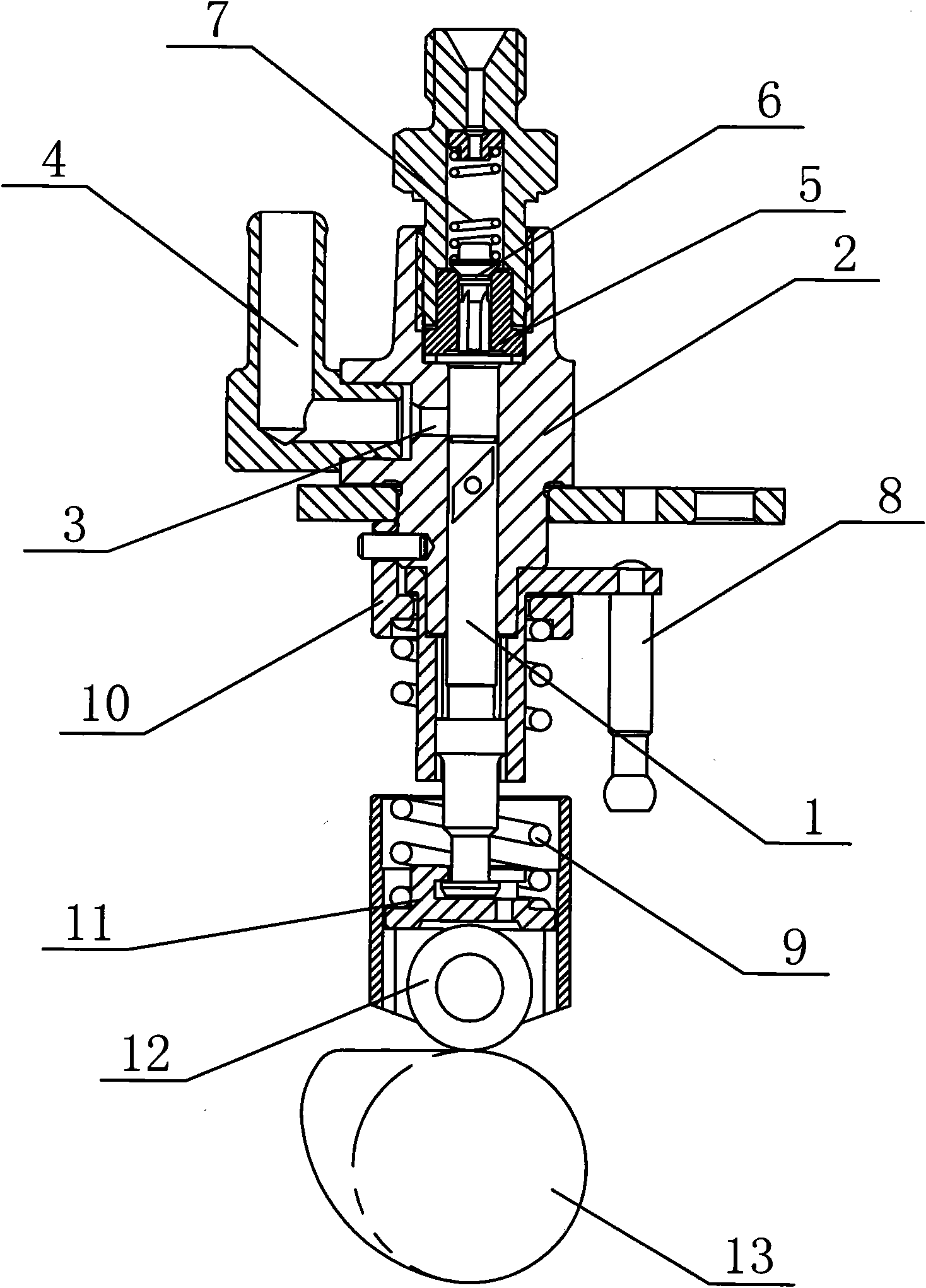

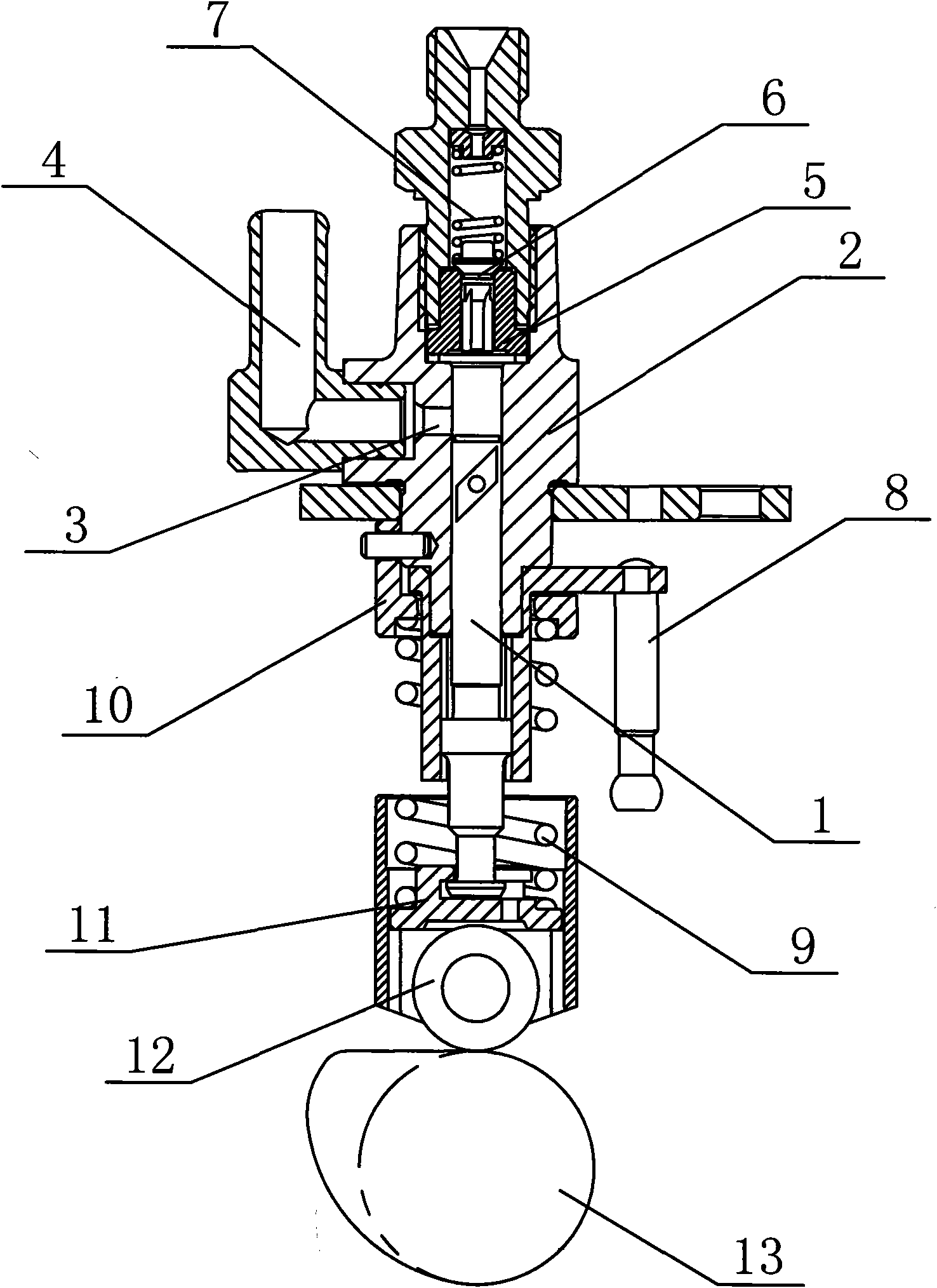

Oil feeder of single-cylinder air-cooling diesel engine

A fuel supply device and diesel engine technology, which is applied to valve devices, fuel injection devices, charging systems, etc., can solve the problems of high hydrocarbon and carbon monoxide emissions, poor combustion effect of diesel engines, and long duration, so as to improve the combustion effect. , The effect of shortening the duration of fuel supply and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] see figure 1 as shown, figure 1 It is a structural schematic diagram of a single-cylinder air-cooled diesel engine oil supply device of the present invention. In this embodiment, a single-cylinder air-cooled diesel engine oil supply device includes a fuel injection pump and a matching oil supply cam 13. The oil supply cam 13 is a compound function cam, the fuel injection pump includes a plunger 1, the plunger 1 communicates with the oil inlet pipe 4 through the oil inlet hole 3, and the plunger pair 2 is equipped with the plunger 1, and the plunger 1 One end of the oil outlet valve core 6 is provided with an oil outlet valve spring 7, and the oil outlet valve core 6 is equipped with an oil outlet valve coupler 5, and the other end of the plunger 1 A plunger spring 9 is provided, and the plunger spring 9 is assembled on the plunger 1 through a plunger spring support body 10 and a plunger spring base 11. A roller tappet 12 is provided on one side, and an oil volume cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com