Rolling and fitting equipment

A kind of equipment and abrasive technology, applied in the field of free abrasive finishing equipment, can solve the problems of poor processing effect, limited speed, narrow processing range, etc., and achieve the effect of saving processing time, easy to change, and saving processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

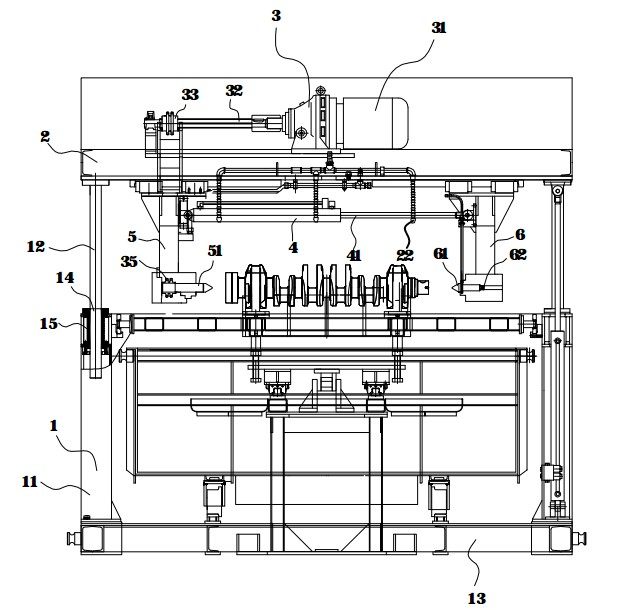

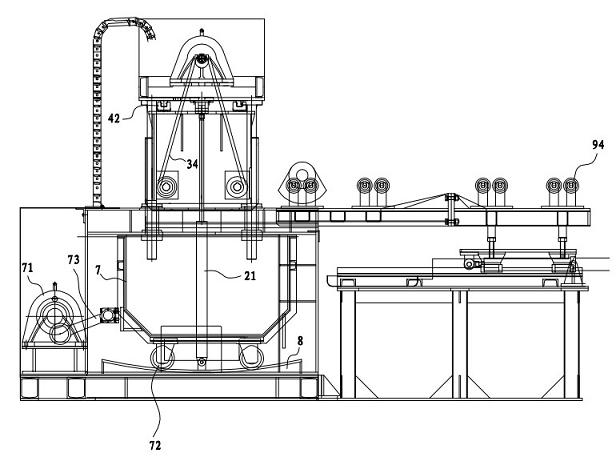

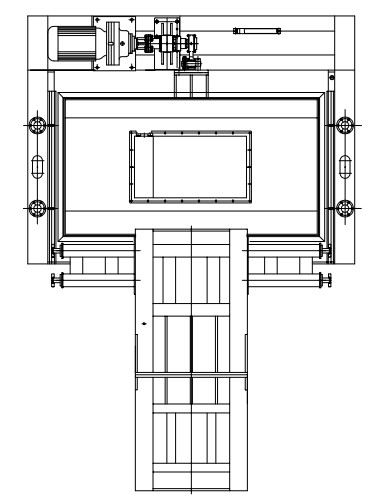

[0030] Such as Figures 1 to 4 As shown, the present invention includes a frame 1 placed on the ground. The frame includes a rectangular base 13. Two side seats 11 are fixed on both sides of the base 13. Two arc guide rails 8 are fixed on the base 11. The arc guide rails The radius of curvature is 2000mm, and the abrasive box 7 is placed on the arc guide rail 8, and the bottom of the abrasive box 7 is provided with two pairs of pulleys 72 of symmetrical distribution, and the pulley 72 and the arc guide rail 8 rolling fit. The abrasive box 7 and the connecting rod 73 are fixedly connected by bolts, the connecting rod 73 is arranged on the crank connecting rod mechanism 71 , and the crank connecting rod mechanism 71 is also fixed on the base 13 . In this way, the crank-link mechanism 71 can push the abrasive box 7 to reciprocate along the arc guide rail 8 .

[0031] Two guide post holes 14 are provided on each side seat 11, and a linear bearing 15 is housed in the guide post ho...

Embodiment 2

[0037] Similar to Embodiment 1, the main difference is that an arc-shaped guide rail 8 with a curvature radius of 2800 mm is used. The experimental data obtained are as follows:

[0038]

Embodiment 3

[0040] Similar to Embodiment 1, the main difference is that an arc-shaped guide rail 8 with a curvature radius of 3200 mm is used. The experimental data obtained are as follows:

[0041]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com