Method for preparing titanium sol carrier zinc and copper ion-adsorbing antibacterial agent by microwave heating

A technology of microwave heating and titanium sol, applied in botanical equipment and methods, chemicals for biological control, biocides, etc., can solve the problems of high cost of silver-based antibacterial agents, discoloration of antibacterial materials, etc., and achieve a single solution. The effect of improving the antibacterial properties, and optimizing the synthesis conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 8mL butyl titanate (Ti(OBu) 4 ) was added dropwise into 20mL of ethanol with stirring at 50°C and mixed evenly, then 2mL of glacial acetic acid was added to obtain solution A. Then 60 mL of ethanol and 2 mL of distilled water were added with nitric acid under stirring to adjust the pH value to 1-2 to obtain solution B. Add solution B dropwise to solution A at a rate of 50-60 drops per minute, then add nitric acid to 60 mL of ethanol and 2 mL of distilled water under stirring to adjust the pH value to 2-3 to obtain solution B. Add solution B dropwise to solution A at a rate of 50-60 drops per minute, stir and adjust the pH value to 2-3, place it in a microwave oven with a power of 500-900W and heat it for 20-90s to obtain light yellow Transparent titanium sol.

Embodiment 2

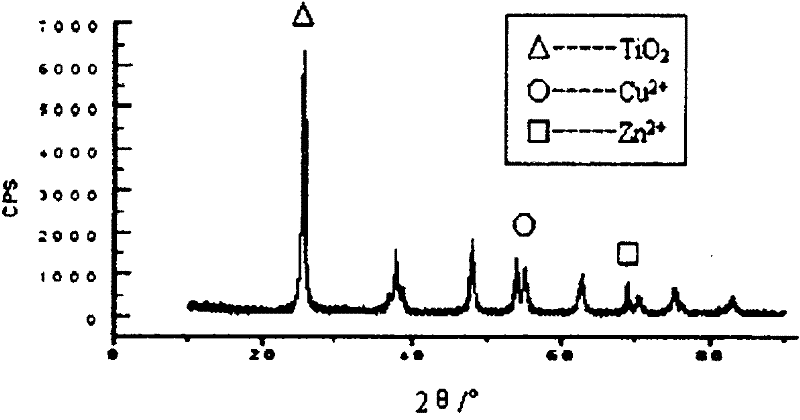

[0020] Add 0.3mol / L copper nitrate and zinc nitrate solution dropwise to the sol, and the amount of ions added is 8:100 (the molar ratio of the total number of ions to butyl titanate), that is, 1.5g ions / 100mL butyl titanate, zinc and copper ions The molar ratio of the mixture is 2:1, stirred at 30°C for 2h, and then heated by microwave for 20-50s to obtain a titanium gel adsorbing zinc and copper ions. Then place the prepared gel in a drying oven to dry to obtain a loose xerogel. After grinding, place it in a crucible and put it in a furnace for calcination at 450°C and keep it warm for 30-60 minutes. After taking it out, you can get the desired antibacterial agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com