Double-direction automatic profiling turning machine

A profiling turning and automatic technology, which is applied in the direction of woodworking lathes, wood processing equipment, manufacturing tools, etc., can solve the problems that the accuracy and size of the workpiece cannot be guaranteed, the labor intensity of the operator is high, and the non-processing time of the machine tool is long. The effect of strengthening rigidity, reducing labor intensity and improving precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

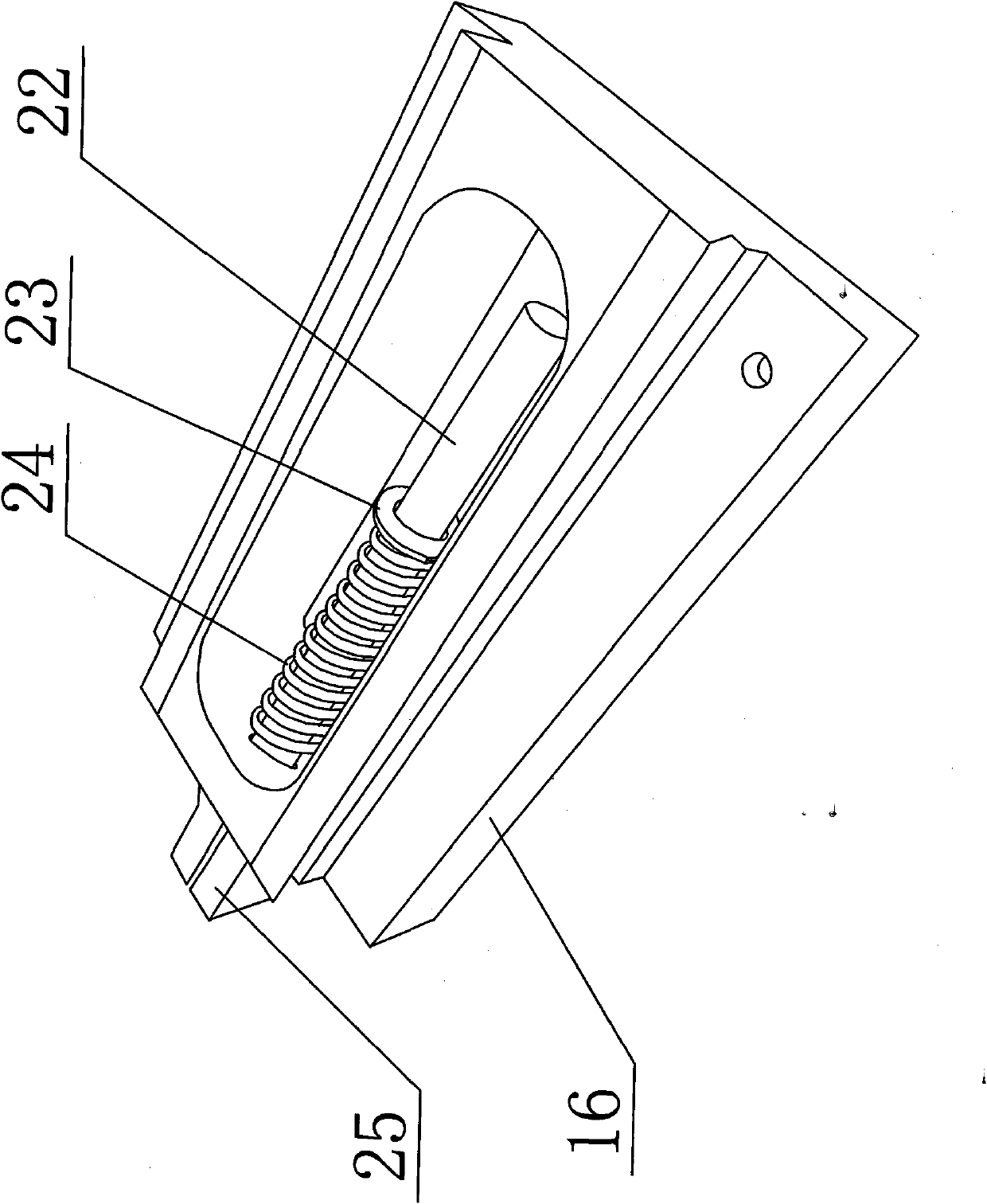

