Method for determining optimal curing condition of thermosetting resin

A curing condition, thermosetting technology, used in color/spectral property measurement, measuring device, material analysis by optical means, etc., can solve problems such as poor mechanical properties, and achieve the effect of simplified method, fast analysis speed, and complete system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Embodiment 1: a kind of method for determining the optimum curing condition of thermosetting resin obtains according to the following method:

[0052] ① Preliminary determination of the amount of A and B added

[0053] According to the actual situation, the ratio A / B=3:1 of the two components with ideal drying conditions is preliminarily selected.

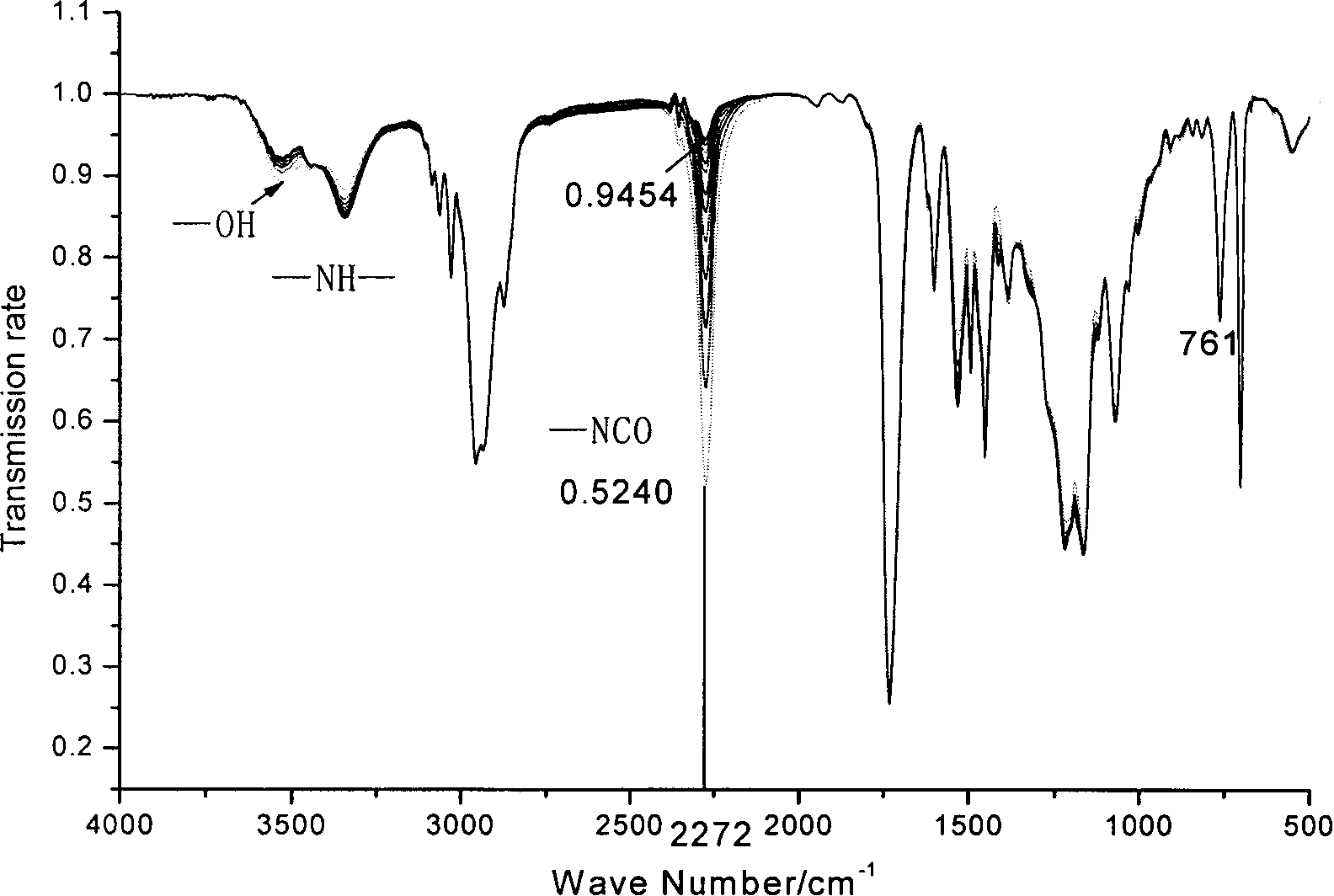

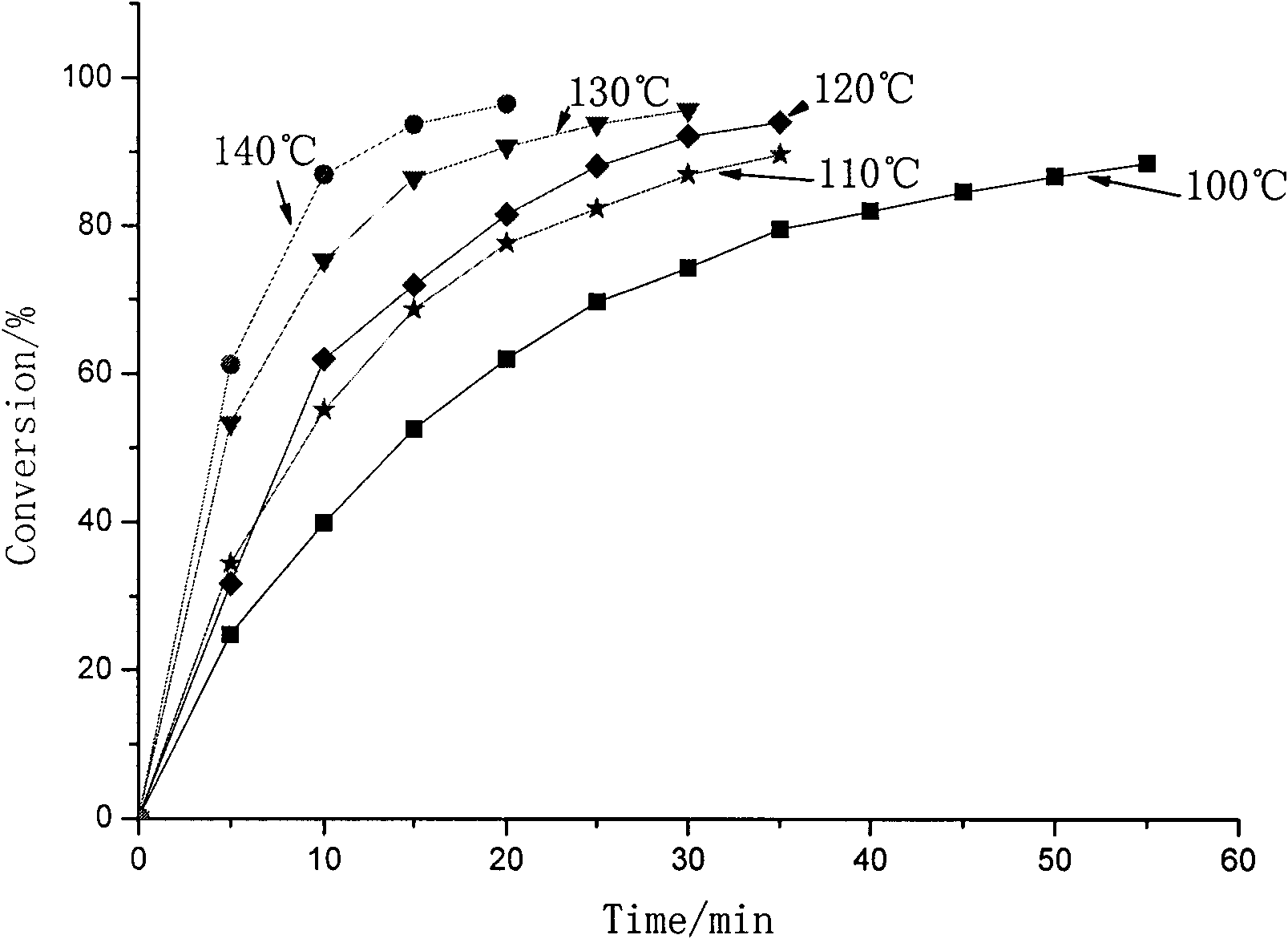

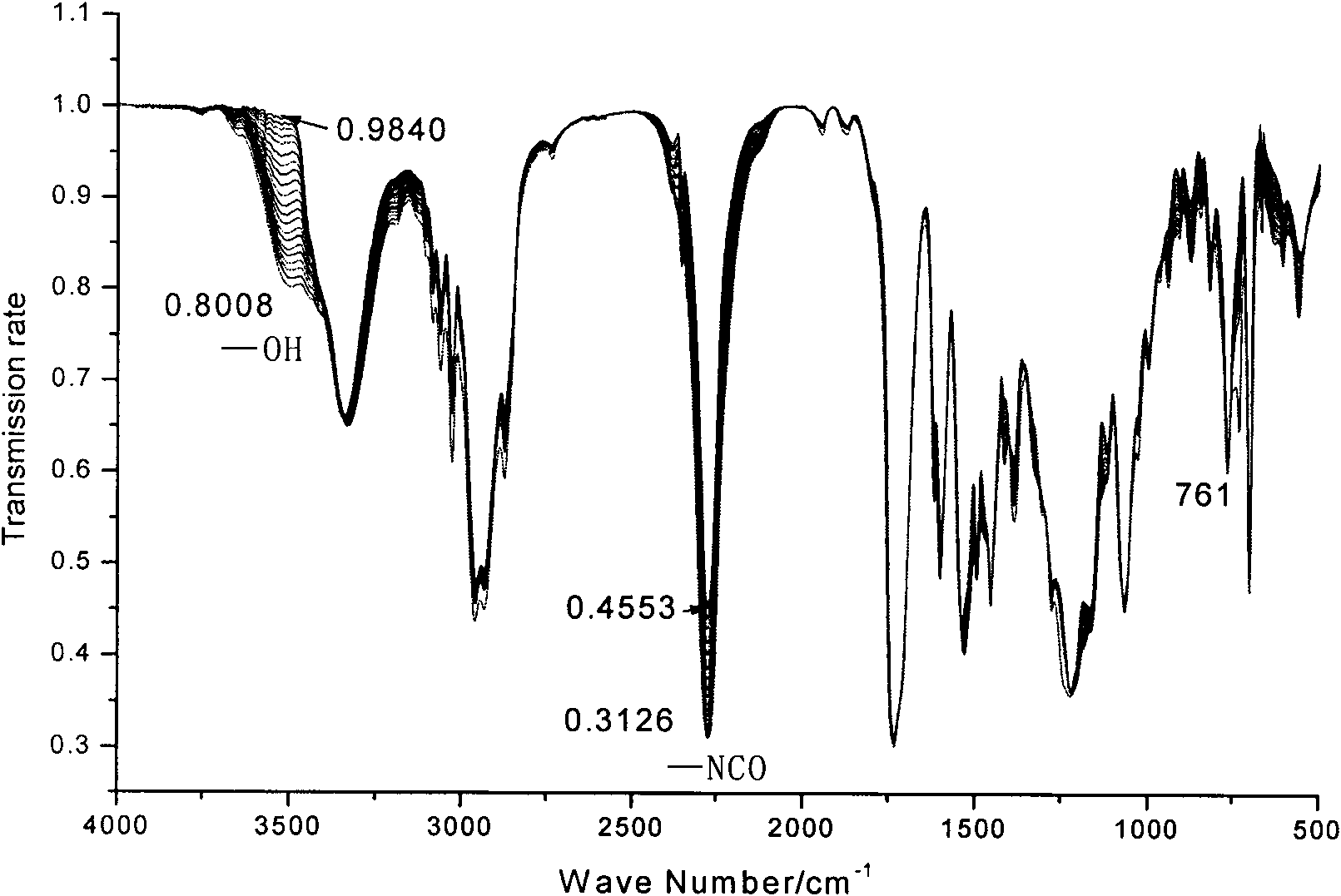

[0054] ②Consolidation process, determine the best curing temperature

[0055]Install the potassium bromide (KBr) window where the sample is placed in the "accessory", and then place the "accessory" as a whole in the optical path of the infrared spectrum sample chamber; adjust the temperature control device to raise the temperature of the inner cavity of the "accessory" to the set value Temperature; according to the mass ratio A / B=3:1, accurately weigh components A and B with an electronic balance, mix immediately, and stir evenly; take an appropriate amount of mixed resin, and apply it to the potassium bromide (KBr) in the ...

Embodiment 2

[0060] Embodiment 2: The mass ratio of components A and B of the polyurethane sample is set to be 2:1, and the rest are the same as in Embodiment 1.

Embodiment 3

[0061] Embodiment 3: The mass ratio of components A and B of the polyurethane sample is set to be 4:1, and the rest are the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Transmittance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com