Stevia rebaudiana Bertoni extract and extraction method thereof and extraction method of rebaudioside A

An extraction method and technology of stevia rebaudiana, applied in chemical instruments and methods, sugar derivatives, sugar derivatives, etc., can solve the problems of inability to separate and obtain rebaudioside A

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

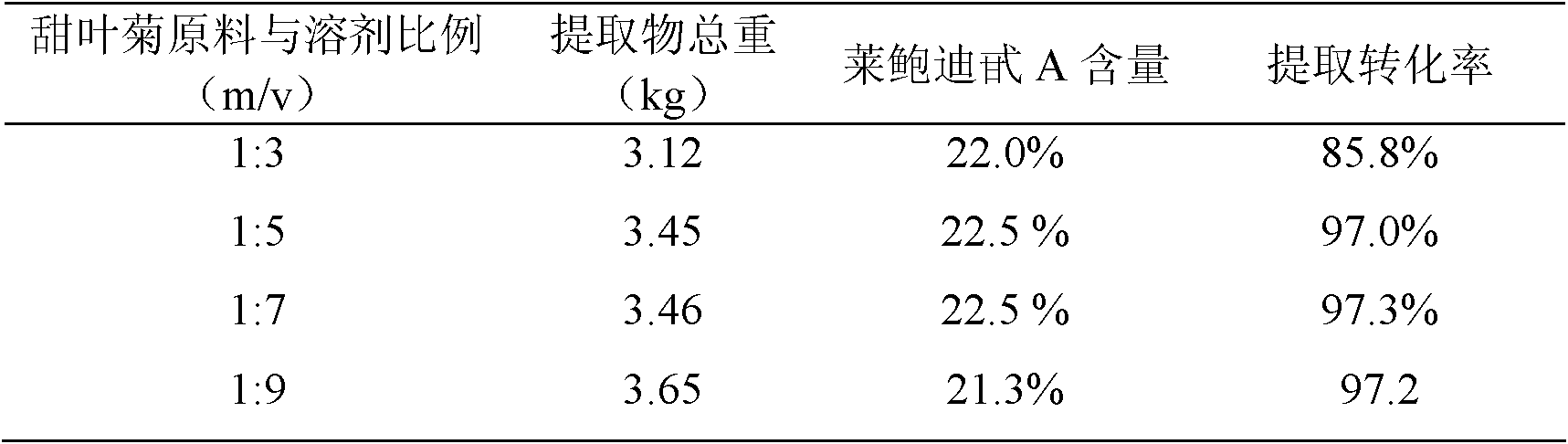

[0033] Embodiment 1 The influence of stevia rebaudiana raw material and solvent ratio on continuous countercurrent extraction

[0034] According to the weight-to-volume ratio of 1:3, 1:5, 1:7, 1:9 (m / v), 10 kg of dried Stevia rebaudiana (Stevia rebaudiana Bertohi) leaves and stems (containing 8% rebaudioside A ) and 5% (v / v) mixed solvent of water and methanol at 70°C for continuous countercurrent extraction, and the flow rate of the mixed solvent of water and methanol for every kilogram of stevia raw material is 2L / h.

[0035] Measure the volume of the extract, and quantitatively measure part of the extract, evaporate to dryness to constant weight, weigh, and take samples respectively for purity identification by HPLC. The experimental results are shown in Table 1.

[0036] The influence of table 1 stevia rebaudiana raw material and solvent ratio on continuous countercurrent extraction

[0037]

[0038] The above experimental results show that in the continuous countercurre...