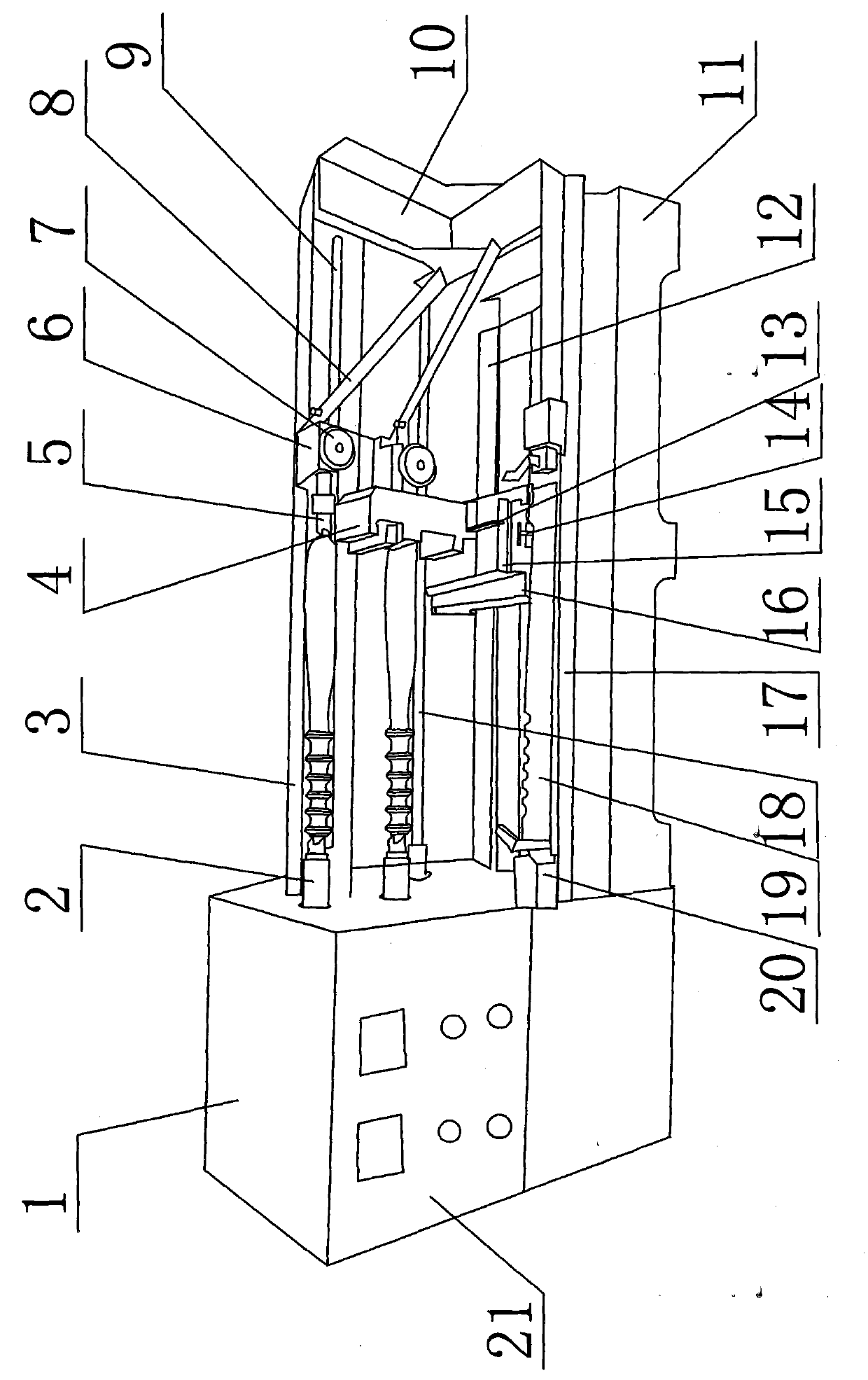

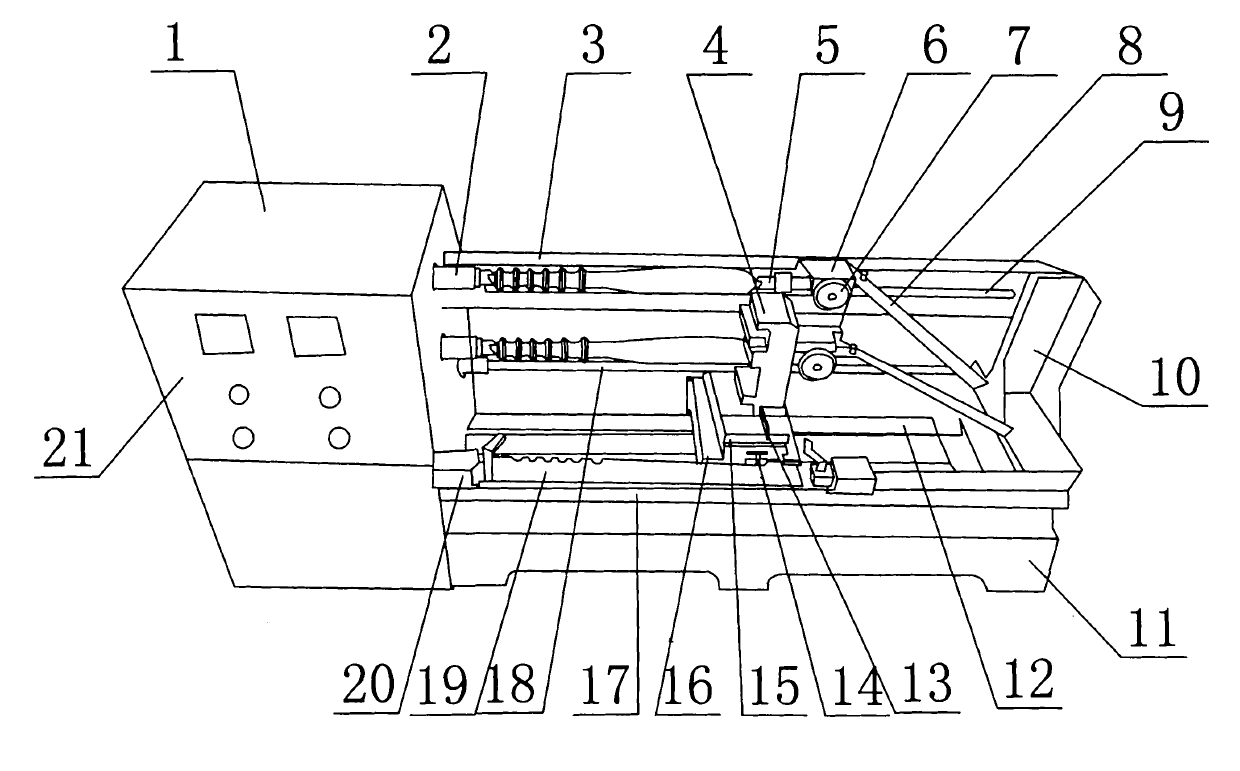

[0030] Such as figure 1 , 2 As shown, the two-way automatic profiling turning machine of the present invention includes a bed 11, a transverse guide 12 is provided on the bed 11, a headstock 1 and a tail support 10 are installed on both ends of the bed 11, and the headstock 1 is provided There are a control panel 21 and two main shafts 2. The control panel 21 is equipped with various switches. A transmission screw 18 is installed between the main shaft box 1 and the tail support 10. The large carriage 16 is connected to the transmission through the screw nut base 25 The screw rod 18 is connected, the chute on the bottom surface of the large carriage 16 is matched with the horizontal guide rail 12, a small carriage 15 is installed on the large carriage 16, and the small carriage 15 is fixedly connected with a knife holder 4 and a knife holder 4. There are two tool installation positions.

[0031] A cross beam 3 and a profiled beam 17 are also installed between the spindle box 1 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com