Seawater source heat pump system

A source heat pump, seawater technology, applied in the energy field, to achieve the effect of large heat transfer coefficient outside the tube, improve operating efficiency, and reduce initial investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

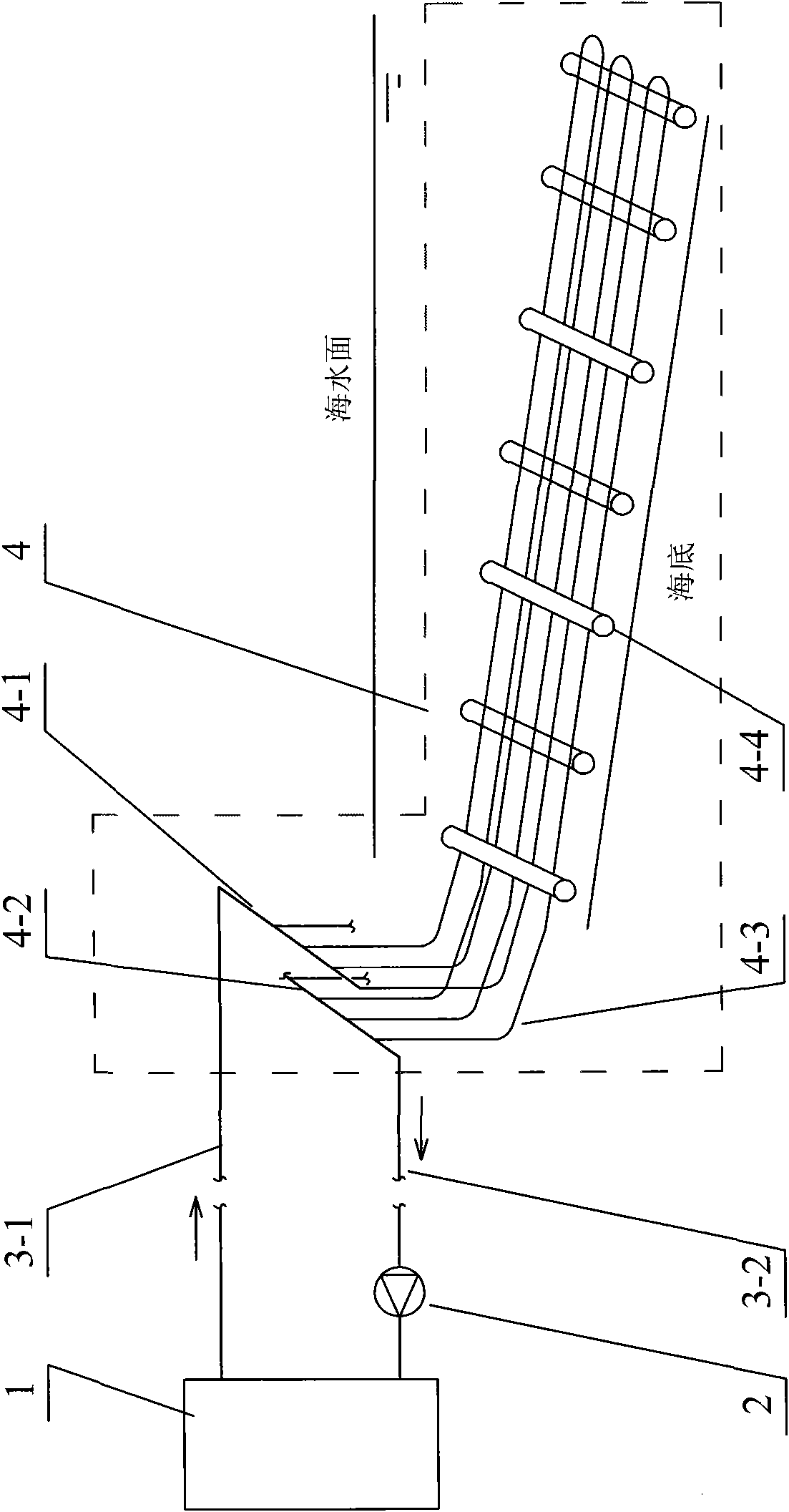

[0028] Specific implementation mode one (see figure 1 ), this embodiment is composed of heat pump unit 1, medium circulating water pump 2, medium water supply pipeline 3-1, medium return water pipeline 3-2 and long straight plastic pipe heat exchange device 4, medium water supply pipeline 3-1 and heat pump unit 1 It is connected with the water distribution pipe 4-1 of the long straight plastic pipe heat exchange device 4, the medium return water pipeline 3-2 is connected with the heat pump unit 1 and the water collection pipe 4-2 of the long straight plastic pipe heat exchange device 4, and the medium circulating water pump 2 is connected On the medium return line 3-2, the long straight plastic pipe heat exchange device 4 is composed of a water distribution pipe 4-1, a water collection pipe 4-2, a long straight engineering heat-conducting plastic pipe 4-3, and a weight 4-4. The heat-conducting plastic pipe 4-3 of the long straight project is laid back and forth along the deep ...

