Aluminum zinc rare-earth hydrotalcite thermal stabilizer for PVC and application thereof

A composite thermal stabilizer and hydrotalcite technology, applied in the field of material application, can solve the problems of weakened sample transparency, poor coloring effect, poor thermal stability, etc. Effect

Inactive Publication Date: 2011-01-12

CENT SOUTH UNIV

View PDF5 Cites 13 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The ternary rare earth hydrotalcites reported in the literature are basically used in catalysts and fluorescent materials. Although there is a patent 200910303613.1 that adds Mg-Al rare earth hydrotalcites to PVC as a heat stabilizer, the Mg-Al hydrotalcites In the early stage, the thermal stability is poor and the coloring effect is poor. Because of the Mg element itself, when it is added to PVC, the transparency of the sample will be weakened and the color will turn yellow. To a large extent, it cannot meet the colorless and tasteless plastic in the food industry. Require

Zn-Al hydrotalcite has good transparency and good thermal stability in the early stage, but zinc burning will occur in the later stage

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

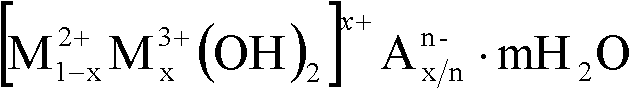

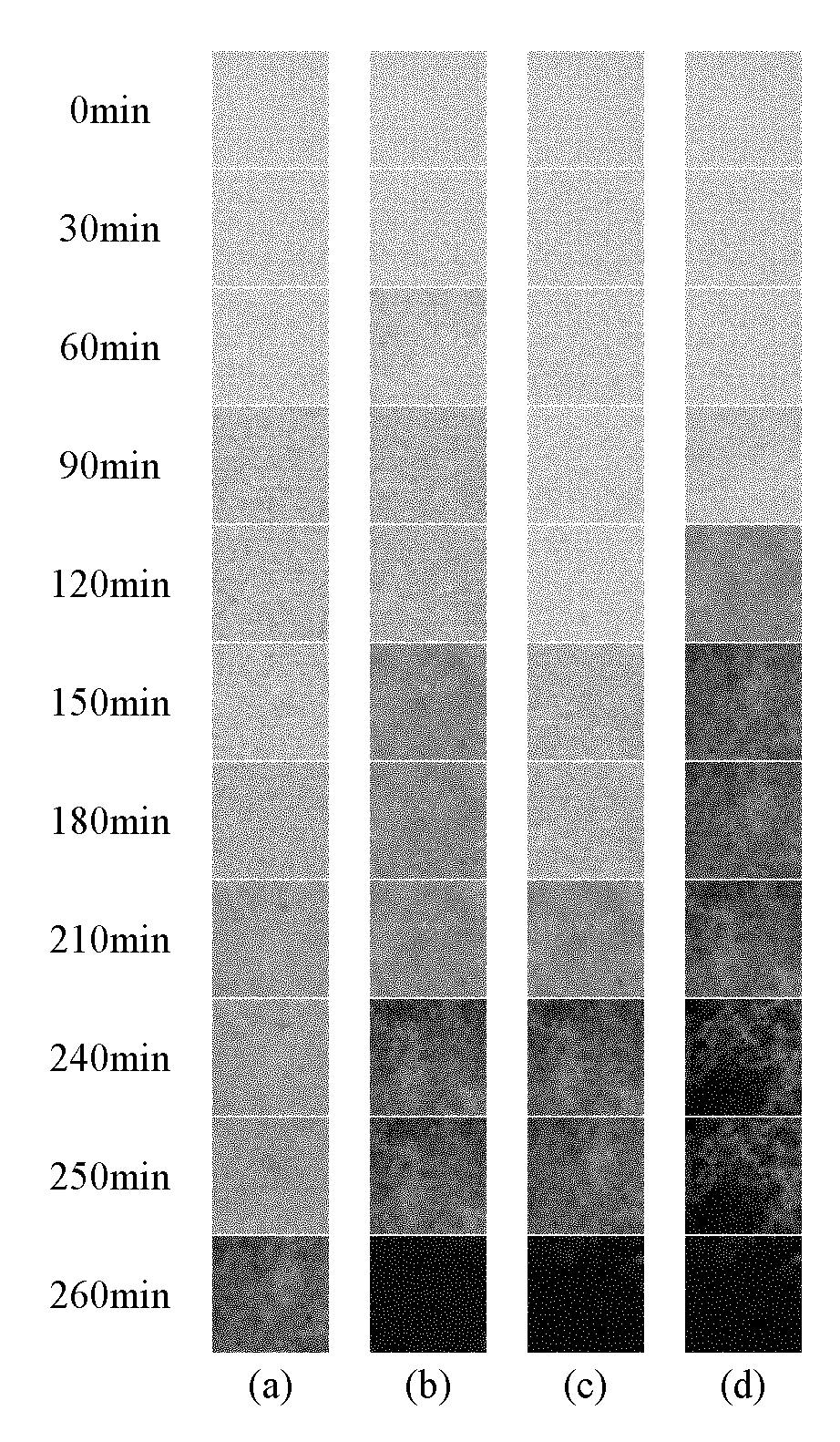

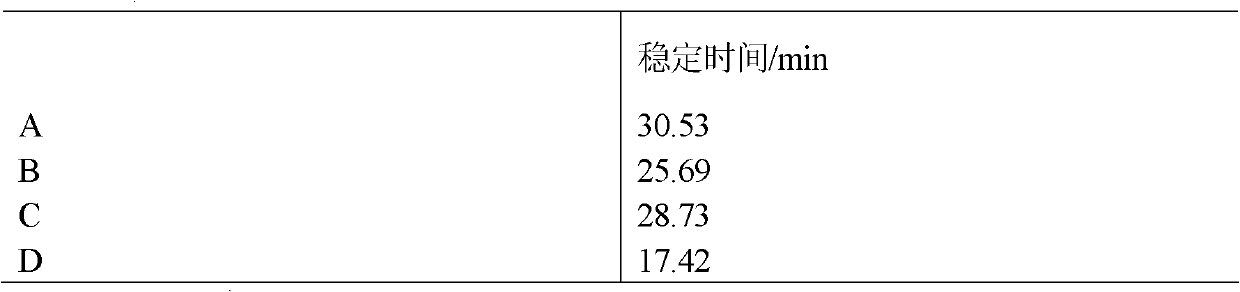

The invention relates to an aluminum zinc rare-earth hydrotalcite compound thermal stabilizer for PVC and application thereof. The compound thermal stabilizer is compounded from aluminum zinc rare-earth hydrotalcite and proper amounts of calcium soap and beta-diketone in optimal proportions. A sodium stearate wet process is used for modifying the aluminum zinc rare-earth hydrotalcite and enhances the compatibility thereof with the PVC; the invention firstly