Method for manufacturing synthetic resin, anion composite mat and manufacturing method thereof

A technology of synthetic resin and manufacturing method, applied in the direction of insulating layer, etc., can solve the problems of needing glue, difficulty in leveling, uncomfortable foot feeling, etc., and achieve the effect of meeting strength requirements and fast decoration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The anion composite ground mat of the present invention is described in further detail below by specific examples:

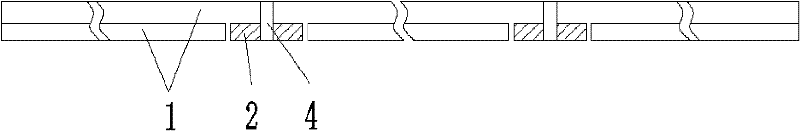

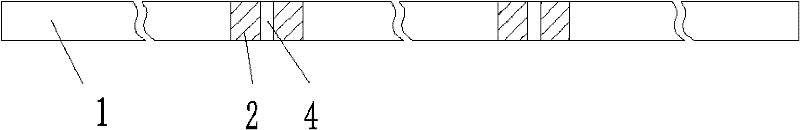

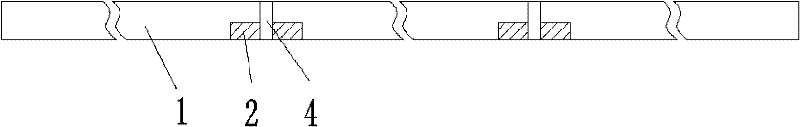

[0042] The negative ion composite ground mat of a preferred embodiment of the present invention comprises synthetic resin sheet material, and this synthetic resin sheet material adopts the low-pressure polyethylene sheet material through high-temperature foaming in this embodiment, wherein is evenly dispersed with tourmaline powder and activated carbon particle , the particle size of activated carbon particles is below 1500 μm in diameter. The negative ion composite floor mat also includes reinforcement boards 2 connected to the synthetic resin sheet at certain intervals and having a certain width. There are a series of through holes, and the reinforced version used in this embodiment is a wooden board, and of course it can also be an environmentally friendly material with certain strength and toughness such as a bamboo board. The synthetic resin sheet i...

Embodiment 2

[0047] The manufacture method of negative ion composite floor mat of the present invention is described in further detail below by specific examples:

[0048] First, the bamboo (or wood) material is processed into strip-shaped bamboo boards of 1200mm×40mm×5mm, and the negative ion synthetic resin sheet is processed into a sheet of 1200m×100m×4mm. Then, below the negative ion synthetic resin sheet, every 15cm bonding (bonding material can adopt hot-melt glue or cold glue etc.) a strip bamboo. Next, an anion synthetic resin sheet is bonded between adjacent strip-shaped bamboo boards to obtain an anion floor mat with a length of 100 m and a total thickness of 8 mm. Finally, a series of through holes are respectively opened in the middle of each strip-shaped bamboo board to facilitate installation.

[0049] In this embodiment, hot-melt adhesive, which has a fast bonding speed and is easier for industrial production, is used as the bonding material.

Embodiment 3

[0051] The manufacture method of negative ion synthetic resin of the present invention is described in further detail below by specific embodiment: at first, premix whipping agent monohepatic ester, particle size be tourmaline powder, blue organic toner, solid Spice rosin, sustained-release agent, particle size are about 13 μm (1000 orders) gac and synthetic resin particles, in the present embodiment, the weight ratio of described tourmaline powder in foaming material is 1% (certainly, can be in 0.5% ~5% for selection), the weight ratio of the activated carbon in the foamed material is 0.5%, and the weight ratio of the solid fragrance rosin in the foamed material is 0.01%. Then, at a high temperature of 130° and 2kg / cm 2 High-temperature foaming is carried out under pressure conditions; finally, the foamed synthetic resin is cooled by rapid water cooling with tap circulating water at 0°-50° to obtain a blue negative ion foaming material, that is, negative ion synthetic resin. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com