specific Embodiment approach 2

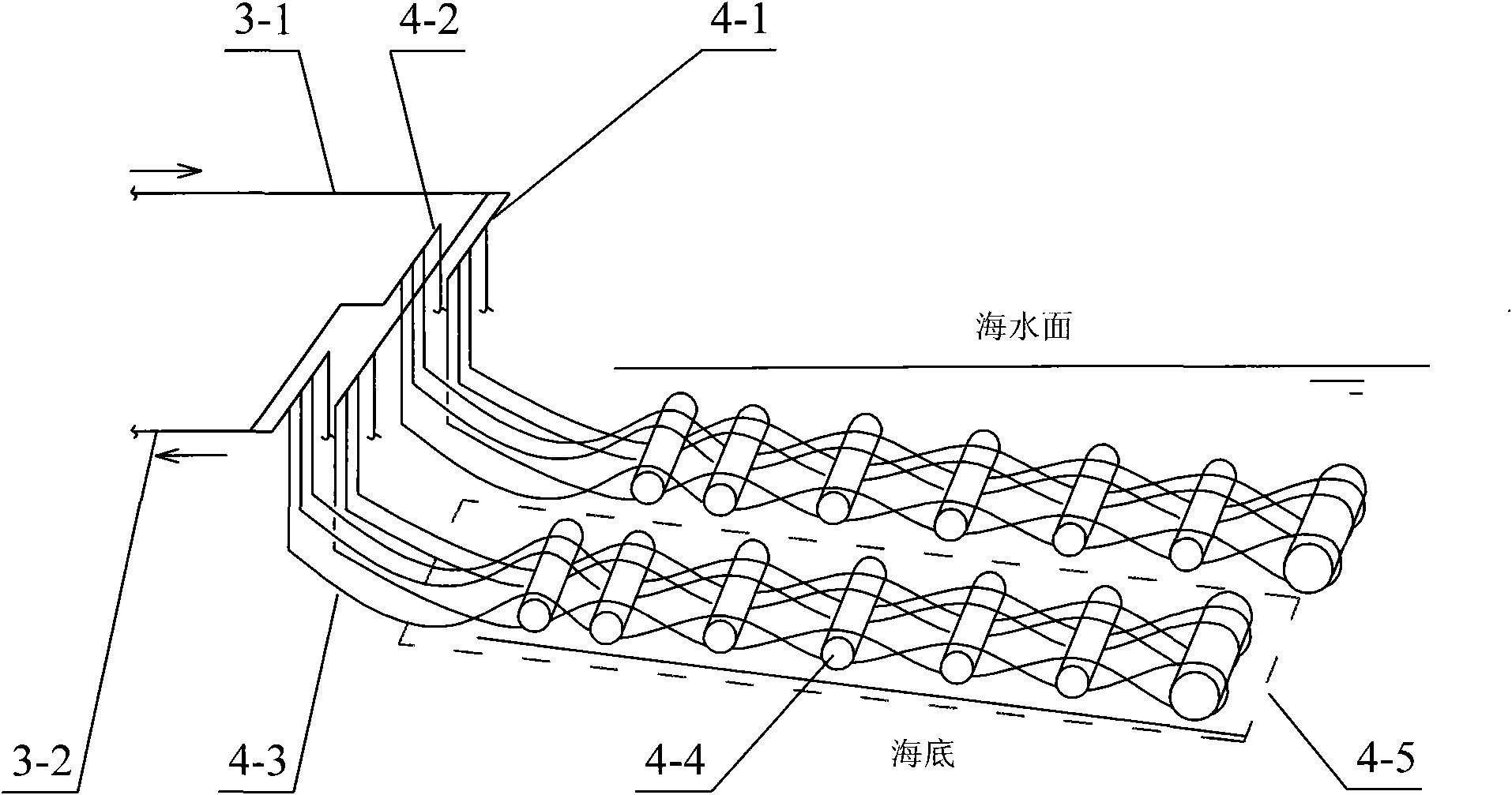

[0029] Specific implementation mode two (see figure 2 ), several long straight engineering heat-conducting plastic pipes 4-3 in the long straight plastic pipe heat exchange device 4 of the present embodiment are laid back and forth side by side in the horizontal direction to form a pipe row unit bundle 4-5, and a pipe row unit bundle 4-5 Then connect with water distribution pipe 4-1 and water collection pipe 4-2, a plurality of water distribution pipes 4-1 and water collection pipe 4-2 connect a plurality of pipe row unit tube bundles 4-5 in parallel, and weighting objects 4-4 are dispersedly arranged on the pipes On the row unit tube bundles 4-5, other composition and connection relations are the same as the specific embodiment one.

