Absorbent

An absorbent and binder technology, applied in the field of metal sulfide absorbents, can solve the problems of reduced mercury capacity, difficult absorbent discharge, and long time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

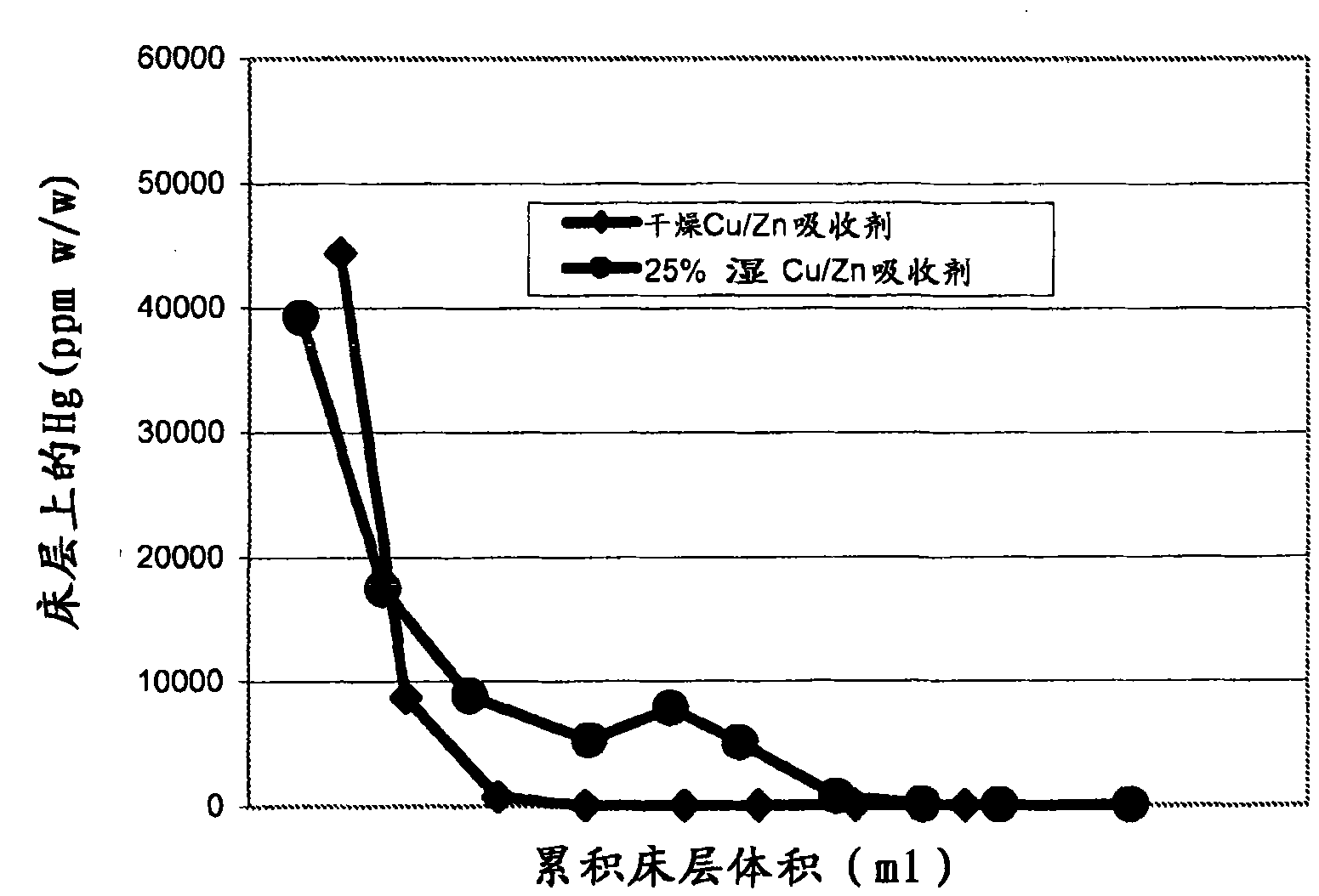

[0048] Embodiment 1 (comparison)

[0049] To assess the problems posed by the presence of water, 25 ml of 1-2 mm sized granulated absorbent containing sulphided copper and zinc compounds, an alumina carrier and a single cement binder were filled into a tubular laboratory-scale absorbent vessel (18 mm inner diameter ). The sulphided absorber had a copper content of 45% by weight (as oxide) and a zinc content of 22% by weight (as oxide).

[0050] The lower part of the bed consisted of 25% by volume of pre-soaked absorbent. The material was submerged in demineralized water for 30 minutes at ambient temperature, after which the water was decanted and the particles were dried to the touch with absorbent paper. The remaining upper portion of the bed was 75% by volume dry material. Use n-hexane saturated to about 1ppm (w / v) with elemental mercury at ambient temperature (about 20°C) for 7.0hr -1 A liquid hourly space velocity (LHSV) of 1000 was passed upward through the bed for ...