Embodiment 2

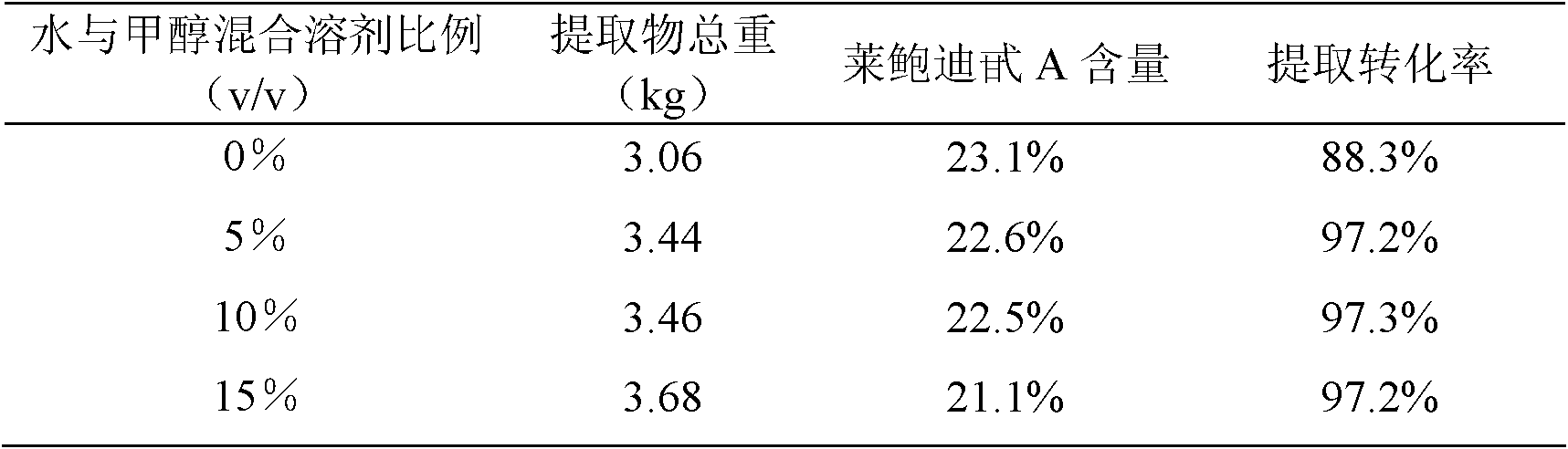

[0040] Embodiment 2 The influence of water and methanol mixed solvent ratio on continuous countercurrent extraction

[0041] 10 kg of Stevia rebaudiana Bertohi leaves and stems were mixed with 0%, 5%, 10%, 15% (v / v) water and methanol at a weight-to-volume ratio of 1:6 (m / v) The solvent is subjected to continuous countercurrent extraction at 70° C., and the flow rate of the mixed solvent of water and methanol for each kilogram of stevia raw material is 2 L / h.

[0042] Measure the volume of the extract, and quantitatively measure a part of the extract, evaporate it to constant weight, weigh it, and take samples for purity identification by HPLC. The experimental results are shown in Table 2.

[0043] Table 2 The influence of water and methanol mixed solvent ratio on continuous countercurrent extraction

[0044]

[0045] The above experimental results show that in the continuous countercurrent extraction of stevia rebaudiana raw materials, when the mixed solvent ratio of wat...

Embodiment 3

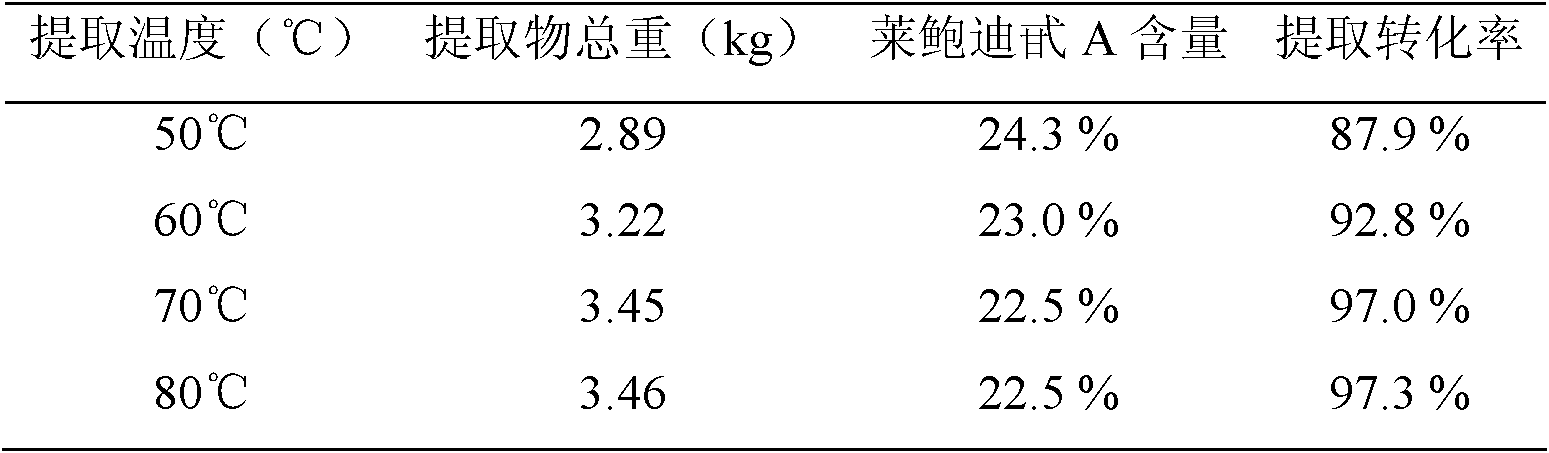

[0047] Embodiment 3 The influence of extraction temperature on continuous countercurrent extraction

[0048] According to the weight-to-volume ratio of 1:6 (m / v), 10 kilograms of stevia (Stevia rebaudiana Bertohi) leaves and stems were mixed with 7% (v / v) of water and methanol at 50°C, 60°C, and 70°C respectively. ℃, 80 ℃ for continuous countercurrent extraction, the flow rate of water and methanol mixed solvent per kilogram of stevia raw material is 2L / h.

[0049] Measure the volume of the extract, and quantitatively measure a part of the extract, evaporate to dryness to constant weight, weigh it, and take samples respectively for purity identification by HPLC. The experimental results are shown in Table 3.

[0050] Table 3 The influence of extraction temperature on continuous countercurrent extraction

[0051]

[0052] The above experimental results show that in the continuous countercurrent extraction of Stevia rebaudiana raw materials, the best extraction effect is ach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com