adds the compounded modified aluminum zinc rare-earth hydrotalcite, the calcium soap and the beta-diketone into the PVC to serve as the compound thermal stabilizer. The static thermal ageing test indicates that the thermal stabilization time (the turning-black time of a sample) of the optimally compounded thermal stabilizer reaches more than 240 minutes. The thermal stabilizer can enhance the product transparence, has the advantages of favorable stability, simple and practicable preparation process, no toxicity, high efficiency and favorable weatherability, and effectively prevents zinc erosion.

Description

technical field The invention relates to a zinc-aluminum rare earth hydrotalcite composite heat stabilizer for polyvinyl chloride and its application, belonging to the field of material application. Background technique Under the influence of high temperature and high heat, polyvinyl chloride (PVC) will undergo a catalytic degradation reaction to remove HCl, which will affect its performance and bring difficulties to processing. Therefore, a certain heat stabilizer must be added before use to alleviate its degradation within a certain period of time. There are many kinds of heat stabilizers, but most of them are toxic or expensive, so it is of great significance to develop a cheap, non-toxic and efficient heat stabilizer. Hydrotalcite heat stabilizer is a kind of non-toxic inorganic auxiliary stabilizer developed by Kyowa Chemical Company in Japan in the 1980s. Because of its unique structure and performance, it has been highly valued by researchers at home and abroad, an...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L27/06C08K13/06C08K3/26C08K5/07C08K5/098C08K5/12

Inventor 杨占红陈红燕温润娟易师

Owner CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com