Embodiment 2

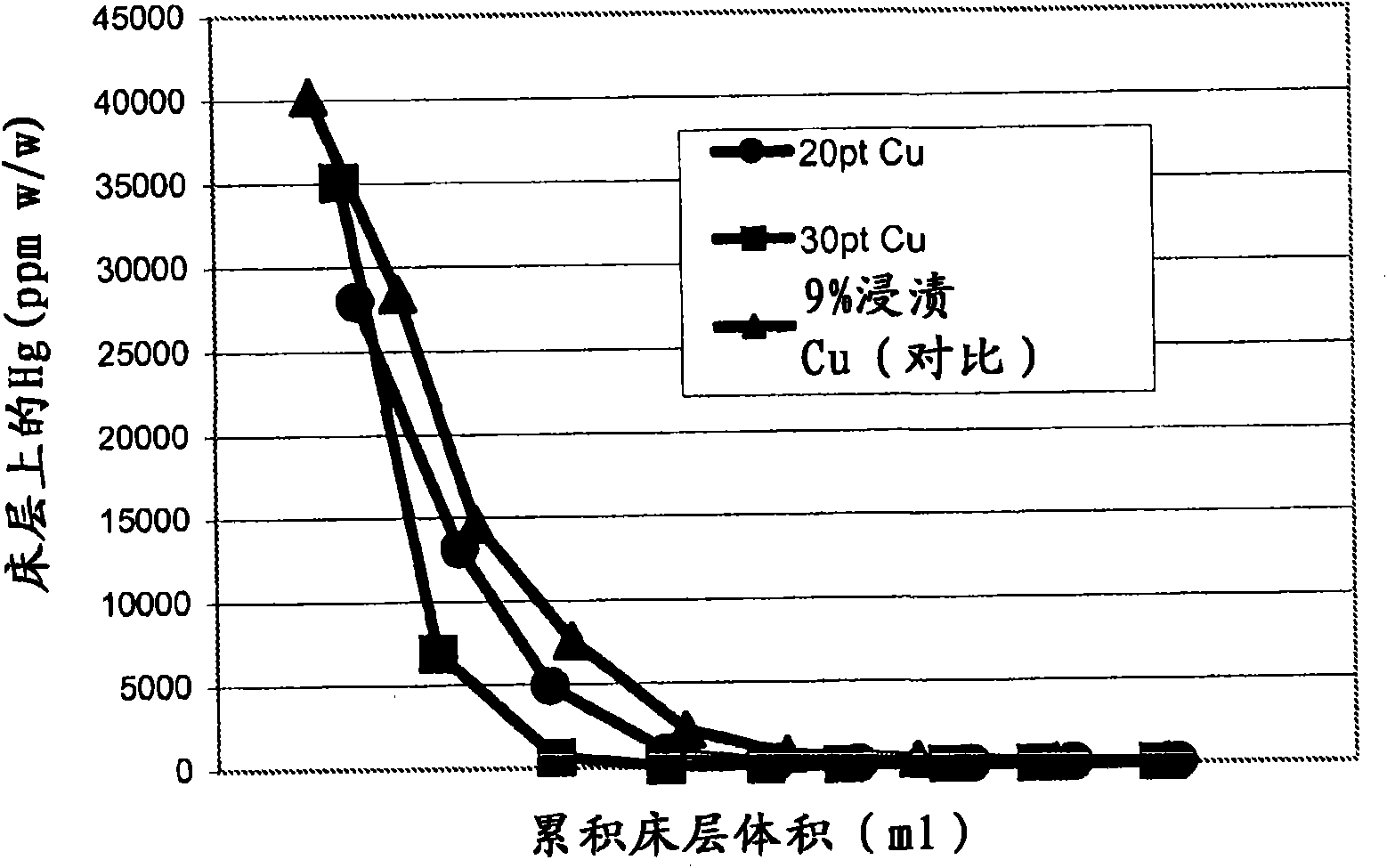

[0056] Embodiment 2 (dry test)

[0057] Absorbent precursor compositions were prepared in a granulator with the following compositions:

[0058] 20 or 30 parts by weight of quick-drying basic copper carbonate,

[0059] 80 or 70 parts by weight of alumina trihydrate,

[0060] 14 parts by weight binder comprising 10 parts calcium aluminate cement with a CaO content of about 40 wt % plus 4 parts attapulgite clay.

[0061] The granules were dried in air at 105° C. for 16 hours after 2 hours at ambient temperature (about 20° C.). The resulting particles range in size from 1-5 mm.

[0062] The granular material is in the laboratory in 1% H 2 sulfurized to saturation in S to produce an active absorbent.

[0063] The sulphurized absorbent was run in the test as described in Example 1, although in each case it was run dry without pre-soaking. The test was repeated on a commercially available presulfided 9 wt% Cu (as oxide) impregnated alumina absorbent. The results are depicte...

