Low-emission diesel engine lubricating oil composite

A kind of lubricating oil composition, technology of diesel engine, applied in the field of lubricating oil

Active Publication Date: 2013-04-24

PETROCHINA CO LTD

View PDF9 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0014] However, there is no patent disclosure about the use of hydrogenated base oil to prepare to meet the requirements of API CI-4+ diesel engine oil specifications, and at the same time limit the sulfur, phosphorus and sulfate ash content of the oil to meet the requirements of lubrication with exhaust gas after-treatment systems. oil composition

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0066] A full-component 10W-40CI-4+ diesel engine oil was prepared. The formula composition and the data obtained therefrom are listed in Table 1.

[0067] Table 1

[0068]

[0069] It can be seen from Table 1 that the 10W-40CI-4+ low-sulfur, low-phosphorus, low-ash diesel engine oil prepared has excellent anti-oxidation, anti-wear and soot dispersion properties, and excellent high-temperature detergency.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

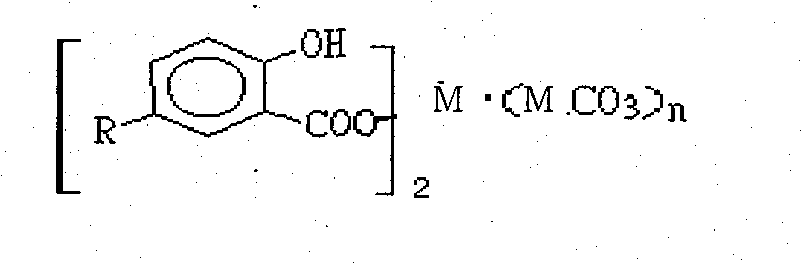

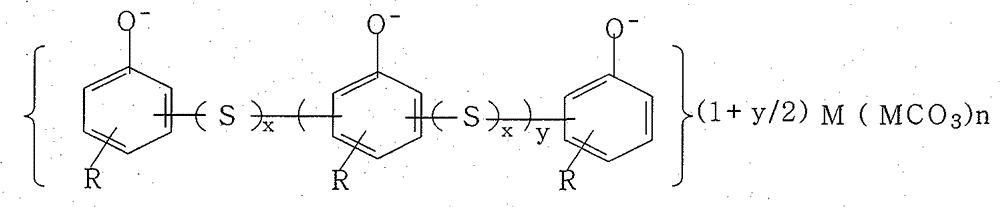

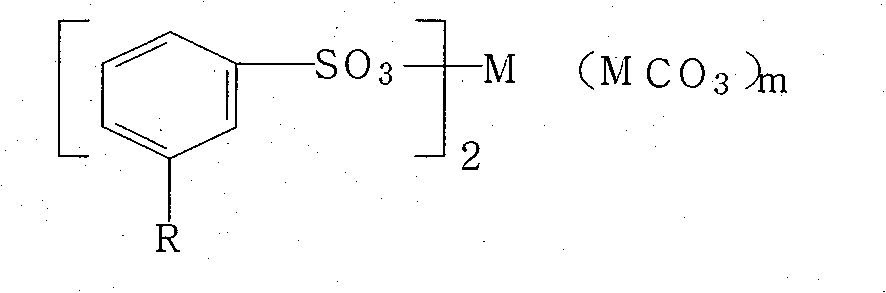

The invention discloses a composite comprising a great quantity of hydrotreating base oil, a proper quantity of alkylsalicylate, vulcanizing alkyl phenate, sulfonate, macromolecule ashless dispersant, polyisobutene bissuccinimide ashless dispersant, polyisobutene monosuccinimide ashless dispersant, boronizing polyisobutenyl bissuccinimide ashless dispersant, zinc dialkyl dithiophosphate, phenolictype antioxygen, amine type antioxygen, sulphur-containing antioxidizing anti-wear agent and ashless dithiophosphate extreme pressure antiwear additive. The lubricating oil composite of the invention is used for lubricating the heavy-load diesel engines containing reprocessing facilities, such as oxidation catalyst (DOC), particulate filters or trap (DPF), selective reduction catalyst (SCR), oxynitride trap (LNT) and the like. The invention can satisfy the specification requirements of API CI-4+ diesel engine oil, and has lower sulphur, phosphorus and sulfate ash content so as to avoid adverse impact on the reprocessing facilities.

Description

(1) Technical field [0001] The present invention relates to an engine lubricating oil composition, and in particular to a type for use with an oxidation catalyst (DOC), a particulate filter or trap (DPF), a selective reduction catalyst (SCR), and a nitrogen oxide compound trap Lubricating oil composition for low-emission, heavy-duty diesel engines in after-treatment facilities such as LNT. It belongs to the technical field of lubricants. (2) Background technology [0002] Environmental protection, energy saving, and extended oil change intervals are the main driving forces for the improvement of oil specifications. With the continuous strict foreign emission regulations, engine manufacturers adopt various new technologies, such as oxidation catalyst (DOC), particulate filter or trapping After treatment technology such as DPF, selective reduction catalyst (SCR), nitrogen oxide trap (LNT), exhaust gas recirculation (EGR), etc., to enable its engines to meet increasingly stringent ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C10M161/00C10M141/10C10N30/12C10N30/10C10N30/06C10N30/04C10N30/02C10N40/25

Inventor 孙丁伟汤仲平金鹏张勤赵正华荆海东

Owner PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com