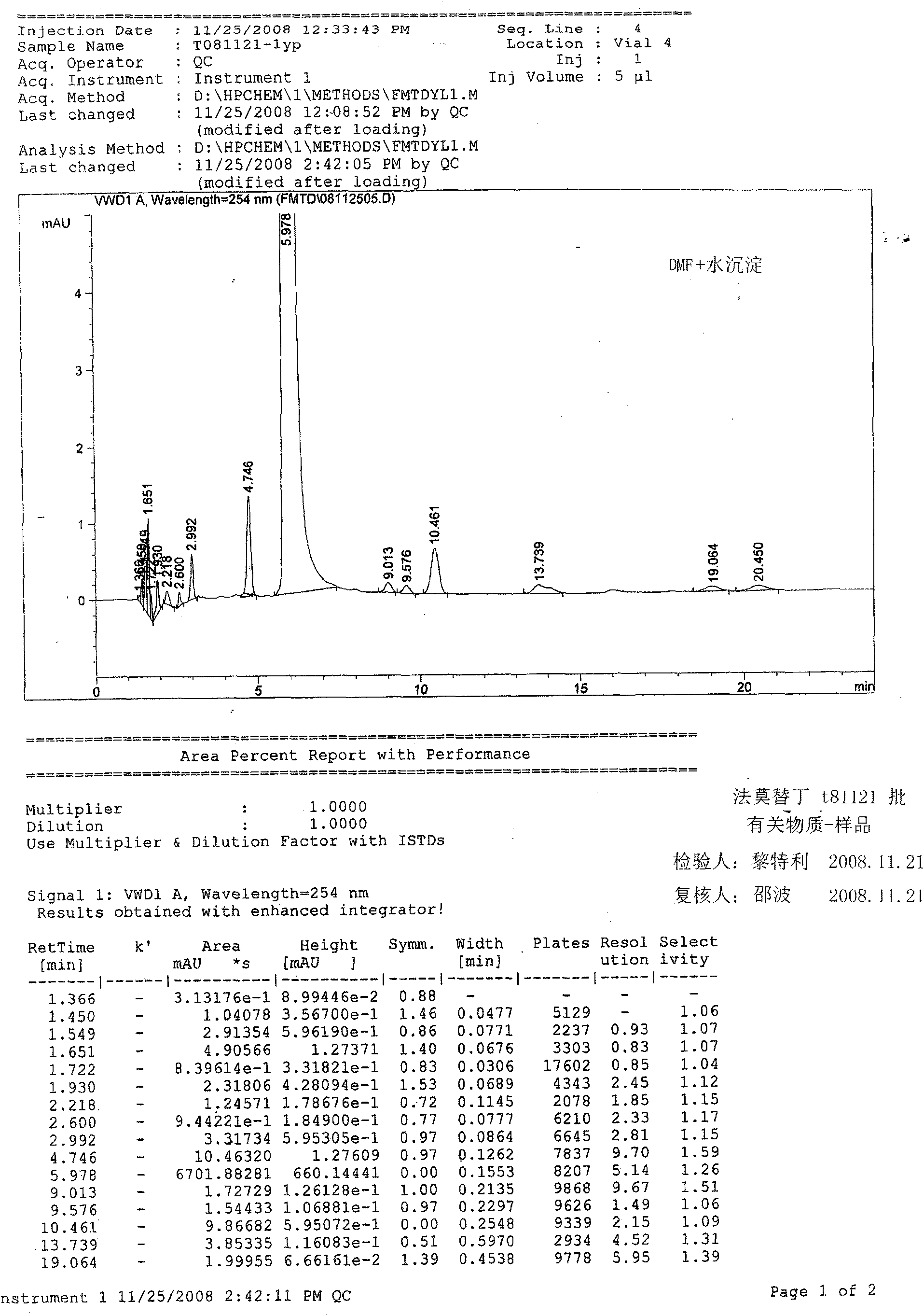

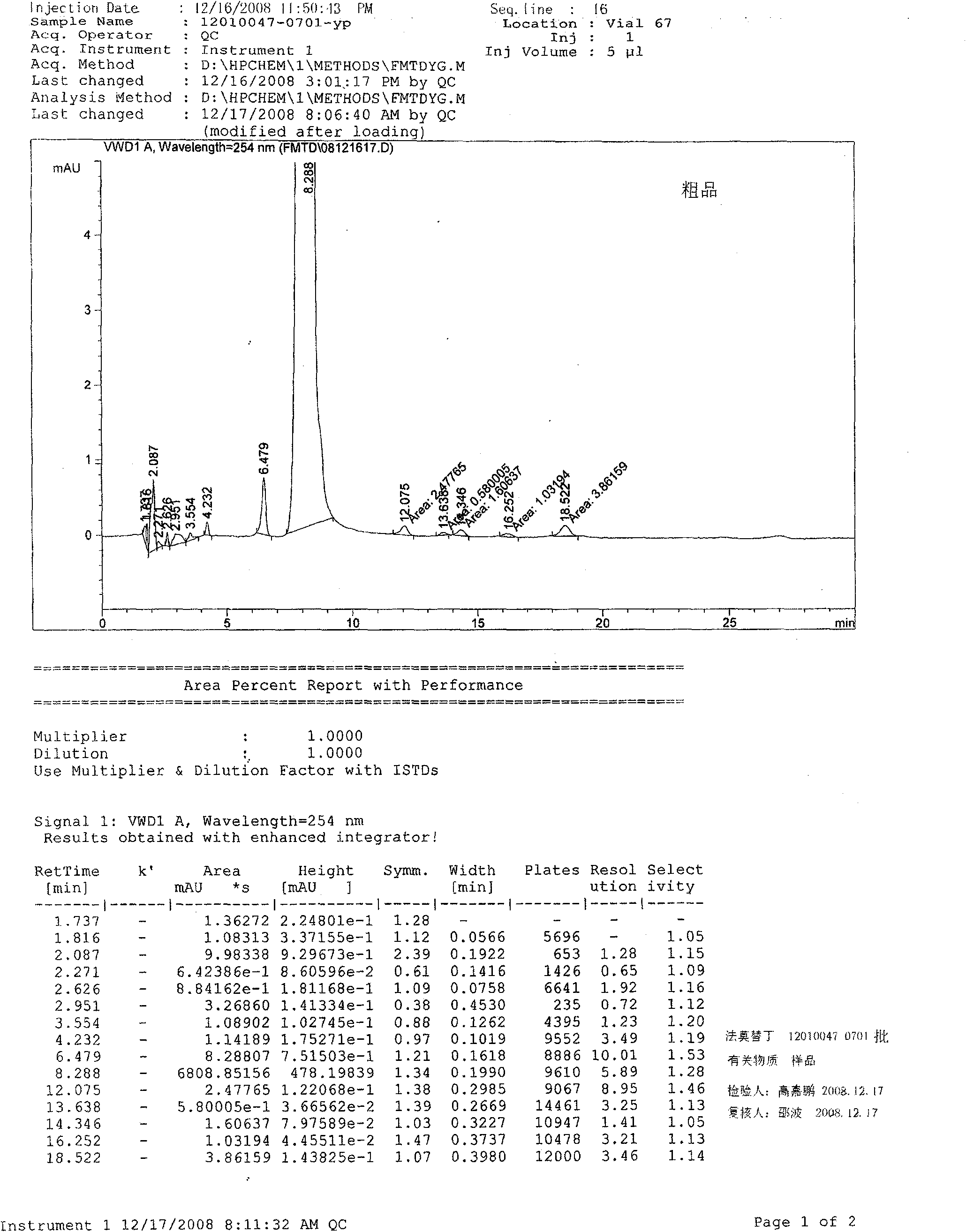

[0040] Embodiment 2: In this embodiment, the impurity content of the famotidine raw material with an impurity content of 0.3% is reduced to 0.1% through a refining process. The impurity content of famotidine crude product is 0.5% after testing, see image 3 Liquid phase diagram of crude famotidine.

[0041] The feed ratio table of each material in the present embodiment:

[0042] Material name

Feeding amount

Material ratio

Famotidine (crude product, impurity content 0.5%)

50.0g

1g

DMF (Dimethylformamide)

150mL

3mL

purified water

500mL

10mL

5g

0.1g

[0043] The operation steps of this implementation are as follows:

[0044] 1) 500mL three-necked bottle neck, electric heating mantle, mechanical stirring, spherical condenser, constant pressure dropping funnel, 1000mL eggplant-shaped bottle;

[0045] 2) Add DMF (dimethylformamide) 150mL, add famotidine (crude product) 50.0g...

Embodiment 3

[0054] Embodiment 3: the charging ratio of each material in the present embodiment is:

[0055] Material name

[0056] Concrete operation steps are identical with embodiment 1, and the yield of product is 83.9%, and impurity content will be 0.52% from 1.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com