specific Embodiment approach 3

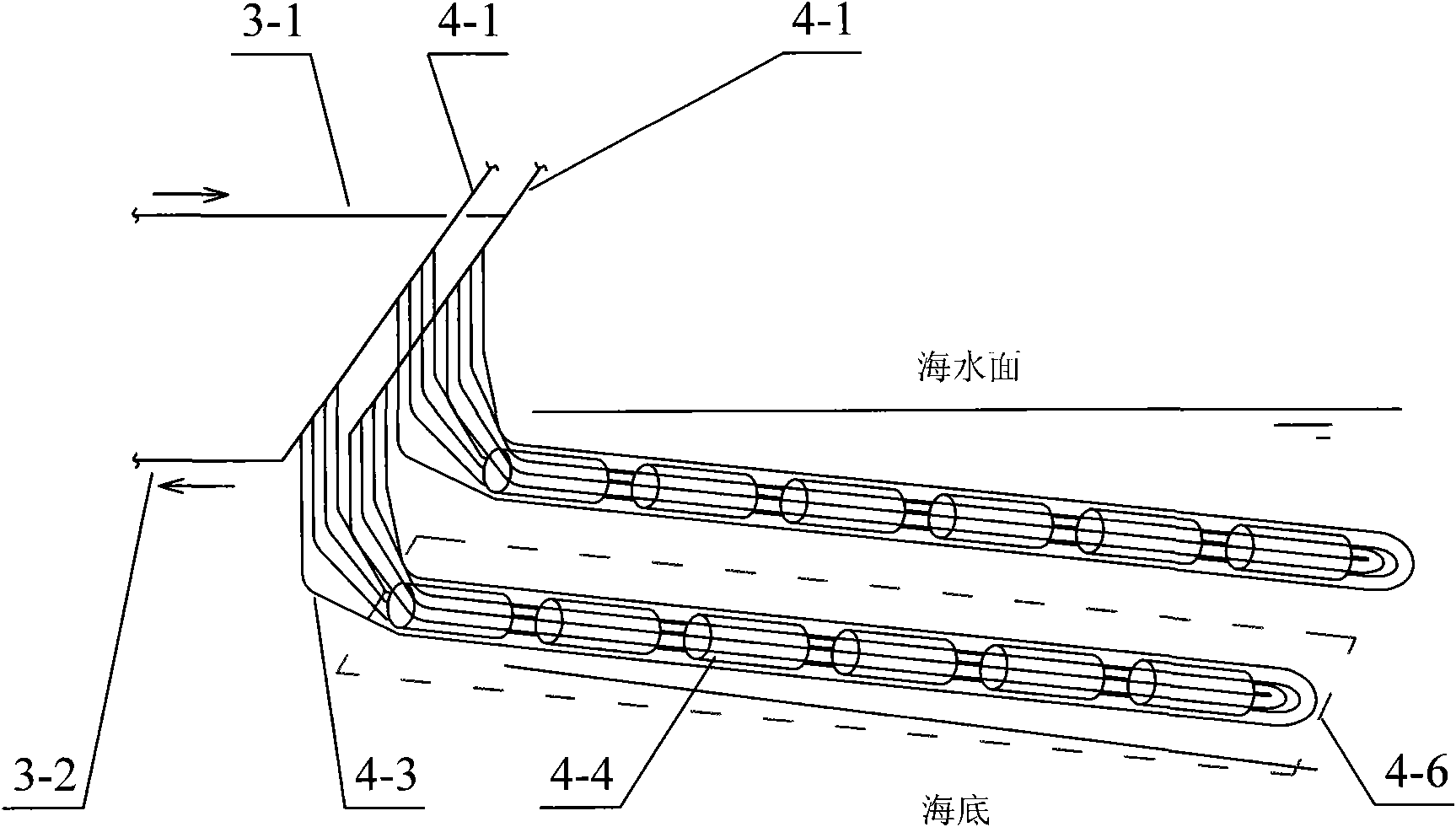

[0030] Specific implementation mode three (see image 3 ), several long straight engineering heat-conducting plastic pipes 4-3 in the long straight plastic pipe heat exchange device 4 of the present embodiment are bundled on the weight 4-4 to form a long dragon unit tube bundle 4-6, and a long dragon unit tube bundle 4-6 Connect with the water distribution pipe 4-1 and the water collection pipe 4-2 again, and a plurality of water distribution pipes 4-1 and the water collection pipe 4-2 connect a plurality of long dragon unit tube bundles 4-6 in parallel, and other composition and connection relations are the same as the specific embodiment one .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com