Preparation method of additive for electrolytic copper foil, product and application thereof

An electrolytic copper foil and additive technology, which is applied in the electrolytic process, electroforming and other directions, can solve the problems of failing to meet, reduce the roughness of the electrolytic copper matte surface, and increase the density of crystal grains, so as to reduce the roughness of the matte surface, reduce The effect of increasing crystal density and increasing tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

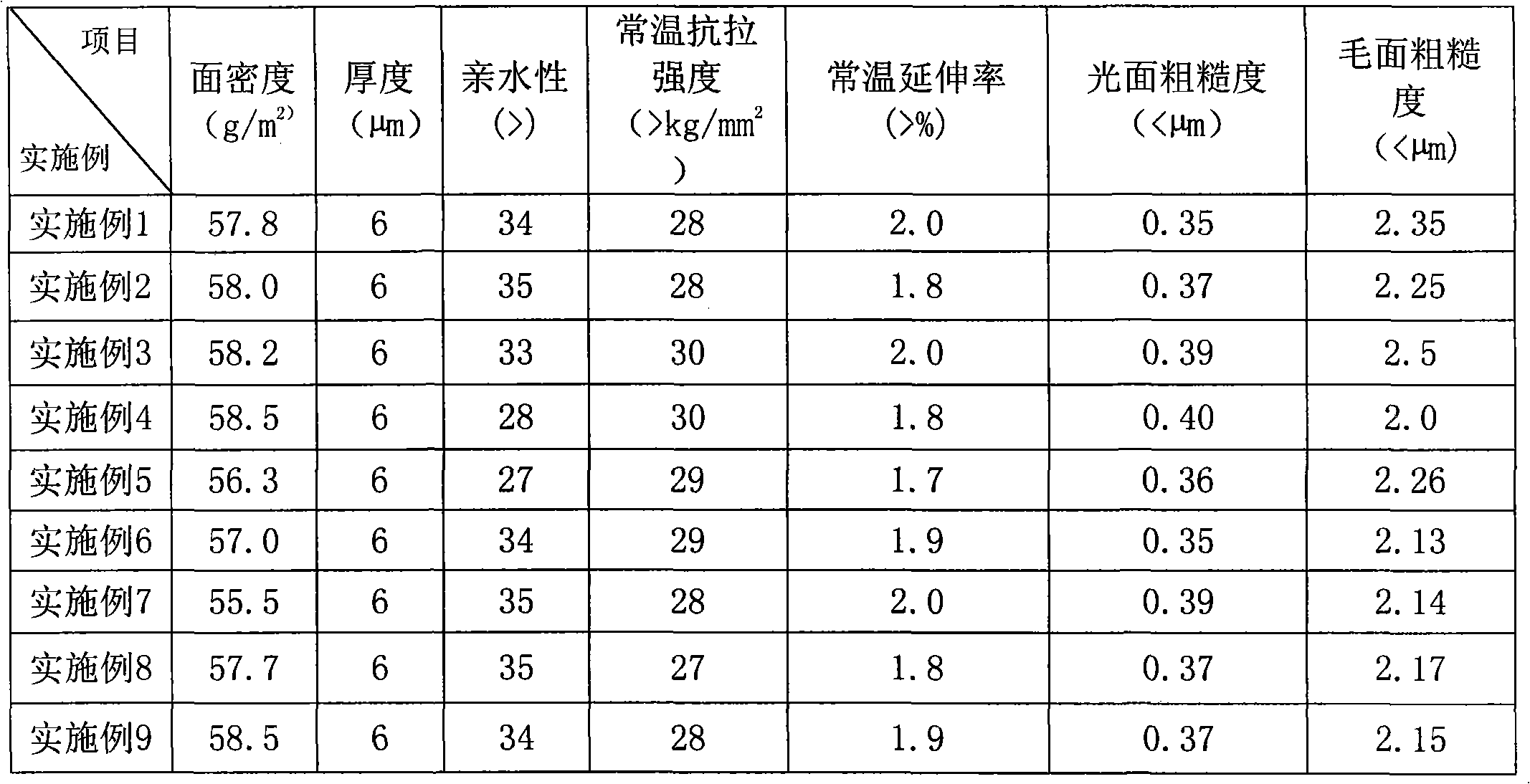

Examples

Embodiment 1

[0030] A method for preparing an additive for electrolytic copper foil provided by the invention comprises the following process steps:

[0031] (1) Weighing: Weigh 100mg thiourea, 500mg polyethylene glycol, 50mg 3-(benzothiazole-2-mercapto)-propanesulfonate sodium, 100mg gloss additive;

[0032] (2) Dissolving: Add the weighed thiourea, polyethylene glycol, 3-(benzothiazole-2-mercapto)-propanesulfonate sodium, The gloss additive was heated at a constant temperature of 45°C, stirred for 60 minutes, and fully dissolved to obtain a mixed solution;

[0033] (3) Dilution: dilute the mixed liquid in step (2) to 10 L with water to obtain an additive for electrolytic copper foil.

[0034] The gloss additive is a fluorocarbon surfactant, specifically: anionic, cationic, nonionic, and amphoteric fluorocarbon surfactants. In this embodiment, an ethoxylated nonionic fluorocarbon surfactant is selected.

Embodiment 2

[0036] (1) Weighing: Weigh 200mg thiourea, 1000mg polyethylene glycol, 100mg 3-(benzothiazole-2-mercapto)-propanesulfonate sodium, 200mg nonionic fluorocarbon surfactant;

[0037] (2) Dissolving: Add the weighed thiourea, polyethylene glycol, 3-(benzothiazole-2-mercapto)-propanesulfonate sodium, The non-ionic fluorocarbon surfactant was heated at a constant temperature of 45°C, stirred for 60 minutes, and fully dissolved to obtain a mixed solution;

[0038] (3) Dilution: dilute the mixed liquid in step (2) to 10 L with water to obtain an additive for electrolytic copper foil.

Embodiment 3

[0040] (1) Weighing: Weigh 300mg thiourea, 1500mg polyethylene glycol, 150mg 3-(benzothiazole-2-mercapto)-sodium propanesulfonate, 300mg nonionic fluorocarbon surfactant;

[0041] (2) Dissolving: Add the weighed thiourea, polyethylene glycol, 3-(benzothiazole-2-mercapto)-propanesulfonate sodium, The non-ionic fluorocarbon surfactant was heated at a constant temperature of 45°C, stirred for 60 minutes, and fully dissolved to obtain a mixed solution;

[0042] (3) Dilution: dilute the mixed liquid in step (2) to 10 L with water to obtain an additive for electrolytic copper foil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com