Steel with high strength, low-temperature impact resistance and weatherability for wind-powered pivoting support and production process thereof

A technology of slewing bearing and production process, applied in the field of alloy structural steel, to achieve excellent performance, low yield ratio, and improve the effect of low temperature impact energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

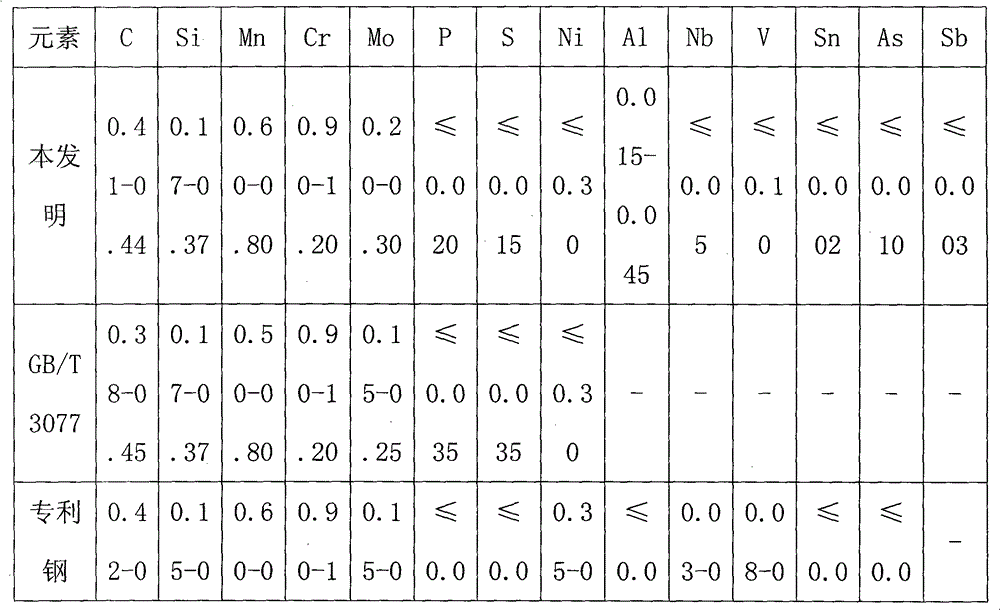

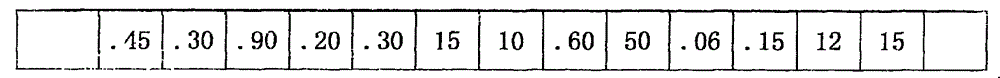

Method used

Image

Examples

Embodiment 1

[0032] Prepared by the following production process:

[0033] (1) Converter smelting, smelting in a top-bottom double-blowing converter of more than 60 tons, adding molten iron and scrap steel, the converter realizes pre-de-P, retaining slag and leaving slag to prevent re-P, tapping for pre-deoxidation alloying and composition initial tune;

[0034] (2) LF refining, making high-basic slag desulphurization and deoxygenation in an LF furnace of more than 60 tons, sufficient soft blowing time and argon blowing intensity to ensure the effect of removing inclusions;

[0035] (3) RH, after LF refining, can also be used before LF refining, use more than 60 tons of RH, keep it under high vacuum for more than 25 minutes, realize vacuum degassing and remove inclusions, and ensure that [H]≤0.00015%, [O]≤0.0015% to obtain higher cleanliness of molten steel;

[0036] (4) Continuous casting, using the R14m 6-machine 6-strand continuous casting machine produced by Danieli in Italy. During ...

Embodiment 2

[0042] C 0.42%, Si 0.26%, Mn 0.68%, Cr 1.02%, Ni0.01%, Mo 0.23%, V 0.005%, Nb 0.002%, Al 0.036%, S 0.001%, P 0.011%, B 0.0003%, Cu 0.01%, Sb 0.0003%, Sn 0.0012%, As 0.003%, [O] 0.0010%, [N] 0.0048%, [H] 0.00010%, the rest is Fe.

[0043] After the φ500m round billet is forged and processed, the V-notch impact energy AKv=6J at -40°C.

[0044] All the other implementations are as in Example 1.

Embodiment 3

[0046] C 0.43%, Si 0.27%, Mn 0.69%, Cr 1.01%, Ni 0.02%, Mo 0.24%, V 0.004%, Nb 0.002%, Al 0.034%, S 0.001%, P 0.011%, B 0.0003%, Cu 0.01 %, Sb 0.0003%, Sn 0.0012%, As 0.003%, [O] 0.0011%, [N] 0.0043%, [H] 0.00012%, and the rest is Fe.

[0047] After the φ500mm round billet is forged and processed, the V-notch impact energy AKv=56J at -40°C.

[0048] All the other implementations are as in Example 1.

[0049] The Ni, V, and Nb elements in the above three embodiments are brought in by steel scrap. The present invention limits the Ni, V, and Nb brought in by steel scrap, wherein Ni≤0.30%, V≤0.10%, and ≤0.05%.

[0050] For the steels obtained in the above three examples, after the round billets are forged and processed, the low-temperature impact energy measured is the performance index of the actual products used by Xuzhou Rothe Erde Slewing Bearing Co., Ltd.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com