Embodiment 3

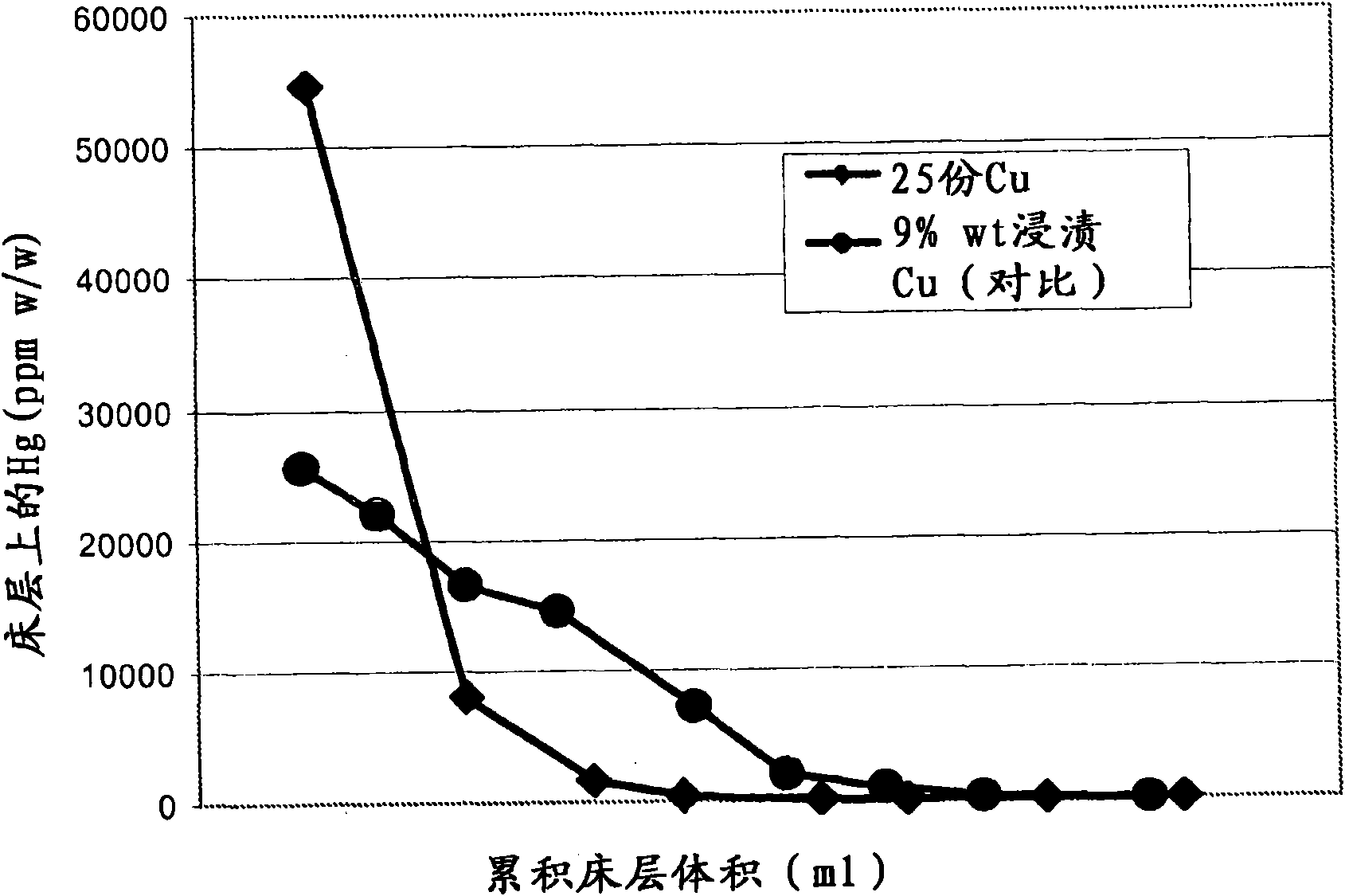

[0064] Embodiment 3 (humidity test)

[0065] Absorbent precursor compositions were prepared in a granulator with the following compositions:

[0066] 25 parts by weight of quick-drying basic copper carbonate,

[0067] 75 parts by weight of alumina trihydrate,

[0068] 14 parts by weight binder comprising 10 parts calcium aluminate cement with a CaO content of about 40 wt % plus 4 parts attapulgite clay.

[0069] The granules were dried in air at 105° C. for 16 hours after 2 hours at ambient temperature (about 20° C.). The resulting particles range in size from 1-5 mm.

[0070] The granular material is in the laboratory in 1% H 2 sulfurized to saturation in S to produce an active absorbent.

[0071] The sulfided absorbent was run as tested in Example 1 with the first 25 vol% of the bed presoaked in demineralized water. The test was repeated on a commercially available pre-sulfided 9 wt% Cu (as oxide) impregnated alumina absorbent, again where the first 25 vol% of the be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com