Uniaxial single spindle box of high-speed needling machine

A technology of spindle box and acupuncture machine, applied in acupuncture machine, transmission box, mechanical equipment and other directions, can solve the problems of unfavorable lubricating oil sealing, uneven force, excessive volume of the spindle box, etc., to meet the requirements of design and use requirements, easy installation and maintenance, improving the effect of unreasonable structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

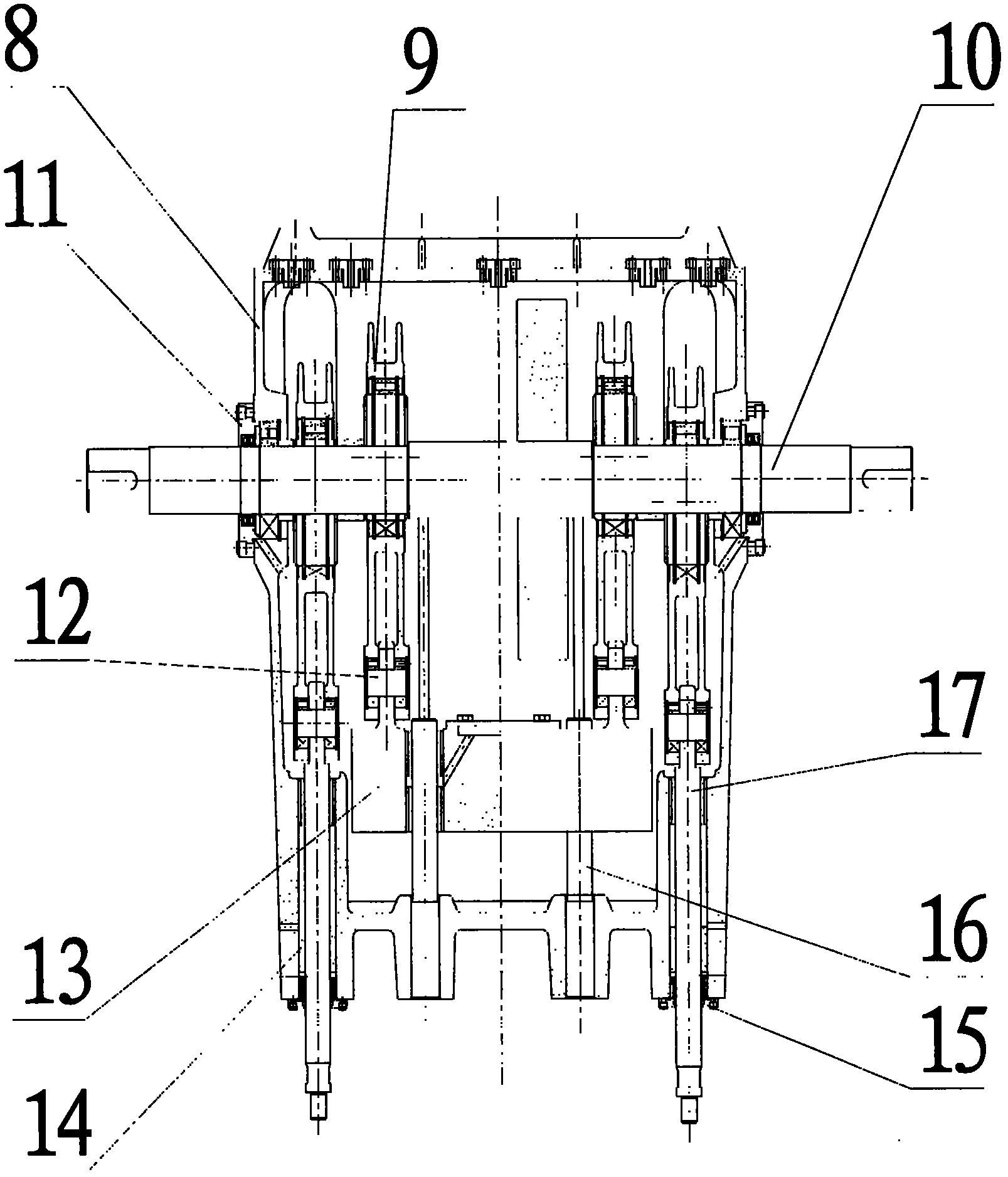

[0021] combine Figure 4 , Figure 5 , a single-axis single headstock of the present invention, including a headstock body 22, a headstock cover 18, a camshaft 21, a first connecting rod 23, a second connecting rod 32, a first connecting rod pin 24, a second connecting rod Rod pin 36, push rod 30, guide rod 39, first guide sleeve 26, second guide sleeve 40, small sliding sleeve 27, spindle end cover 20, lower end cover 28, lower boring cover 41, first roller bearing 19, Second roller bearing 33, third roller bearing 25, fourth roller bearing 37, balance weight 38, counterweight 35;

[0022] The headstock cover 18 is fixedly connected on the top of the headstock 22 by screws, the camshaft 21 is fixed on the headstock through the roller bearing and the head cover 20, and a spacer 34 is arranged between the roller bearing and the head cover 20, and the cam shaft The flywheel 31 is fixedly connected on the shaft 21, and the first roller bearing 19 is arranged in the hole of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com