Square-core multi-core fiber having different fiber core refractive indexes and preparation method

A different, multi-core optical fiber technology, applied in cladding optical fiber, glass manufacturing equipment, manufacturing tools, etc., can solve the problem of different refractive index of the fiber core, and achieve the effect of simple preparation process, convenient acquisition and flexible design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The invention provides a method for preparing a square-core multi-core optical fiber with different core refractive indices. The square-core multi-core optical fiber is composed of a cladding layer and several square-shaped optical fiber cores with small refractive index differences.

[0024] The preparation process of the optical fiber preform is realized by the following method: first, several kinds of large-diameter single-mode optical fiber cores with different refractive indices are prepared by the MCVD method, and several optical fiber cores of the same length are cut off to remove the coating layer spare.

[0025] Then select the outer quartz glass tube, the inner quartz glass tube and the solid quartz glass rod of appropriate size. According to the specifications of the multi-core optical fiber end face, the inner quartz tube is radially cut into a symmetrical end face structure and the radial surface of the cut glass tube is ground. The size of the cut high-pur...

specific Embodiment approach

[0036] Several types of large-diameter single-mode optical fiber cores with small differences in refractive index are prepared by MCVD method, and several optical fiber cores of the same length are cut off to remove the coating layer for later use.

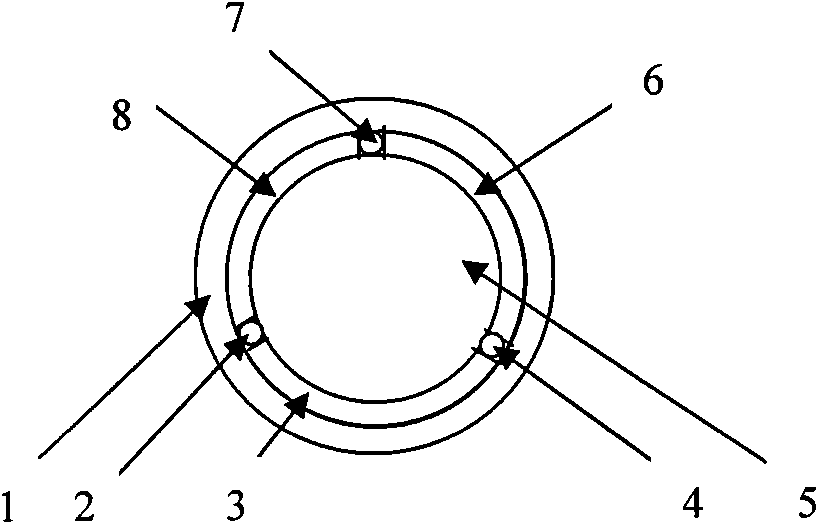

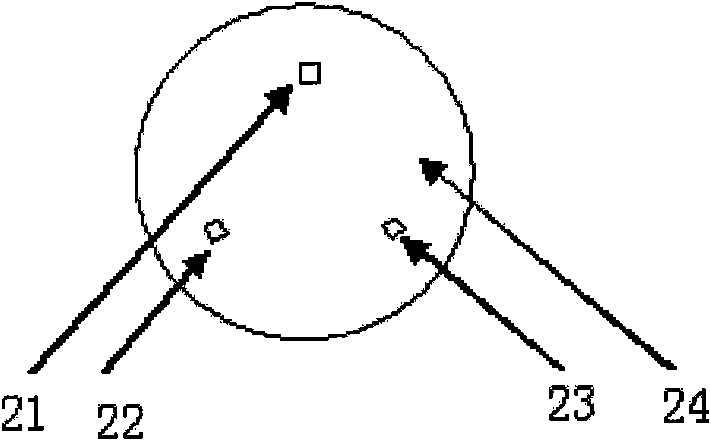

[0037] Preparation of equilateral triangular three-core optical fiber preform (such asfigure 1 shown). First, use a glass cutting machine to cut the high-purity quartz glass inner casing with a diameter equal to the inner diameter of the high-purity quartz glass outer casing 1 into three equal parts in the radial direction, and then grind the cut surface of each high-purity quartz glass tube to make three parts. A block of high-purity glass tube components 3, 6, 8, the size of the three high-purity glass tube components should be equal to the diameters 2, 4, 7 of the three optical fiber cores to be inserted. The high-purity solid-core quartz glass rod 5, three high-purity quartz components, and three optical fiber cores with sligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com