Coal bunker material level measuring method and system based on stereo vision

A material level measurement, stereo vision technology, applied in liquid/fluid solid measurement, measurement device, engine lubrication, etc., to achieve the effect of easy deployment, easy expansion, and strong initiative

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The specific implementation of the present invention will be described below in conjunction with the accompanying drawings.

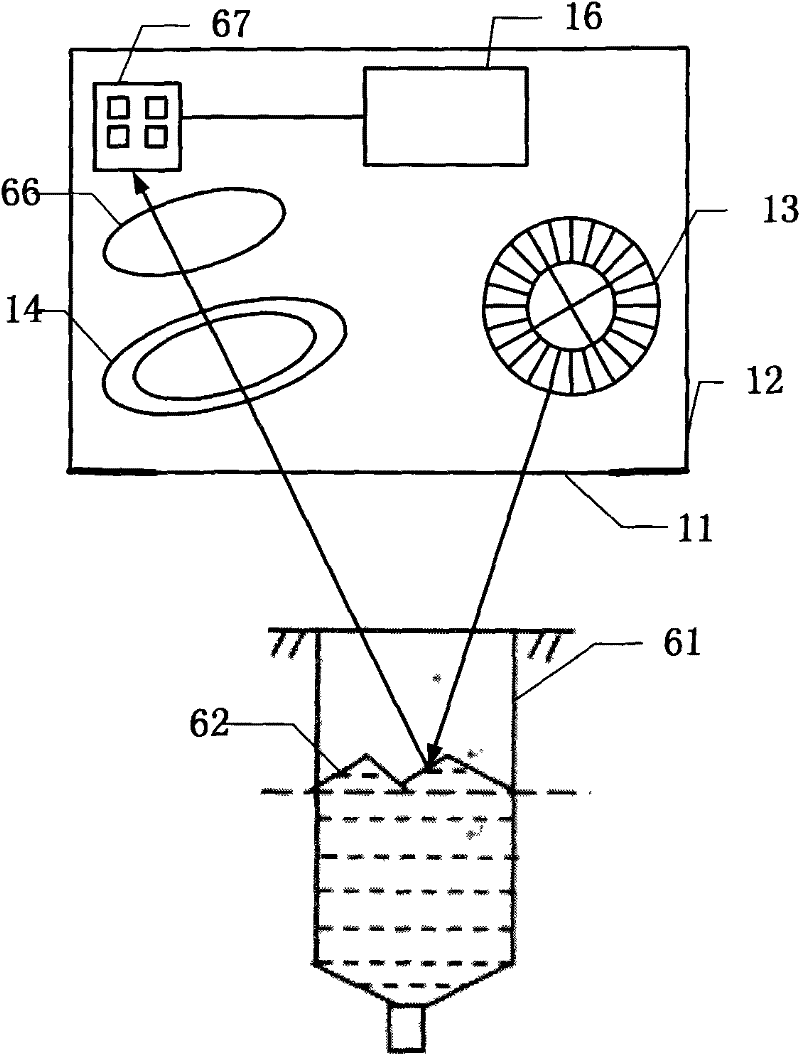

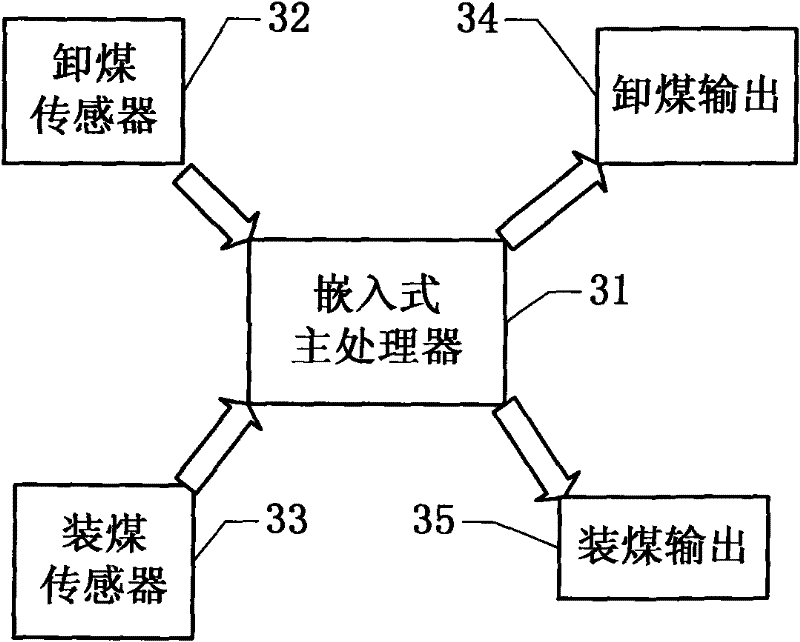

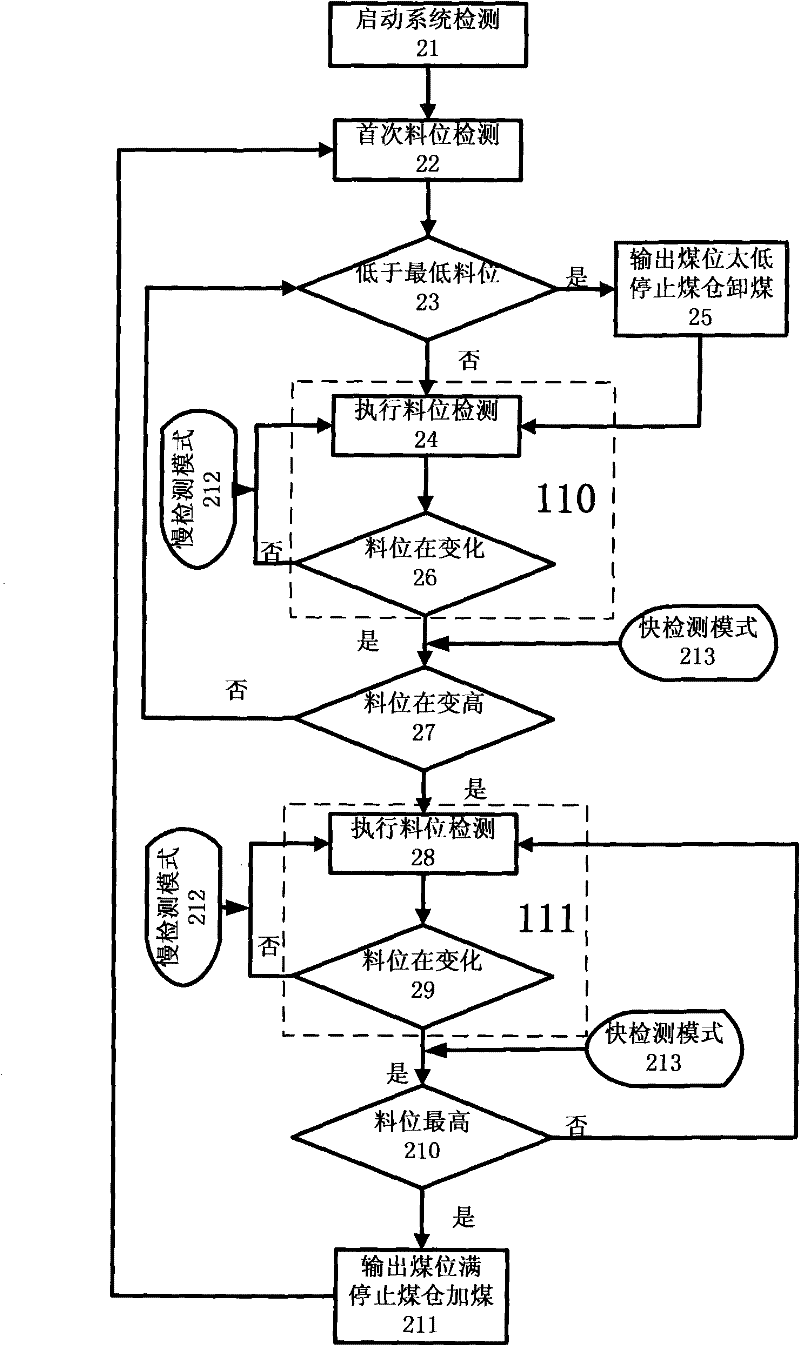

[0046] In order to improve the initiative of coal bunker material level measurement, high precision, real-time acquisition of coal depth information in coal bunker, and easy deployment, the present invention provides a coal bunker material level measurement method and system based on stereo vision; optical subsystem It is composed of an embedded processing subsystem 16, a coal unloading sensor 32, a coal loading sensor 33 and a flameproof enclosure 12 with windows. The optical subsystem mainly includes a light source module 13, a depth perception visual sensor 67, a ring light meter 14, and a lens 66; the embedded processing subsystem mainly includes an embedded main processor U11, a memory U12, an image acquisition module P3, and the like.

[0047] The working principle of the system is that the light emitted by the light source module 13 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com